Support bearing of a vibration damper in a wheel suspension of a vehicle

一种车轮悬架、支承座的技术,应用在悬架、弹性悬架、车辆部件等方向,能够解决直径大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

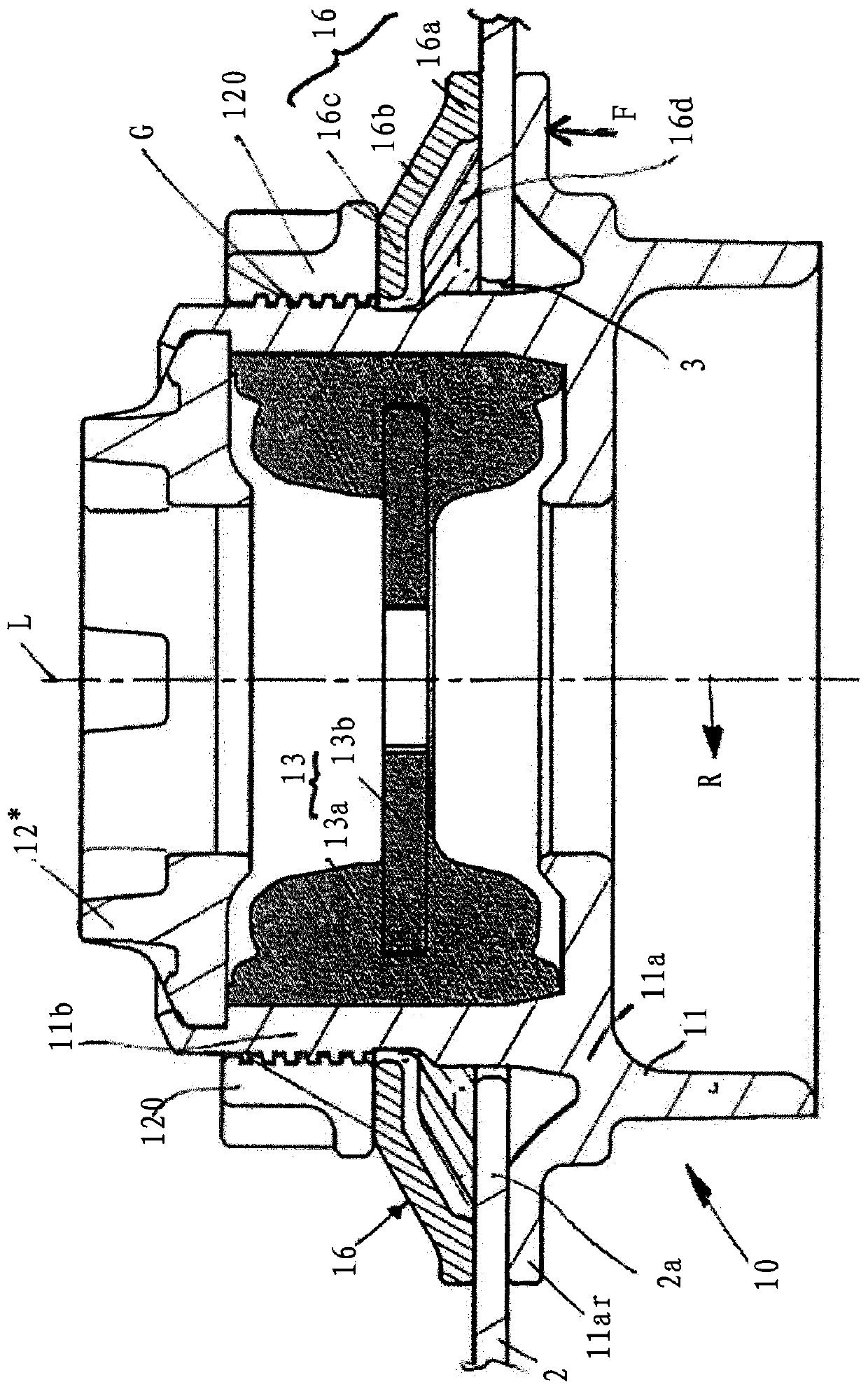

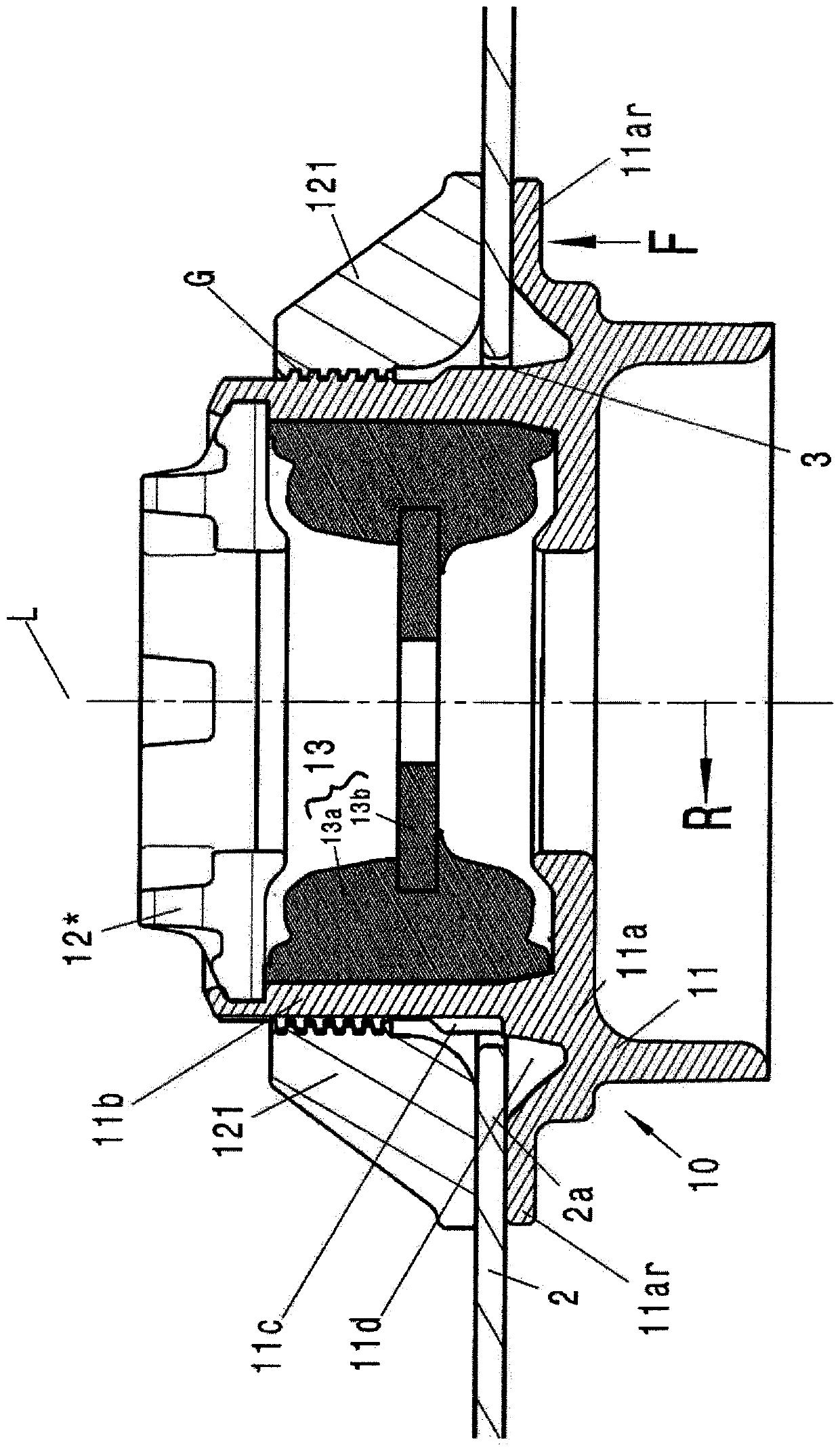

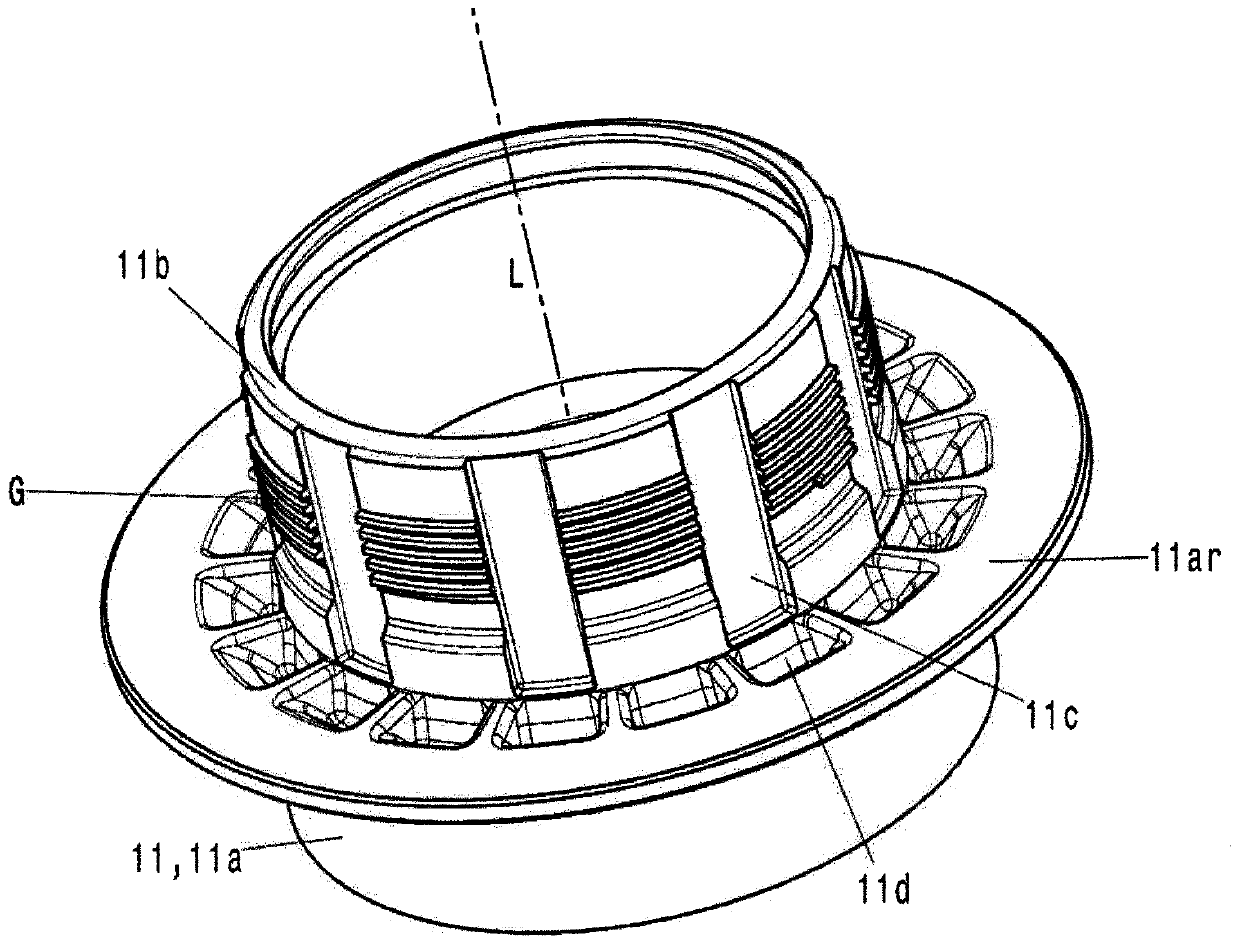

[0016] first refer to attached figure 1 , 2a , only the support seat 10 for the piston rod of the common shock absorber in the wheel suspension of the double-track vehicle is shown in said accompanying drawing, but the above-mentioned piston rod is not shown, and the piston rod is shown along the The longitudinal axis L runs in the direction and is, as usual, the axis of symmetry or axis of rotation of an approximately rotationally symmetrical bearing 10 via which the piston rod is supported or mounted or fastened to the body structure 2 of the vehicle. For this purpose, the body structure 2 , shown only very incompletely, is generally designed, for example, as a so-called strut cap and has a circular through-opening 3 , in which is arranged a valve, identified as a whole by the reference numeral 10 . The bearing seat for the shock absorber.

[0017] The components of the bearing 10 are in particular the bearing flange 11, the basically usual bearing cover 12* and here also th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com