Processing technology of quick-frozen chestnut kernels

A processing technology, a technology of quick-frozen chestnut kernels, which is applied in the directions of preservation of seeds by freezing/cooling, food processing, shelling, etc., can solve the problems of destroying the natural shape of chestnut kernels, affecting the eating experience, and inconvenient chestnut shelling process, etc. Achieve the effect of extending storage time and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

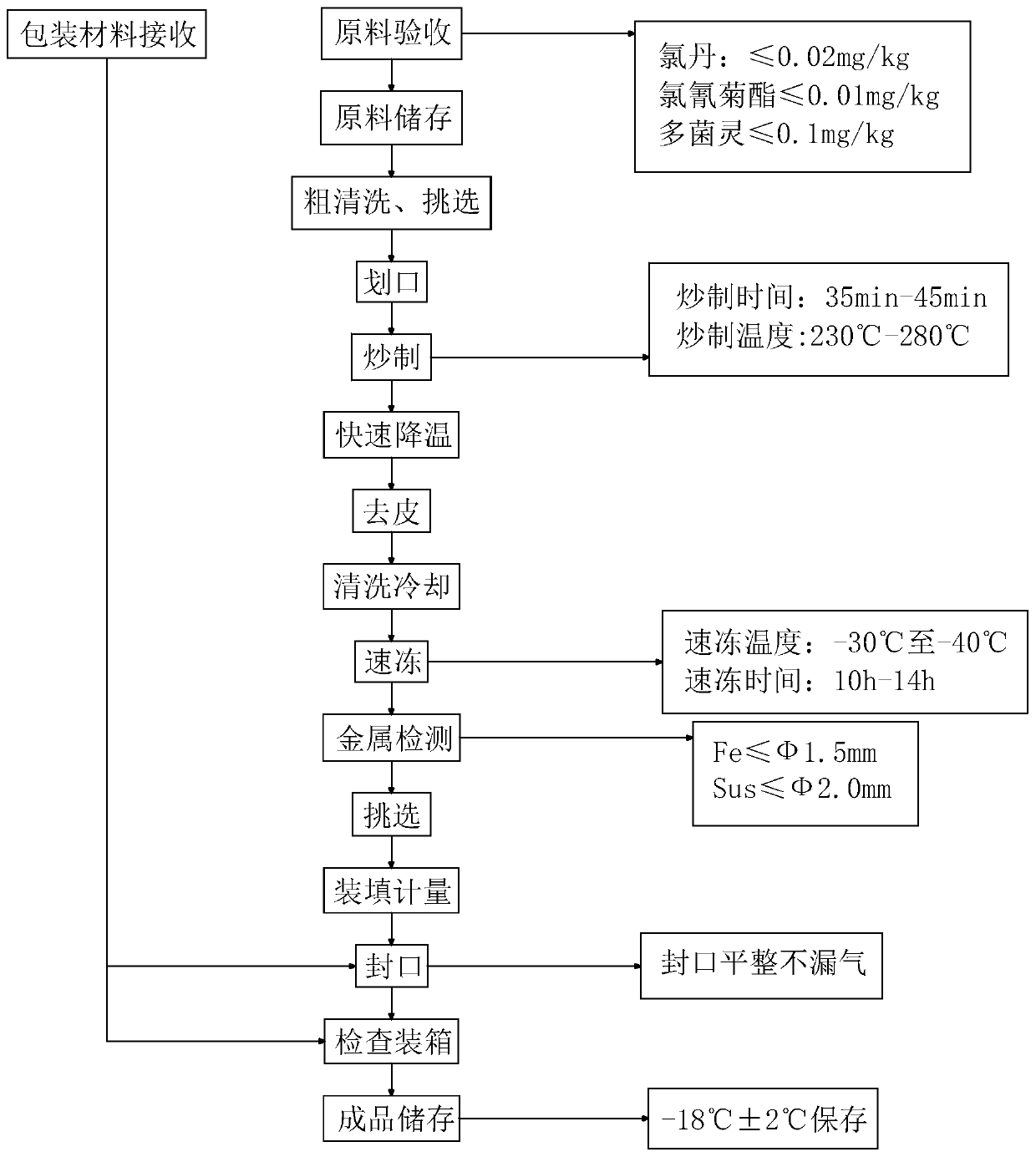

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] A kind of quick-frozen chestnut processing technology, comprises the steps:

[0031] Step 1: testing fresh chestnuts, the testing items are: chlordane, deltamethrin, beta-deltamethrin, and carbendazim. The required quality scores are as follows:

[0032] Chlordane: ≤0.02mg / kg, cypermethrin ≤0.01mg / kg, carbendazim ≤0.1mg / kg.

[0033] Step 2, putting the fresh chestnuts that pass the test into the cold storage for storage.

[0034] The temperature and humidity range of the cold storage environment is set at 0°C ± 2°C, and the humidity is ≥80%. The day before the chestnut raw materials are put into storage, the temperature of the cold storage should be set to -5°C, and the temperature of the cold storage should be monitored to prevent the chestnuts from becoming moldy and deteriorating due to excessive temperature.

[0035] Step 3: Take out the fresh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com