Core pack

A technology for cores and retaining elements, which is used in the field of casting molds and castings, and core groups. It can solve problems such as screw or cover leakage, and achieve the effect of gentle force introduction and uniform force introduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

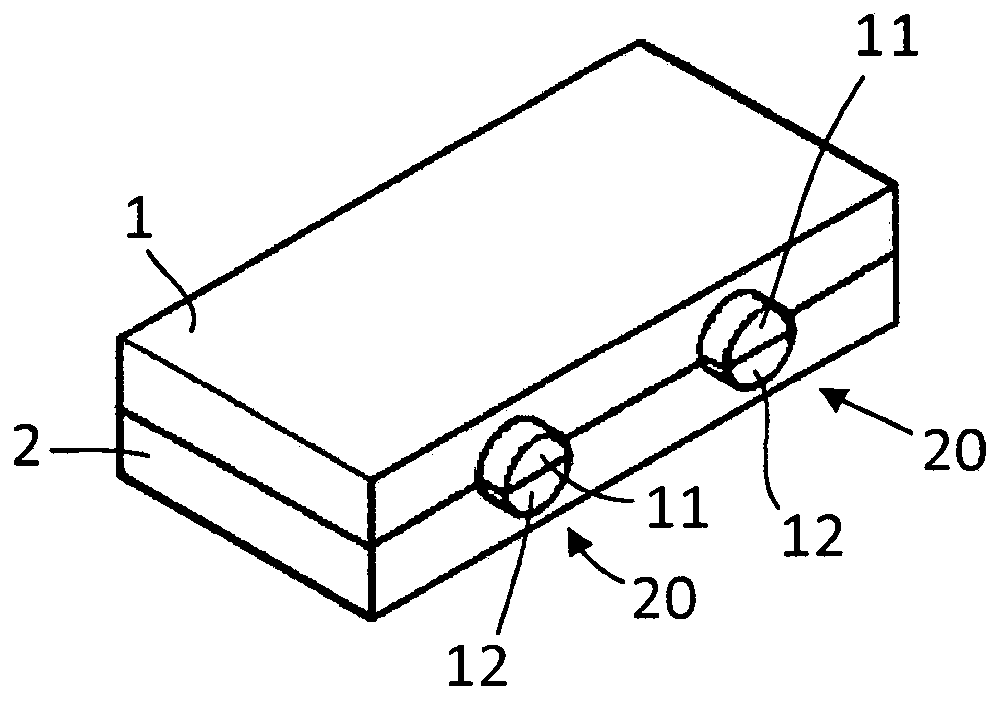

[0035] figure 1 A schematic perspective view of a core set is shown, comprising a core 1 and a core 2 , which form two retaining sections 11 and 12 , respectively. The retaining sections are oriented and positioned relative to one another in such a way that a setting section 20 is formed. The setting section is used to set the figure 1 Retaining elements not shown.

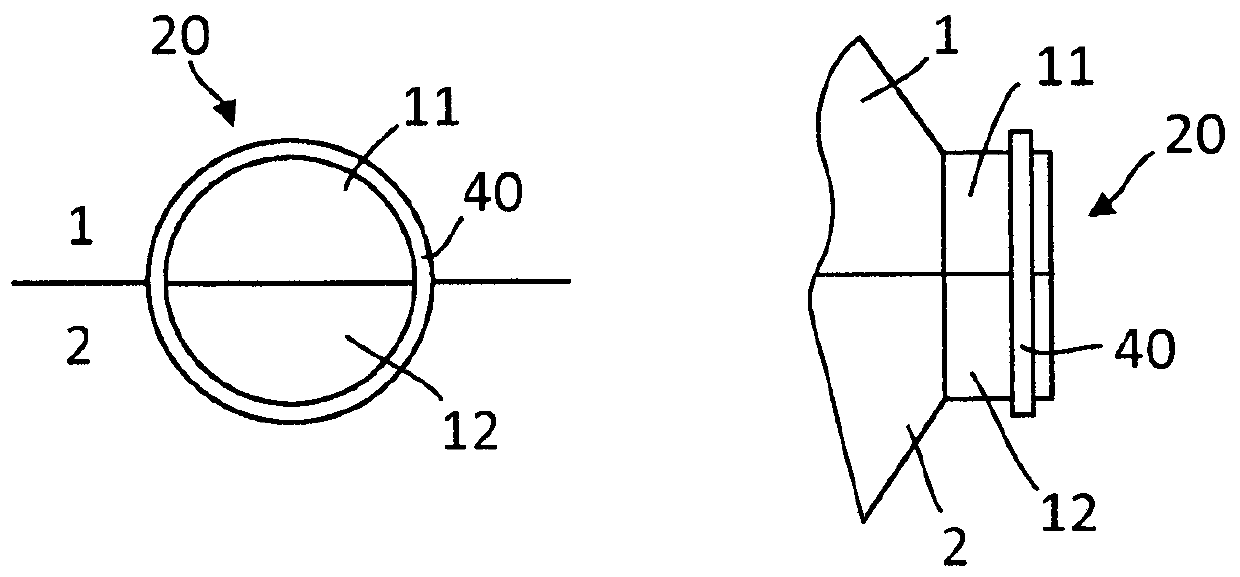

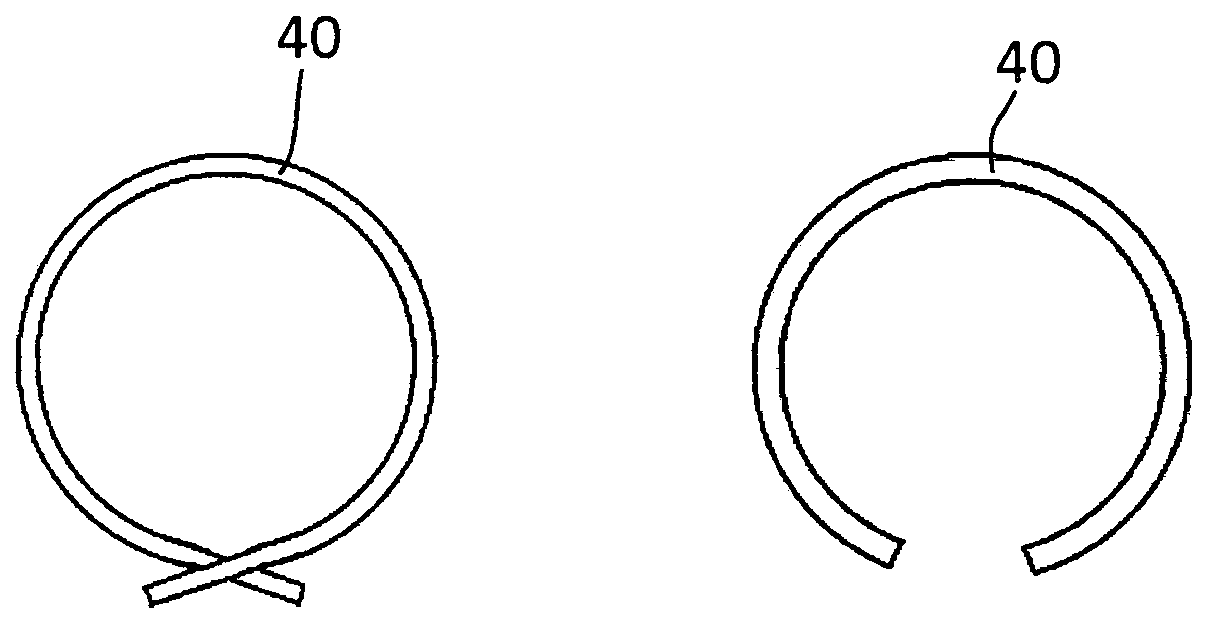

[0036] figure 2 In the left half of the figure, a front view of a setting section 20 is shown, which is formed from two holding sections 11 , 12 . An annular, in particular annular holding element 40 is arranged around the mounting section 20 . In the right half of the figure, which shows a side view, it can be seen how the holding element 40 surrounds the arrangement section 20 and thus fixes or presses the two cores 1 and 2 relative to each other. Depending on the configuration of the holding element 40 , in this state already a prestressing can be exerted on the two holding sections 11 and 12 or on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com