Manufacturing method of heat-insulating decorative board

A technology for thermal insulation decorative panels and thermal insulation layers, applied in covering/lining, construction, building construction, etc., can solve the problems of high thermal conductivity and poor environmental performance, and achieve high waterproof and crack resistance, fast construction methods, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

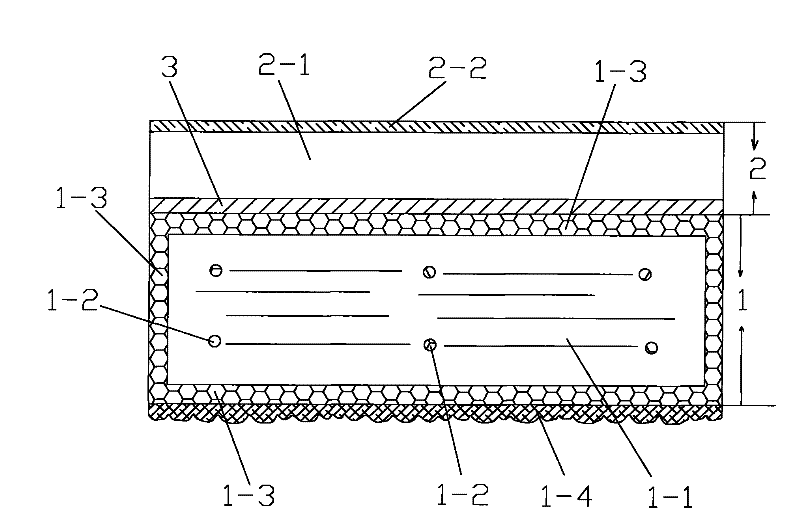

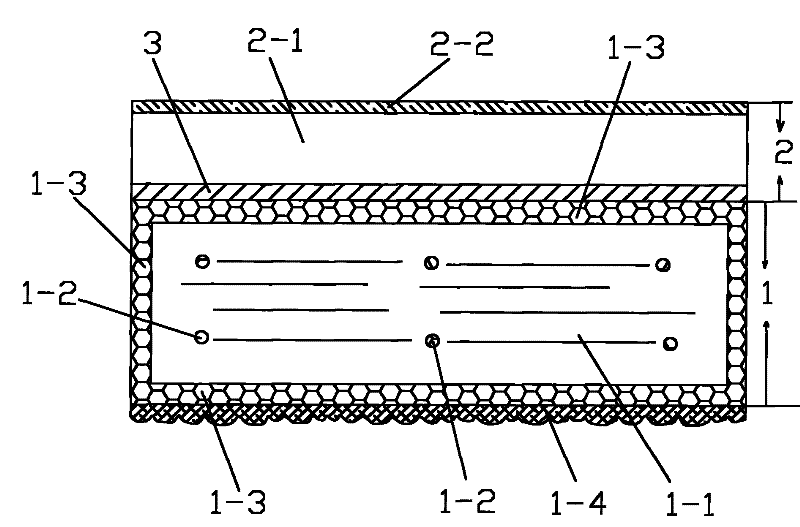

[0028] The novel ultra-thin thermal insulation decorative panel of the present invention consists of two parts, such as figure 1 As shown, the outer layer is a decorative protective layer 2; the inner layer is a vacuum insulation layer 1. The structure of the inner vacuum insulation layer 1 according to the present invention is as follows: evenly distributed slots 1-2 are arranged on the upper and lower sides of the ultrafine glass fiber plate 1-1, and the suction air is placed in the slots 1-2. The core material encapsulation layer is arranged outside the core material, the air barrier layer 1-3 is wrapped outside the core material encapsulation layer, the protective layer is outside the air barrier layer 1-3, the decorative layer 2-2 is outside the protective layer, and the getter It is used to absorb the residual gas after the exhaust in the plate and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com