Rolling brush, floor brush, dust collector and cleaning method of particulate matter

A particle and rolling brush technology, which is applied to vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of poor user experience and difficulty in sucking particles into the ground brush, and achieve the effect of increasing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

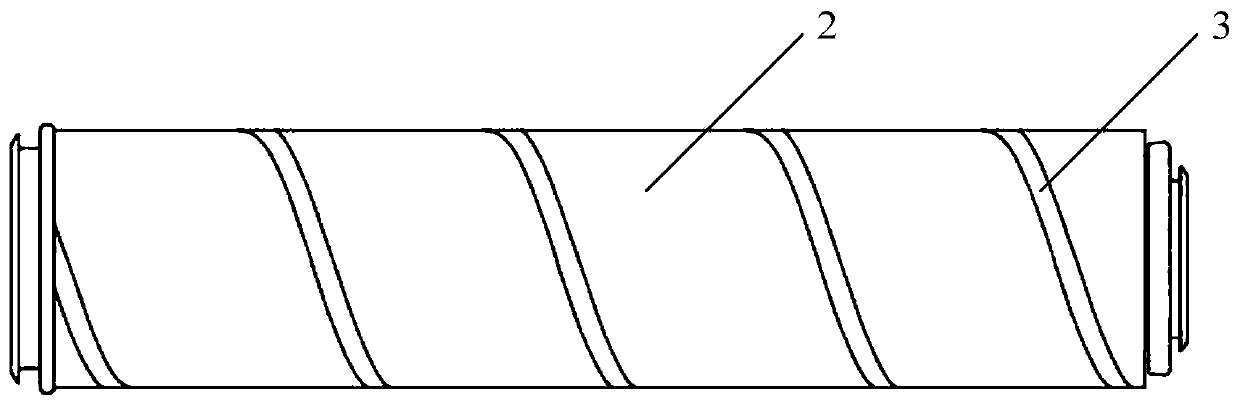

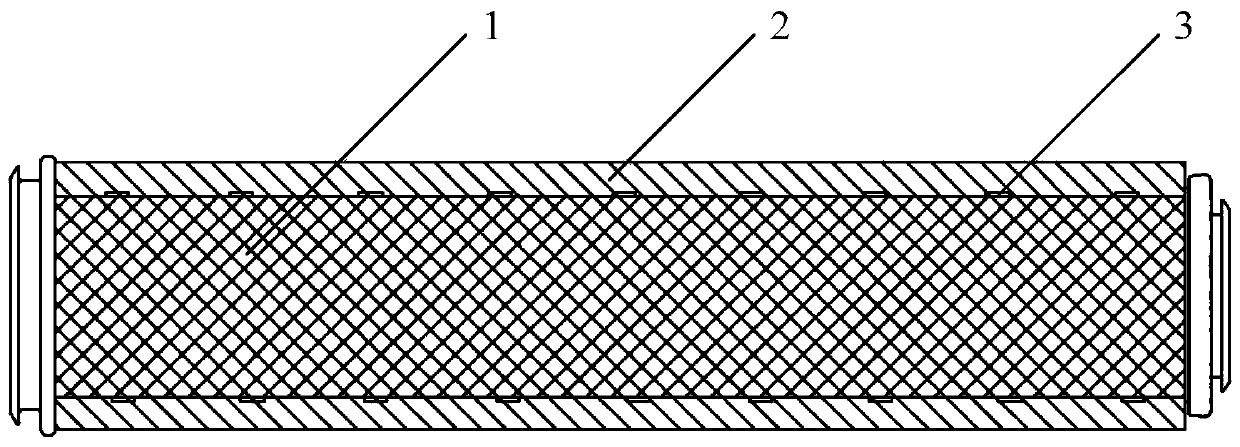

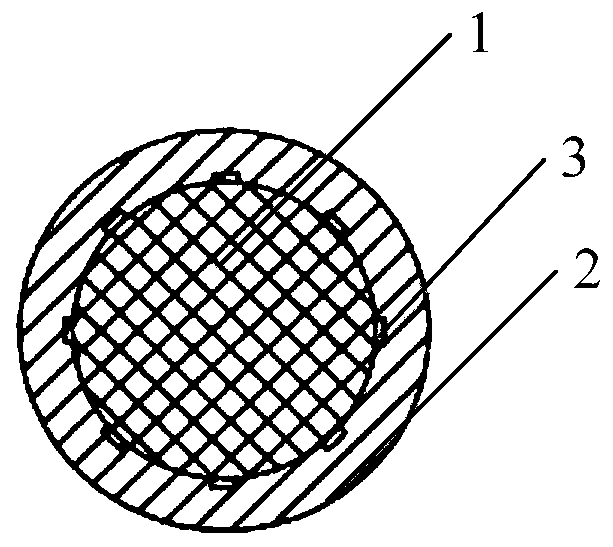

[0034] This embodiment provides a rolling brush, see Figure 1 to Figure 4 , including a shaft body 1 and a flocking layer 2 wrapped on its outer wall surface, at least one contact sensor 3 is arranged on the shaft body 1, and the height of the flocking layer 2 is greater than the contact sensor 3 relative to the outer wall surface of the shaft body 1 the height of.

[0035] It should be noted that no flocking layer 2 is provided on the part where the contact sensor 3 is provided on the outer wall of the shaft body 1 .

[0036] Compared with the prior art, the roller brush provided by this embodiment is provided with a contact sensor 3 on the shaft body 1 and inside the flocking layer 2. When there is only dust on the cleaning surface, the roller brush can pass the dust through the flocking layer 2. Take it to the suction port, and then enter the interior of the ground brush; when there are particles on the cleaning surface, the particles can pass through the flocking layer 2...

Embodiment 2

[0044] This embodiment provides a ground brush, see Figure 5 to Figure 7 , comprising ground brush main controller, rolling brush motor governor, rolling brush motor and the rolling brush 6 provided by embodiment one, contact sensor and rolling brush motor speed governor are respectively connected with ground brush main controller, rolling brush motor regulating The speed reducer is connected with the roller brush motor, and is used for adjusting the rotating speed of the roller brush motor.

[0045]When there is only dust on the cleaning surface, the roller brush 6 can bring the dust to the suction port through the flocking layer, and then enter the interior of the ground brush; when there are particles on the cleaning surface, the particles can pass through the flocking layer and contact the contact sensor. Make the contact sensor generate a particle signal and send it to the main controller of the ground brush. The main controller of the ground brush obtains the particle s...

Embodiment 3

[0054] This embodiment provides a vacuum cleaner, including the floor brush provided in Embodiment 2.

[0055] Compared with the prior art, the beneficial effects of the vacuum cleaner provided in this embodiment are basically the same as those of the ground brush provided in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com