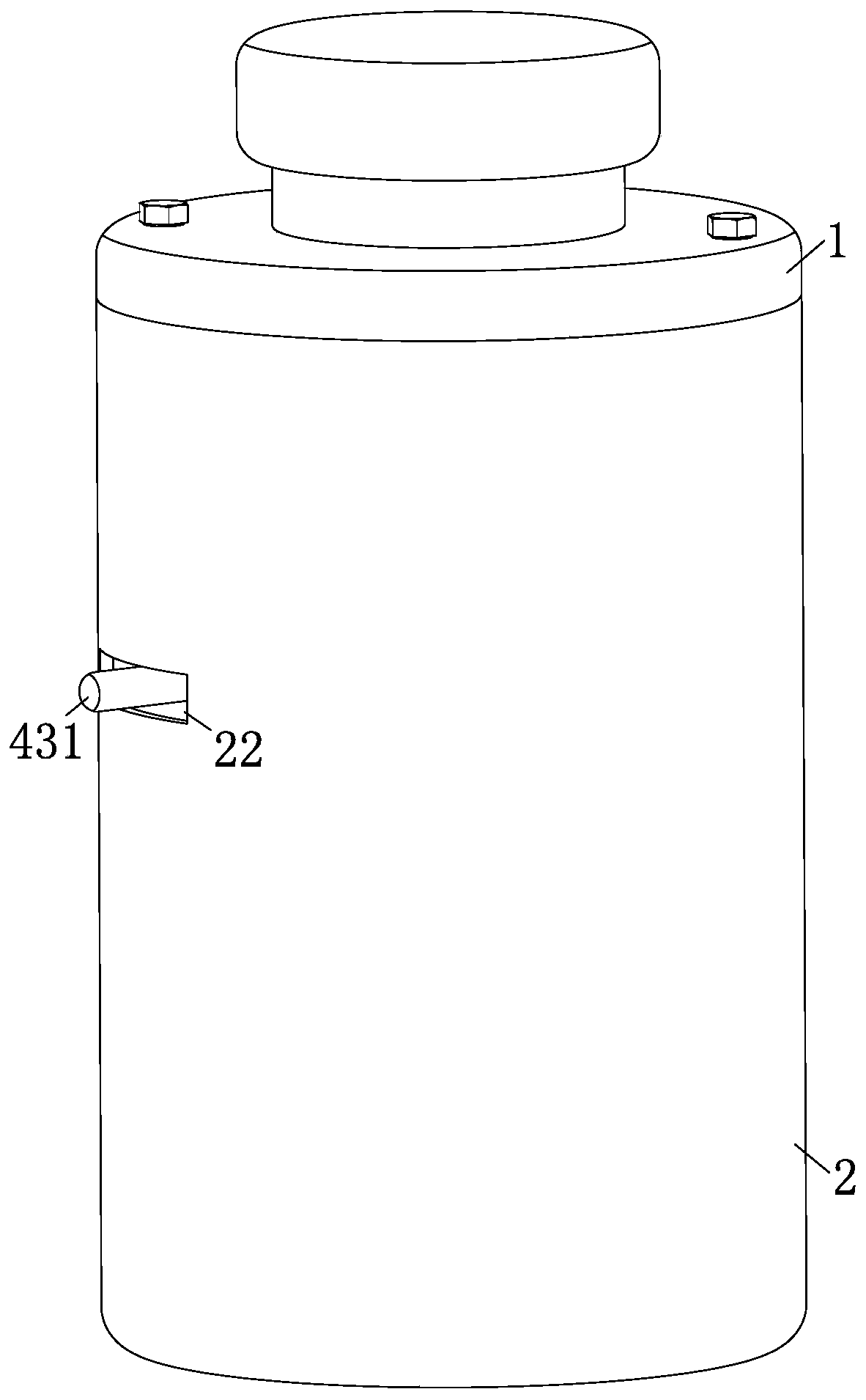

Alloy metal tank

A technology of metal cans and alloys, which is applied in the field of alloy metal cans, can solve the problems of metal cans storage effects, food taste and quality, and sticky pieces at the bottom of the cans are not easy to clean and remove, so as to achieve easy cleaning, improved structure, and storage good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

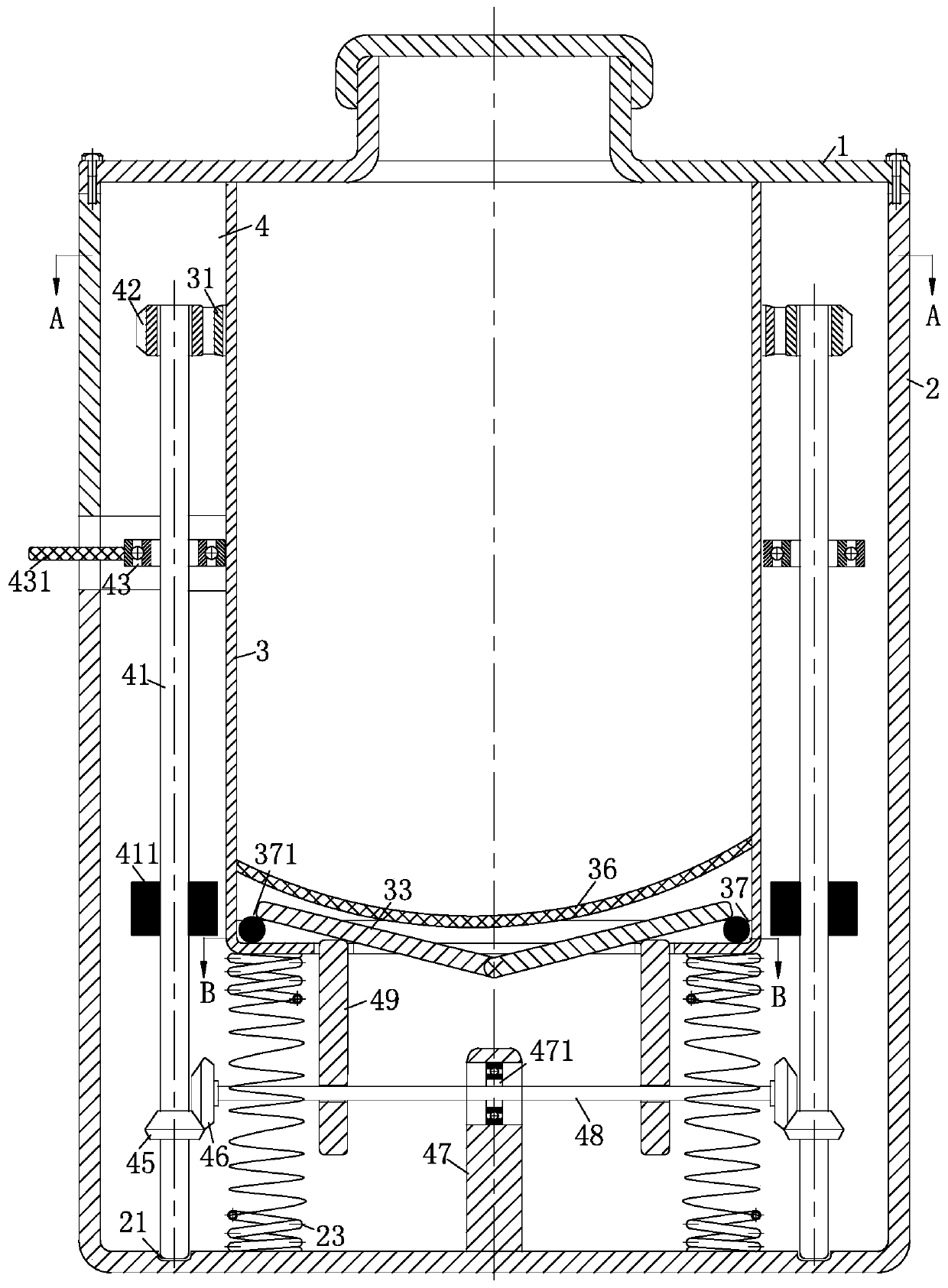

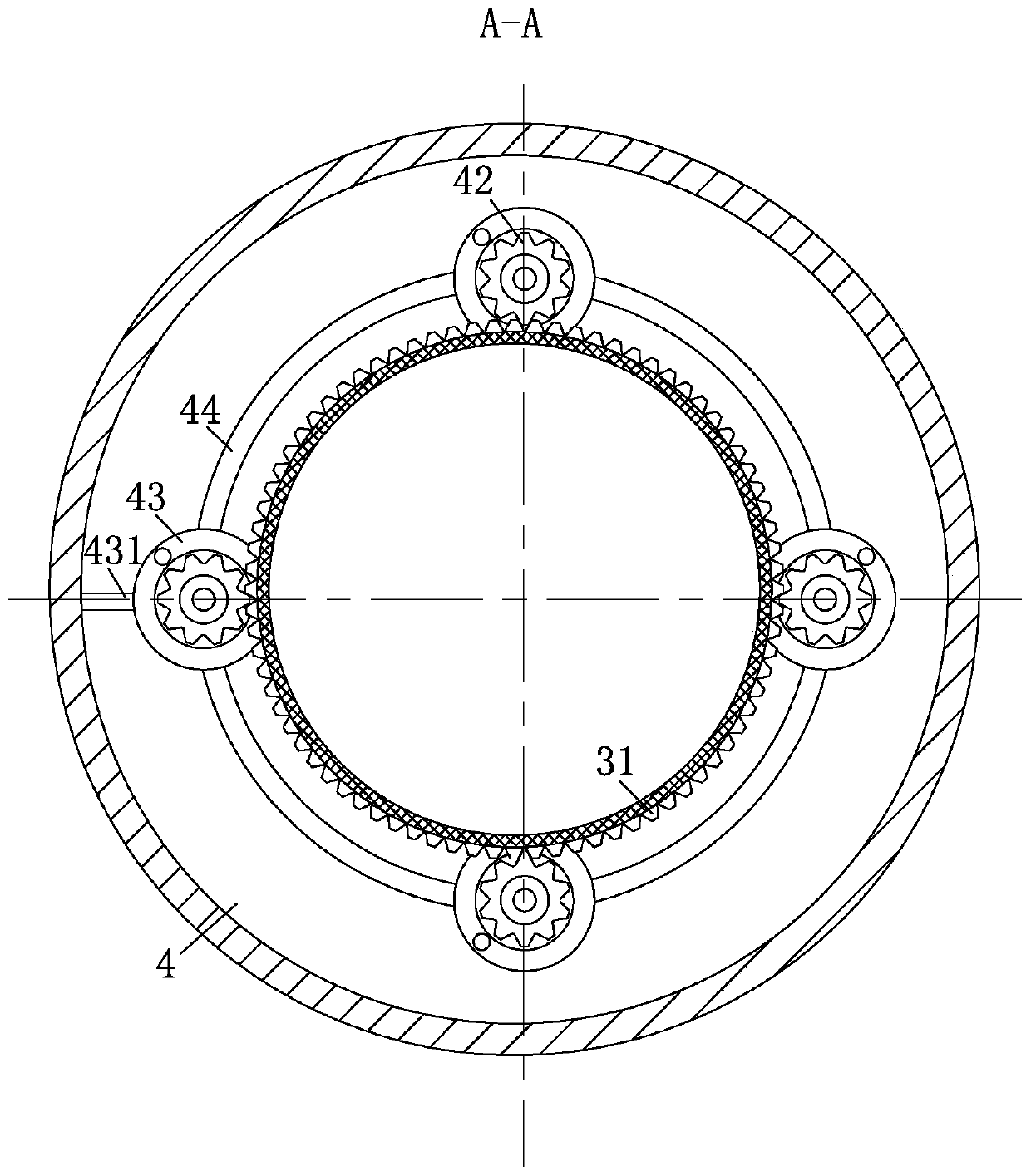

[0027] As an embodiment of the present invention, the outer surface of the cutting blade 33 is coated with Teflon coating, the edge of the cutting blade 33 is set as two symmetrical petals, the middle part of the cutting blade 33 is provided with a gap 331, and the bottom of the gap 331 Connected with a spring 332, the upper end of the spring is connected with a movable knife edge 333; during work, when the cutting blade 33 is pushed upward by the cam 49, the pressure of the adhesive block makes the top of the movable knife edge 333 be compressed, and when the adhesive block is gradually cut When opening, the residue of the sticky block falls, the pressure on the top of the movable knife edge 333 decreases gradually, and the bottom of the movable knife edge 333 is rebounded by the thrust of the spring 332, which accelerates the cutting speed of the cutting blade 33 to the sticky piece, and the movable knife edge 333 of the rebound can also Bounce off the residue remaining on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap