Integrated online cutting platform for automotive glass production line

An automotive glass and cutting platform technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reducing use efficiency, complex adjustment of cutting heads, inability to adjust cutting errors, etc., and achieves low processing costs and equipment. Beautiful appearance, simple and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

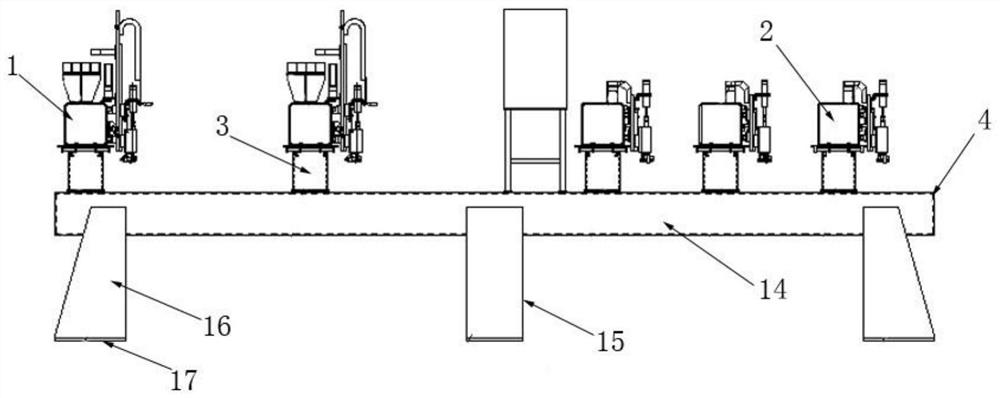

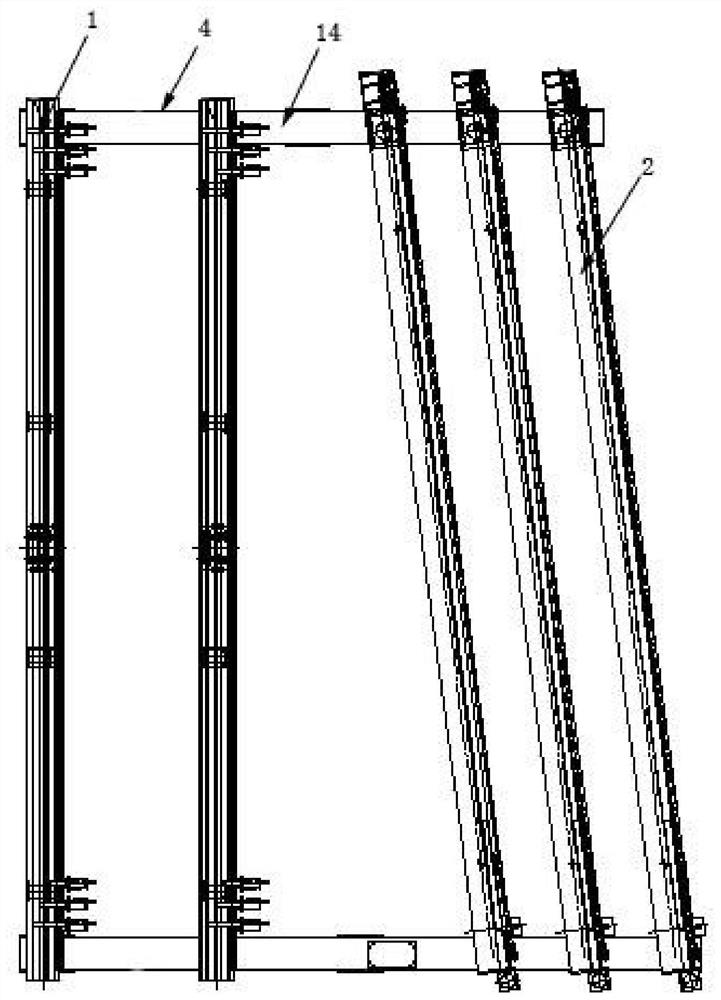

[0048] In further embodiments of the present invention, please continue to refer to figure 1 As shown, the platform 4 includes: two large girders 14 and several legs 15, the two ends of several longitudinal cutting bridges 1 are fixedly connected with the upper side of the two large girders 14 through the adjustment base 3 respectively, and the two ends of several transverse cutting bridges 2 are respectively passed through The adjustment base 3 is fixedly connected to the upper side of the two large beams 14, and several supporting legs 15 are fixedly connected to the lower sides of the two large beams 14 respectively.

[0049] In a further embodiment of the present invention, each leg 15 includes: two vertical plates 16 and a horizontal bottom plate 17, the upper ends of the two vertical plates 16 are fixedly connected to the two sides of the corresponding beam 14, and the two sides of the horizontal bottom plate 17 It is fixedly connected with the lower ends of the two vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com