Bearing outer ring press fitting locking mechanism for transmission shell

A transmission housing, bearing outer ring technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of reduced production efficiency, low strength of strong magnets, bearing outer ring falling off, etc., to achieve large effective contact area, The effect of prolonging service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

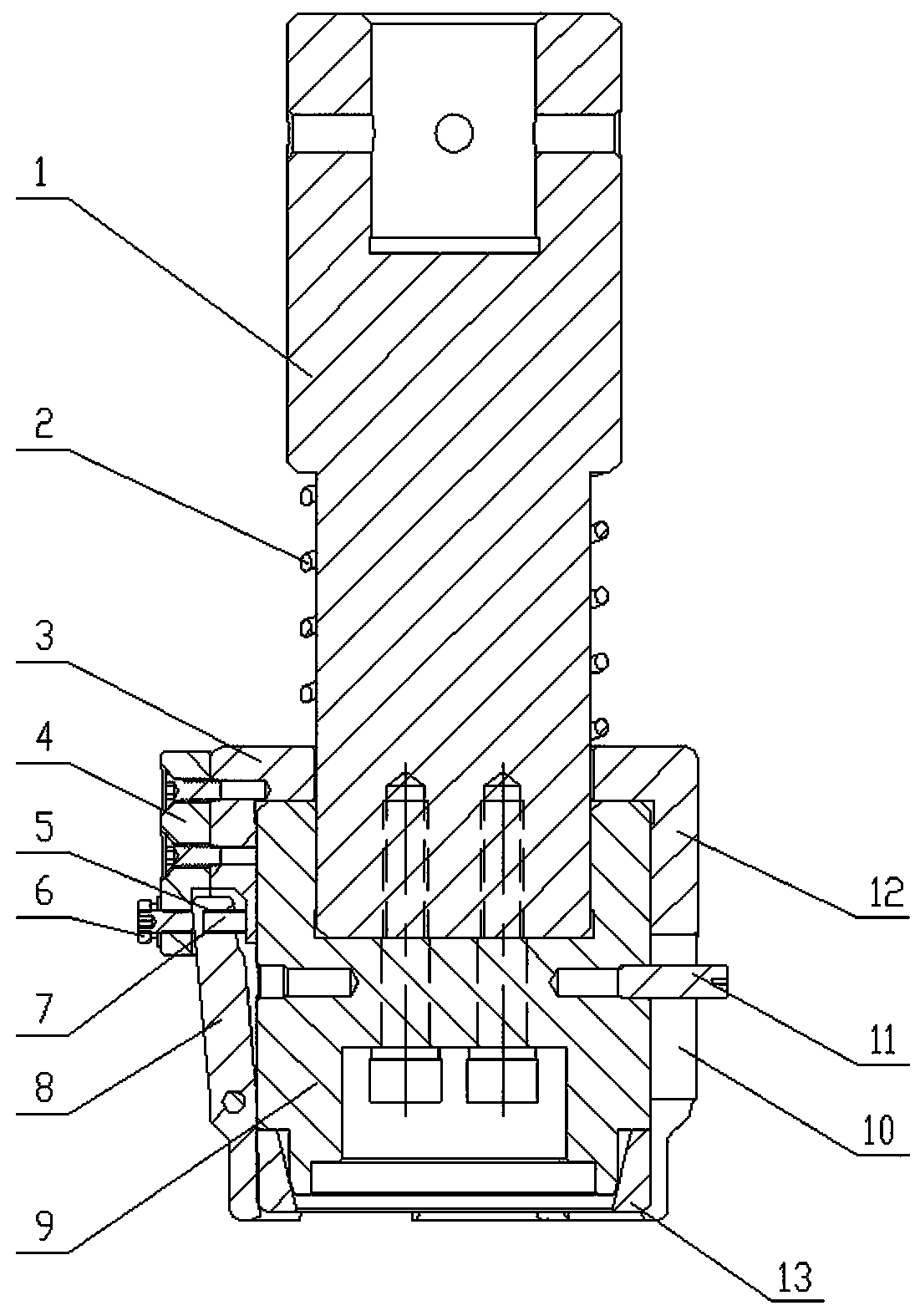

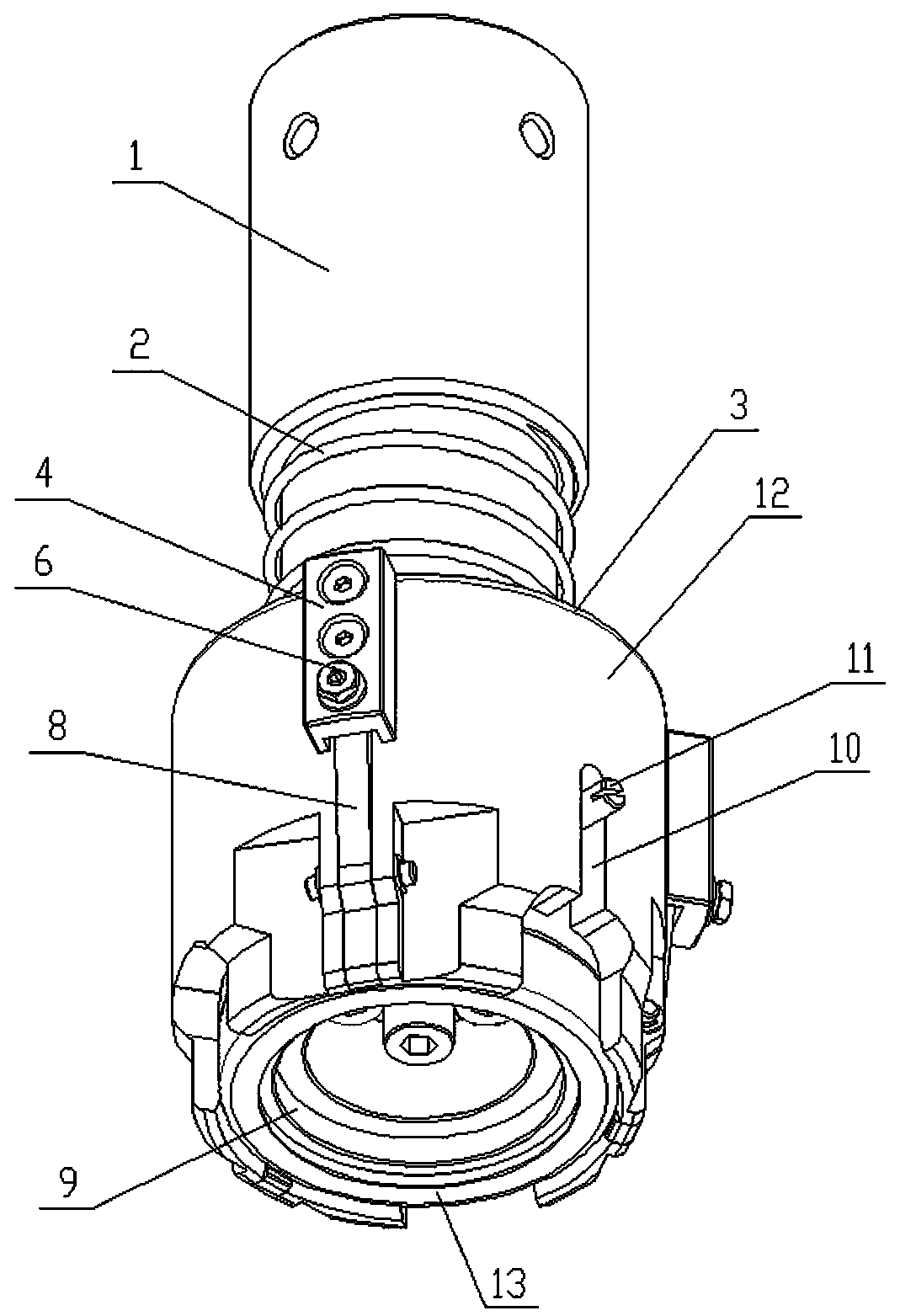

[0015] Such as figure 1 and figure 2 As shown, the transmission casing bearing outer ring press-fit locking mechanism of the present invention includes a vertically arranged pressure rod 1 , the outer diameter of the upper part of the pressure rod 1 is larger than that of other parts, thereby forming a step on the pressure rod 1 . The lower end of the pressing rod 1 is concentrically fixed with a columnar pressing head 9 , and the outer diameter of the pressing head 9 is larger than that of the lower end of the pressing rod 1 . The indenter 9 is covered with a sliding sleeve 12, and the sliding sleeve 12 and the indenter 9 are fitted in a sliding manner along the axial direction of the indenter 9. The upper end of the sliding sleeve 12 has an inwardly bent annular flange 3. The side 3 is located above the pressure head 9, and the inner diameter of the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com