Noise test method using train scale model device for aerodynamic noise wind tunnel test

A scale model and wind tunnel test technology, applied in the field of noise test, can solve the problem of the proportion of noise components that cannot be obtained separately from the position of the bogie and its wheelset, the high cost, and the inability to obtain the pantograph and its current diversion separately The proportion of the noise component of the cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

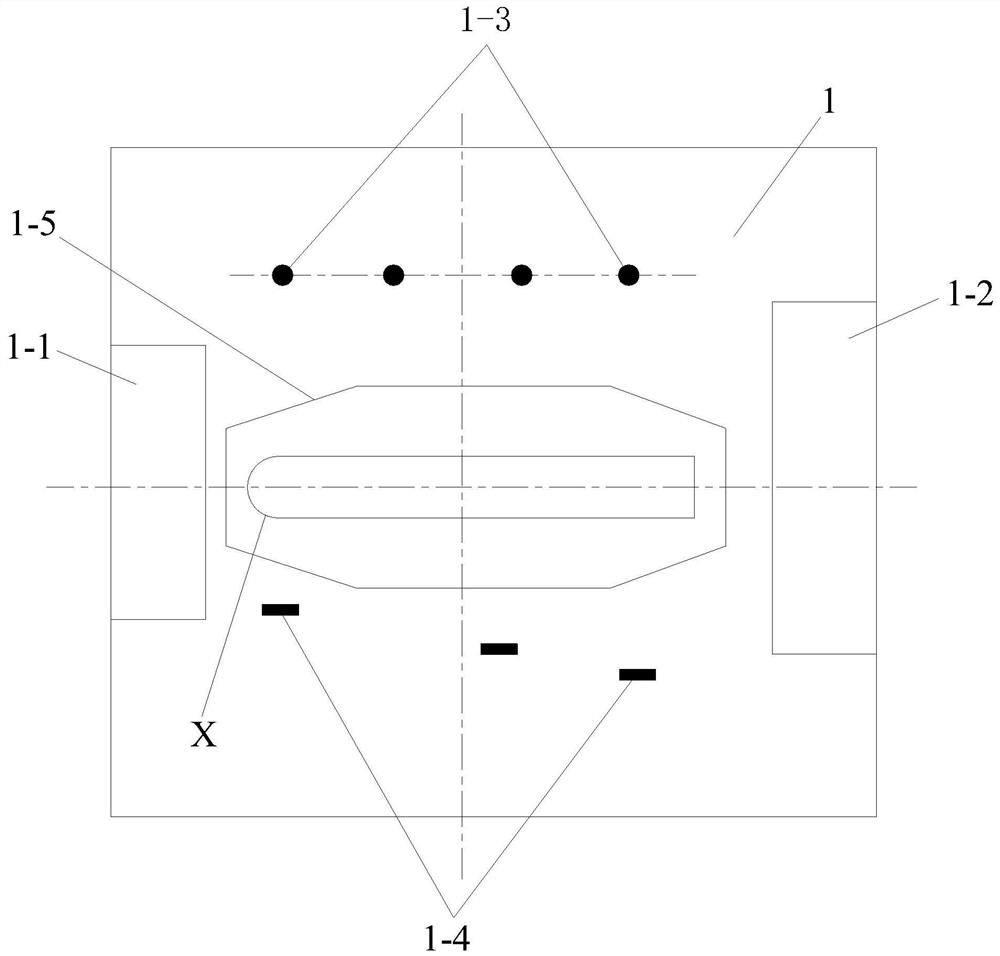

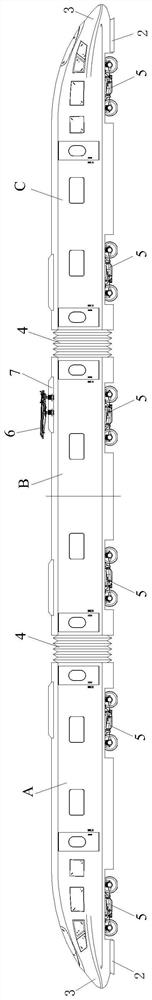

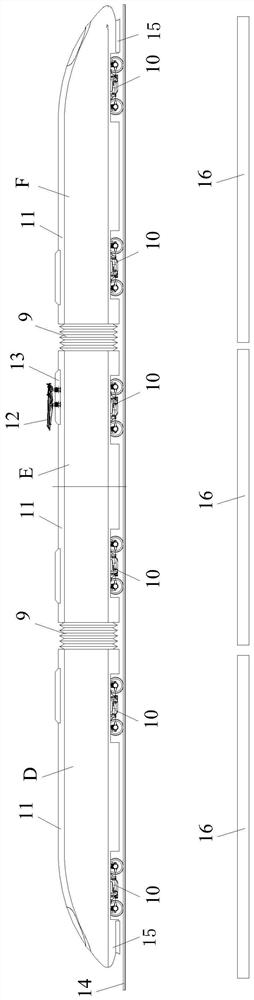

[0044] Such as Figure 3 to Figure 13 As shown, the train scale model device for aerodynamic noise wind tunnel test of the present invention includes a fully enclosed base 16 at the lower end of the detachable scale car body, a scale model car body with a scale obstacle remover and without a bogie 11. A plurality of reduced-scale through channel connecting parts 9, a reduced-scale track 14, a reduced-scale pantograph 12, a reduced-scale pantograph shroud 13, a plurality of reduced-scale bogies and their reduced-scale wheel pairs 10; Both the scale pantograph 12 and the scale pantograph shroud 13 are fixedly connected to the top of the middle section of the scale model car body in a detachable manner; the scale model car body 11 includes a scale head car D, a scale For the mid-size car E and the reduced-scale tail car F, the bottoms of both ends of the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com