Potting method applied to electronic equipment for dairy cows

An electronic equipment, potting technology, applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, sealed casing, etc., can solve problems such as reducing equipment service life, electronic equipment corrosion, equipment damage, etc., to reduce interference and corrosion. effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

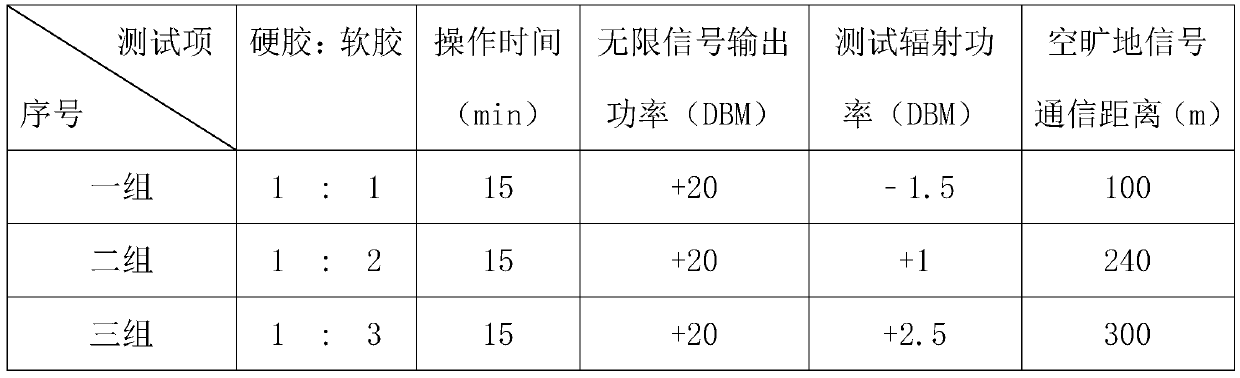

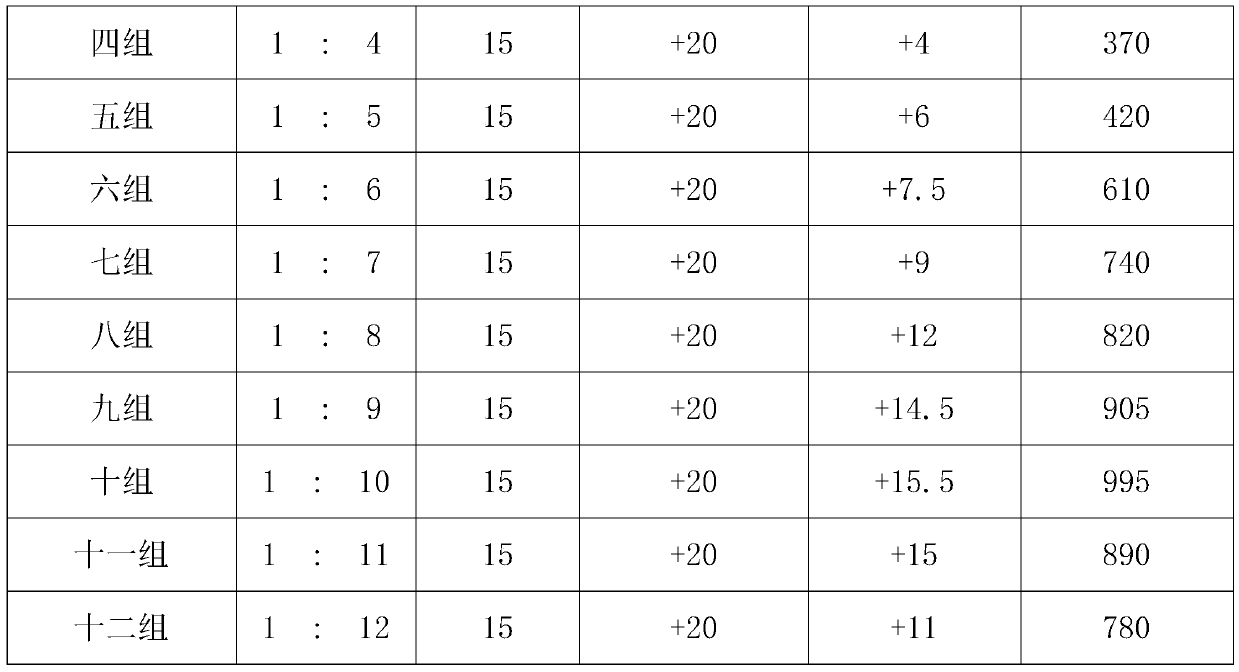

[0024] Embodiment 1: a kind of potting method applied to dairy cow electronic equipment, is characterized in that, comprises the following steps:

[0025] Step 1: Preparation of soft glue: Put the two components of black fluid potting silica gel and white fluid silica gel curing agent into the container according to the mass ratio of 1:1 for full mixing, and use the mixer to stir fully in a clockwise direction 10 minutes, after the two components are fully mixed, let stand at room temperature for 30 minutes to form a mixed fluid soft gel;

[0026] Step 2: Add soft rubber catalyst with 1.5% soft rubber mass to the fluid soft rubber, use a mixer to fully stir clockwise for 5 minutes, and let stand at room temperature for 10 minutes;

[0027] Step 3: Put the components to be packaged into the housing of the electronic product, keep the surface of the base material in the housing clean and dry, and fill the mixed fluid soft glue into the housing, so that the circuit board is compl...

Embodiment 2

[0037] Embodiment 2: a kind of potting method applied to dairy cow electronic equipment, it is characterized in that, comprises the following steps:

[0038] Step 1: Preparation of soft glue: Put the two components of black fluid potting silica gel and white fluid silica gel curing agent into the container according to the mass ratio of 1:1 for full mixing, and use the mixer to stir fully in a clockwise direction 13 minutes, after the two components are fully mixed, let stand at room temperature for 30 minutes to form a mixed fluid soft gel;

[0039] Step 2: Add soft rubber catalyst with 1.5% soft rubber mass to the fluid soft rubber, use a mixer to fully stir clockwise for 8 minutes, and let stand at room temperature for 10 minutes;

[0040] Step 3: Put the components to be packaged into the housing of the electronic product, keep the surface of the base material in the housing clean and dry, and fill the mixed fluid soft glue into the housing, so that the circuit board is co...

Embodiment 3

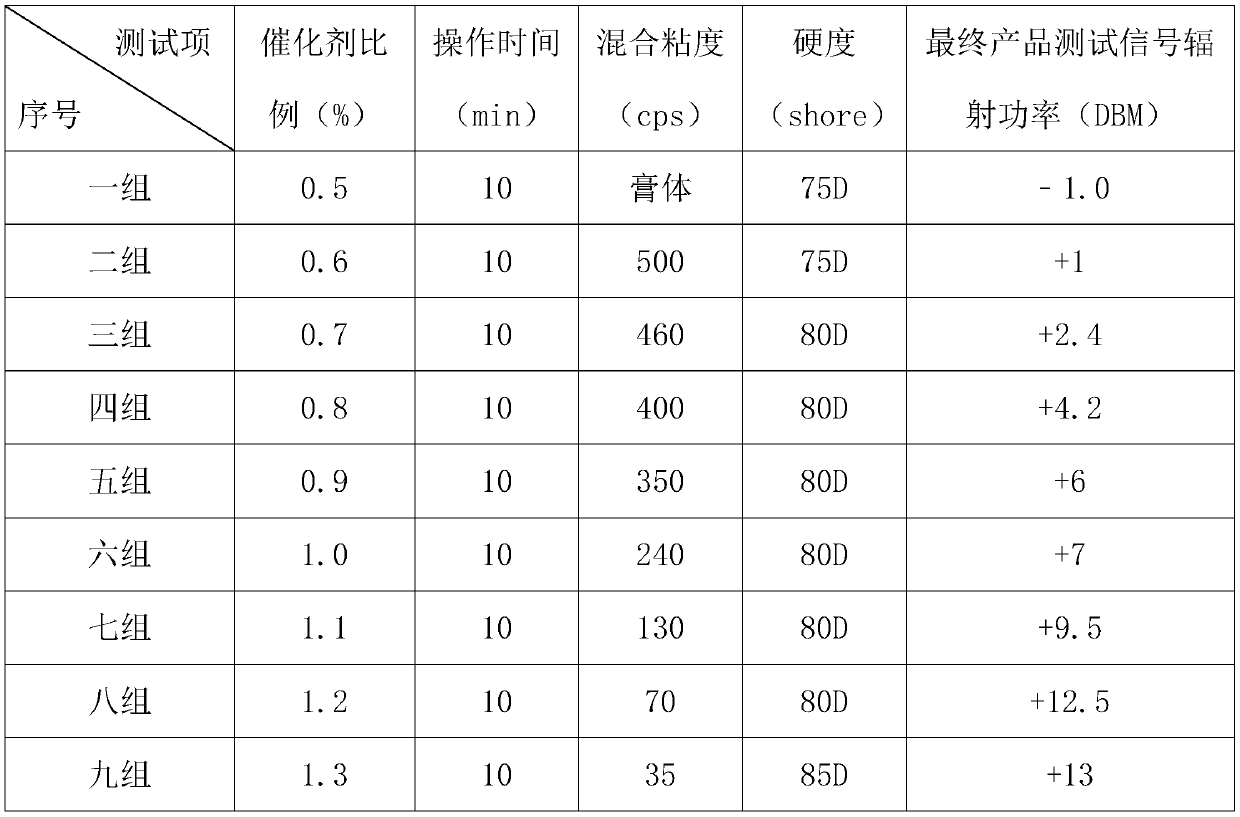

[0050] Embodiment 3: a kind of potting method applied to dairy cow electronic equipment, it is characterized in that, comprises the following steps:

[0051] Step 1: Preparation of soft glue: Put the two components of black fluid potting silica gel and white fluid silica gel curing agent into the container according to the mass ratio of 1:1 for full mixing, and use the mixer to stir fully in a clockwise direction 15 minutes, after the two components are fully mixed, let stand at room temperature for 30 minutes to form a mixed fluid soft gel;

[0052] Step 2: Add soft rubber catalyst with 1.5% of the soft rubber mass to the fluid soft rubber, use a mixer to fully stir clockwise for 10 minutes, and let stand at room temperature for 10 minutes;

[0053] Step 3: Put the components to be packaged into the housing of the electronic product, keep the surface of the base material in the housing clean and dry, and fill the mixed fluid soft glue into the housing, so that the circuit boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com