Welding accompanying tool of fish plate

A fishplate and tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high welding requirements, waste of manpower, and lower pass rate, so as to improve welding quality and pass rate, improve Welding work efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

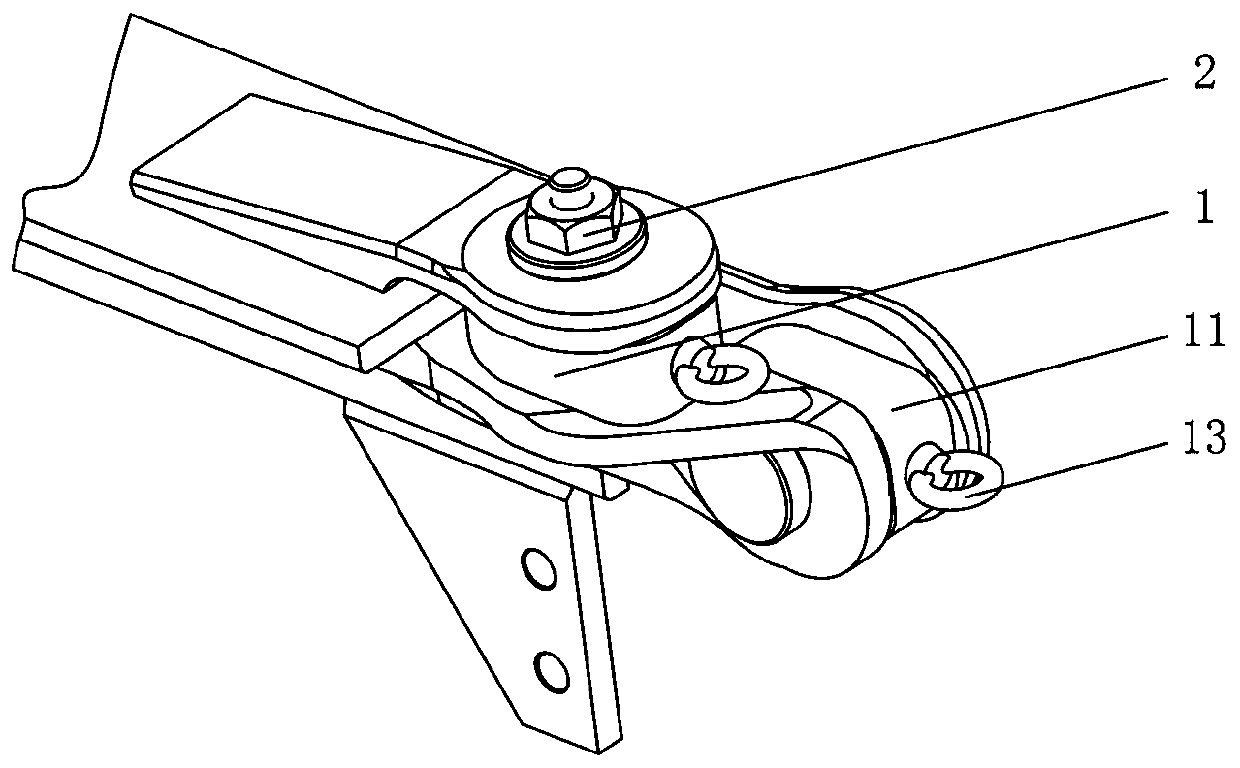

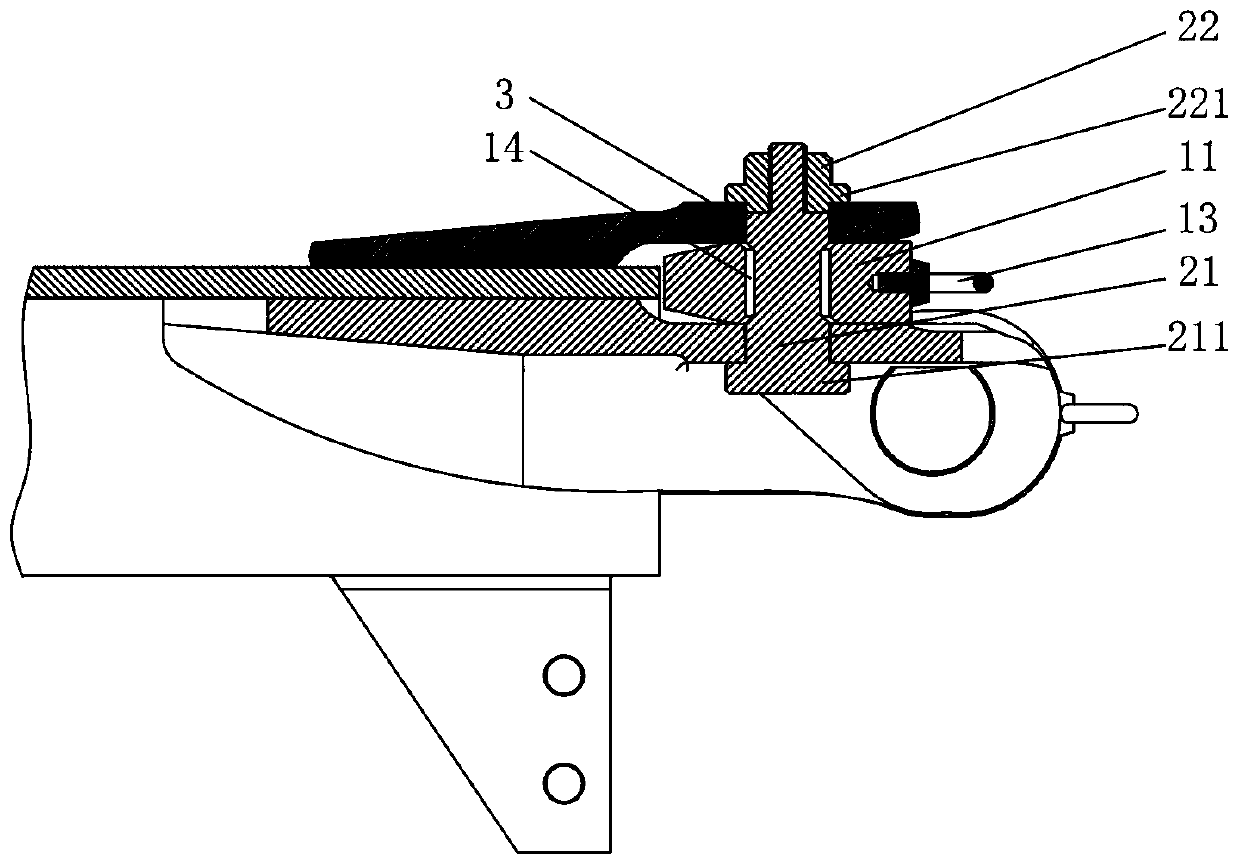

[0035] Such as figure 1 As shown, the fishplate welding accompanying tooling of this embodiment is used between the riveting station and the repair welding station of the fishplate automatic welding production line, and includes a distance fixing device 1 and a fixing device 1 for fixing the distance between the inner and outer fishplates. The coaxiality fixing device 2 of the coaxiality of the through hole 3 on the opposite inner and outer fishplates. When the fishplate parts arrive at the riveting welding station of the automatic welding production line, the positioning riveting welding is carried out first, and then the distance fixing device 1 and the coaxiality fixing device 2 are installed to completely fix the fishplate relative to the main limb, so that the fishtail The plate will not be shifted during the handling process from the riveting station to the welding station, from the welding station to the repairing station, and during the welding process, which improves ...

Embodiment 2

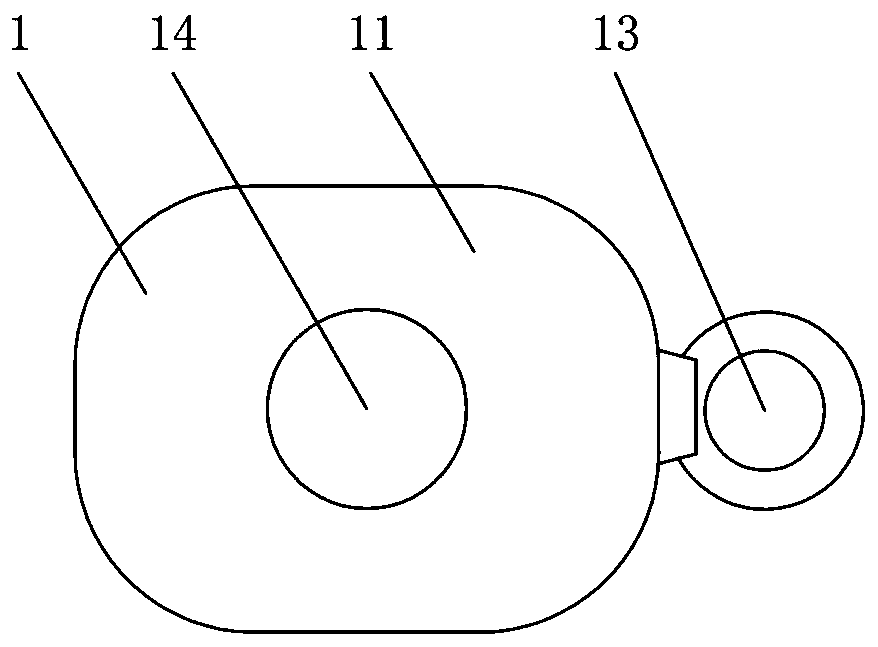

[0042] This embodiment is basically the same as Embodiment 1, the only difference is that, as Figure 4 As shown, the space-avoiding area 14 on the distance fixing device 1 of the present embodiment is a U-shaped through groove whose circular arc part corresponds to the position of the through hole 3 and whose diameter is not less than the diameter of the through hole 3. The U-shaped through groove is along the through hole. 3 Axially penetrate the spacing fixing device 1, the opening of which faces the fixed end of the fishplate. The distance fixing device 1 with such an avoidance area 14 can be installed before the coaxiality fixing device 2 and then removed after the coaxiality fixing device 2, or can be installed after the coaxiality fixing device 2 and preceded by the coaxiality fixing device 2. The axiality fixing device 2 is removed, and the assembly and disassembly process is more random, which expands the scope of application. In other embodiments, it is also possibl...

Embodiment 3

[0044] This embodiment is basically the same as Embodiment 1 and Embodiment 2, the only difference is that, as Figure 5 As shown, the coaxiality fixing device 2 of this embodiment is a taper pin, wherein: the shaft body 21 is provided with a tapered shaft section located inside the first blocking step 211 and corresponding to the position of the fishplate on one side, and the end The sleeve 22 is provided with a tapered shaft section located inside the second blocking step 221 and corresponding to the fishplate on the other side. When the end sleeve 22 is fastened to the external threaded end, the tapered shaft section can automatically center the inner and outer fishplates, and is more convenient for disassembly and assembly, further improving the fixing effect and disassembly efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com