Rapid feeding device for steel pipe machining

A technology of feeding device and steel pipe, applied in auxiliary devices, metal processing, metal processing equipment and other directions, can solve the problems of easy slippage, low feeding efficiency, difficult to promote, etc., and achieves low cost, high feeding efficiency, and easy promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

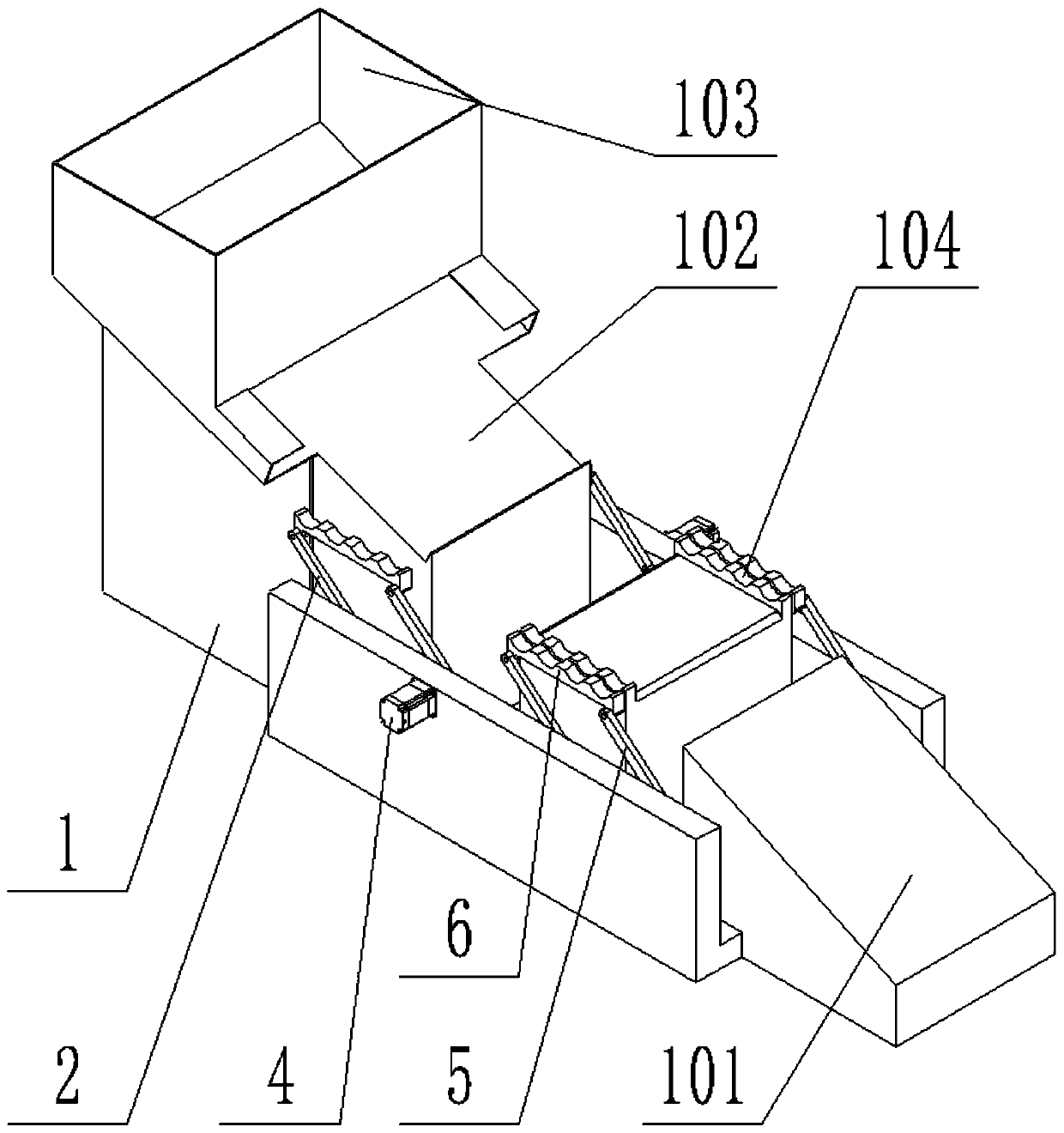

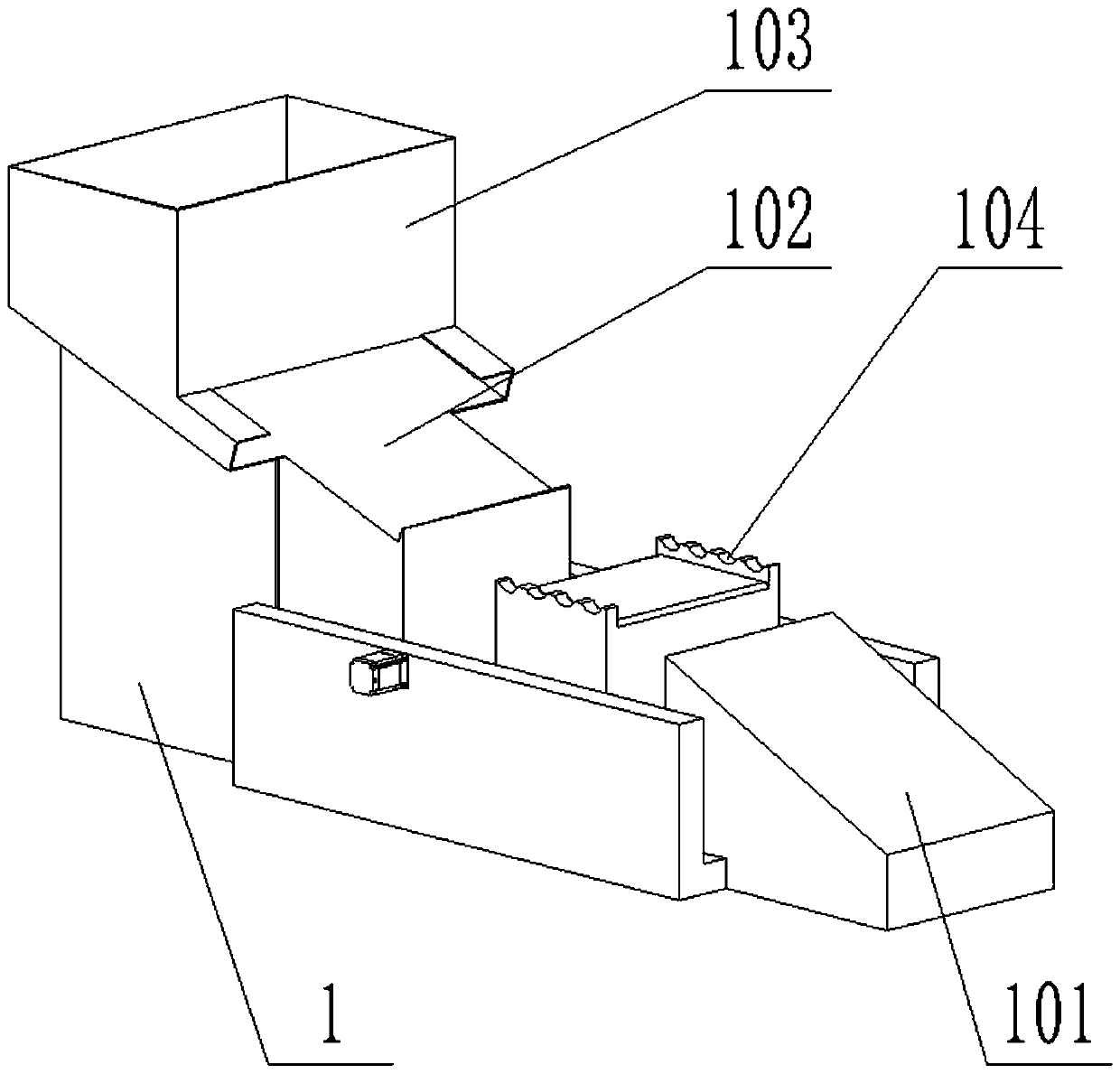

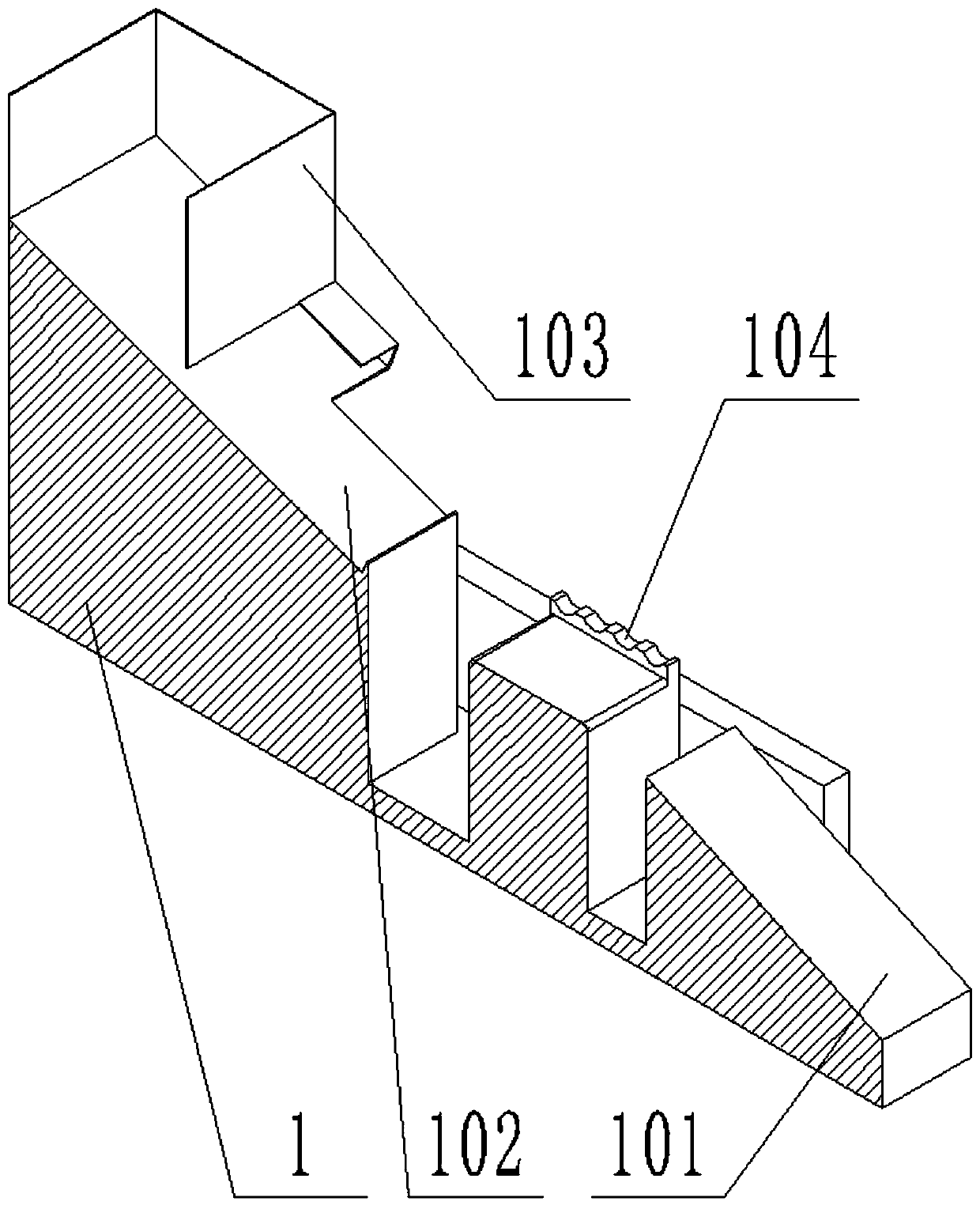

[0030] As attached figure 1 Attached Figure 8 Shown:

[0031] The present invention provides a fast feeding device for steel pipe processing, which includes: a support body 1, a feeding slope 101, a feeding slope 102, a storage box 103, a steel pipe fixing groove 104, a feeding connecting rod 2, a feeding block 3 , Feeding trough 301, motor 4, driving synchronous belt wheel 401, unloading connecting rod 5, driven belt wheel 501 and unloading block 6; the front and rear ends of the support body 1 are fixedly connected with a group of motors 4; the front and rear of the support body 1 There are two sets of feeding connecting rods 2 and two sets of unloading connecting rods 5 on the inner side of the end face respectively; the upper end faces of the two sets of feeding connecting rods 2 on the same side are hingedly connected to a set of feeding blocks 3; two sets on the same side A set of blanking blocks 6 are jointly hinged on the top of the blanking link 5; the rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com