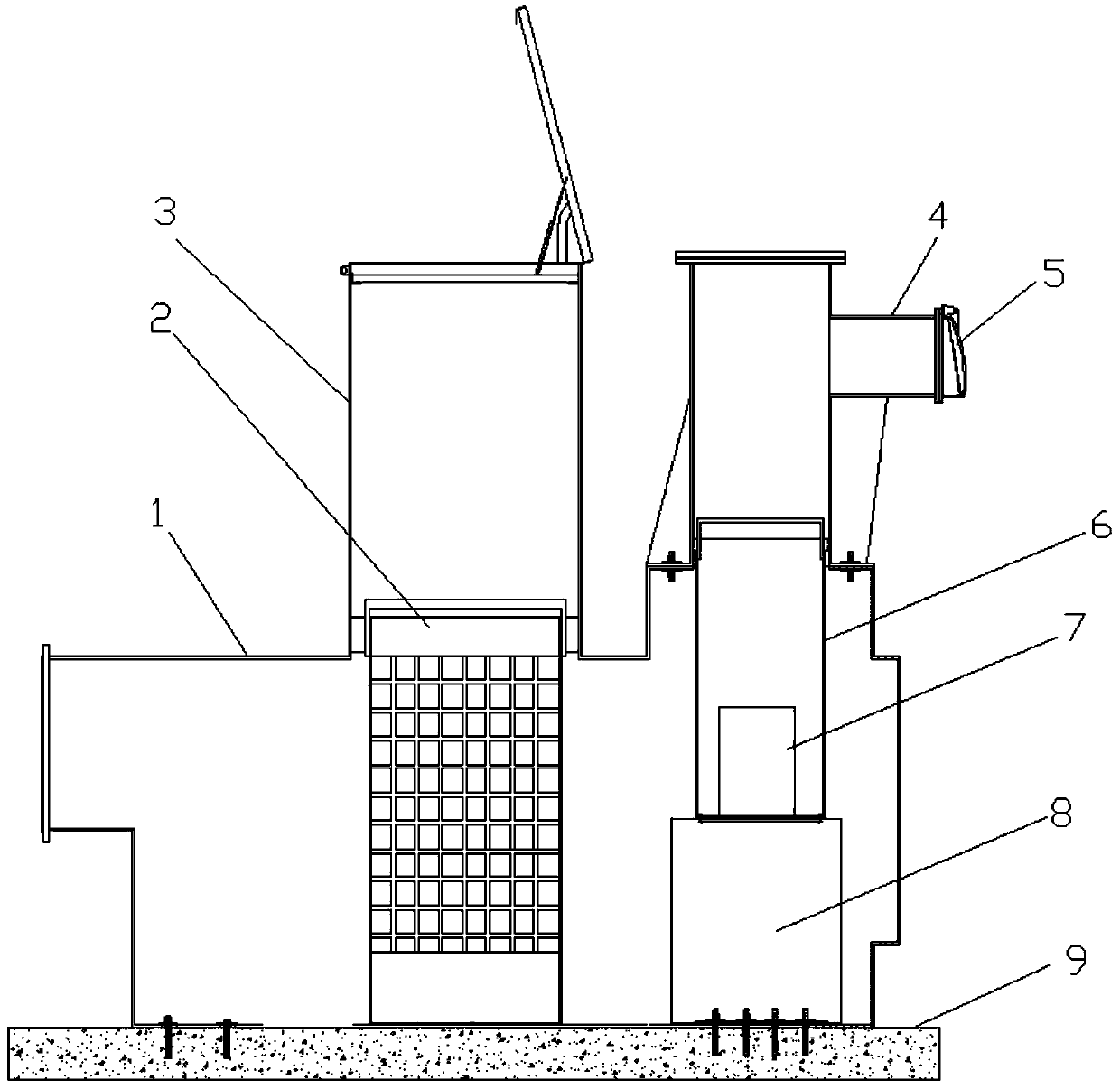

Integrated horizontal axial flow pump station and application thereof

A technology of axial flow pump and axial flow, which is applied in pumping stations, buildings, water supply devices, etc., can solve the problems of long construction period, shortened service life of pumping stations, and high failure of components, so as to reduce construction cost and maintenance cost, Reduced operating costs and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The application will be further introduced below in conjunction with embodiments.

[0025] In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, in the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Different embodiments can be substituted or combined. For those of ordinary skill in the art, other implementation manners can be obtained based on these embodiments without creative work.

[0026] In order to reduce the construction and maintenance cost of the pumping station, and at the same time extend the service life of the pumping station, the applicant has made extensive research and improved the existing pumping station. Firstly, it explored and developed a FRP integrated axial flow pumping station. The vertical glass fiber reinforced plastic wellbore is used as the suction well of the pump, and then a concrete forepool is set at the inlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com