Cavity equipment for hexagonal shell casting products

A hexagonal, product technology, applied in casting and forming equipment, metal processing equipment, casting molds, etc., can solve problems such as affecting the use strength of products, inability to effectively discharge air bubbles, trachoma in the internal structure of blanks, etc., to ensure product quality. effect with quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

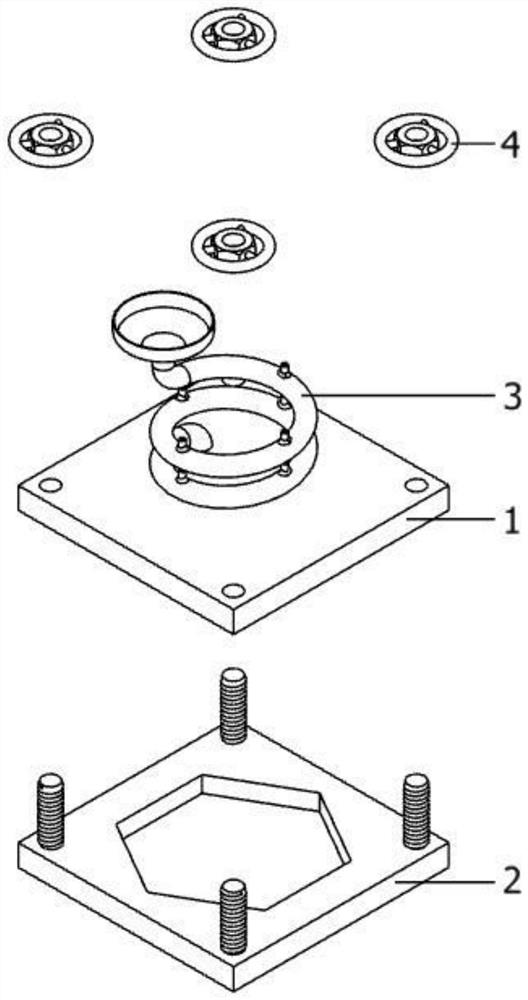

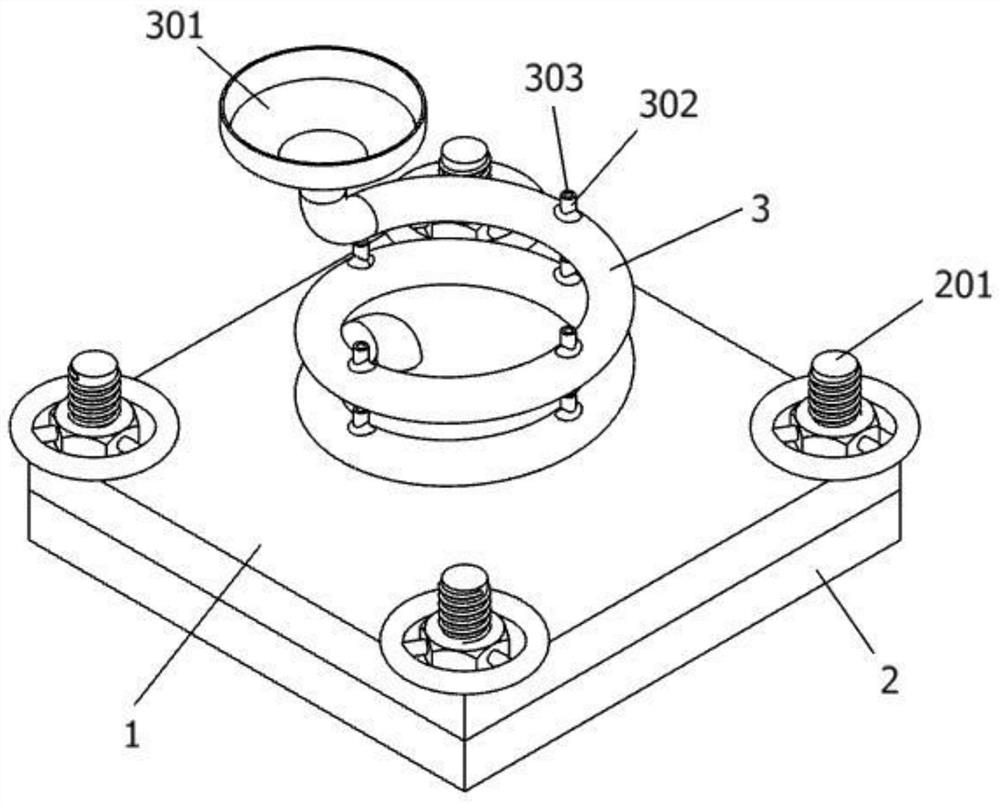

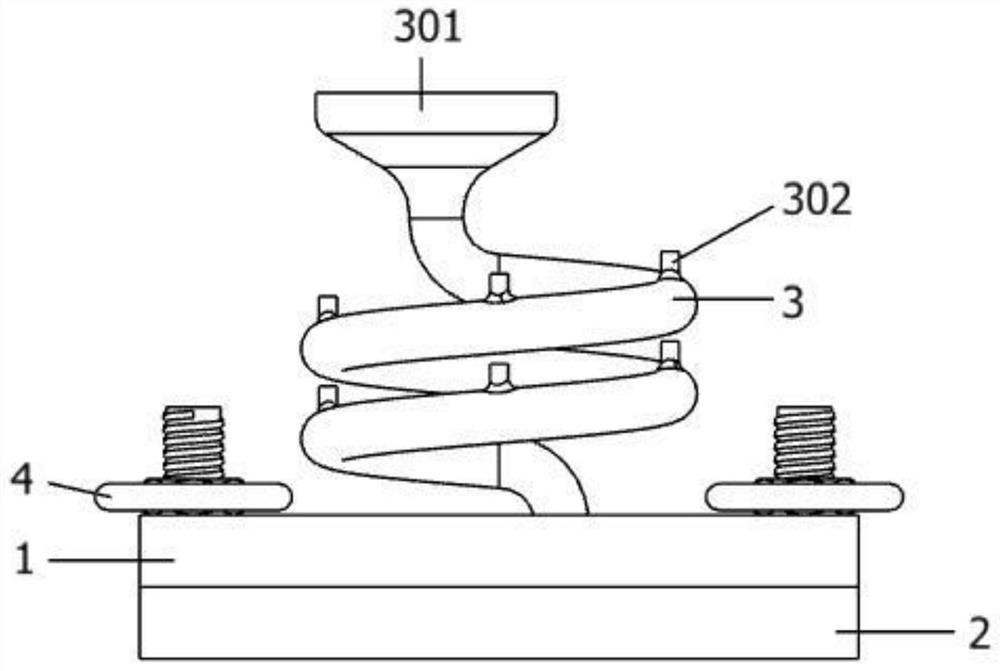

[0035] as attached figure 1 to attach Figure 12 Shown:

[0036] The present invention provides a cavity-shaped equipment for hexagonal shell casting products, including: an upper mold body 1, characterized in that: a lower mold body is fixedly installed directly below the upper mold body 1 through four sets of fastening mechanisms 4 2; A spiral tube 3 is arranged above the upper mold body 1 , and the tail of the spiral tube 3 is embedded inside the upper mold body 1 .

[0037] Wherein, the upper mold body 1 also includes a hexagonal punch 101 and a circular limiting through hole 102, a hexagonal punch 101 is arranged at the center of the bottom end surface of the upper mold body 1, and four edges of the upper mold body 1 top surface A circular limiting through hole 102 is opened at the included corners.

[0038] Wherein, the lower mold body 2 also includes a limit stud 201, a hexagonal die 202, a hexagonal die 202 is provided at the center of the top surface of the lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com