Steel plate hoisting clamp for steel structure assembling

A steel structure and steel plate technology, applied in the field of steel plate hoisting fixtures, can solve problems such as increased equipment costs, achieve the effects of enhancing structural strength and compression resistance, increasing clamping force, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

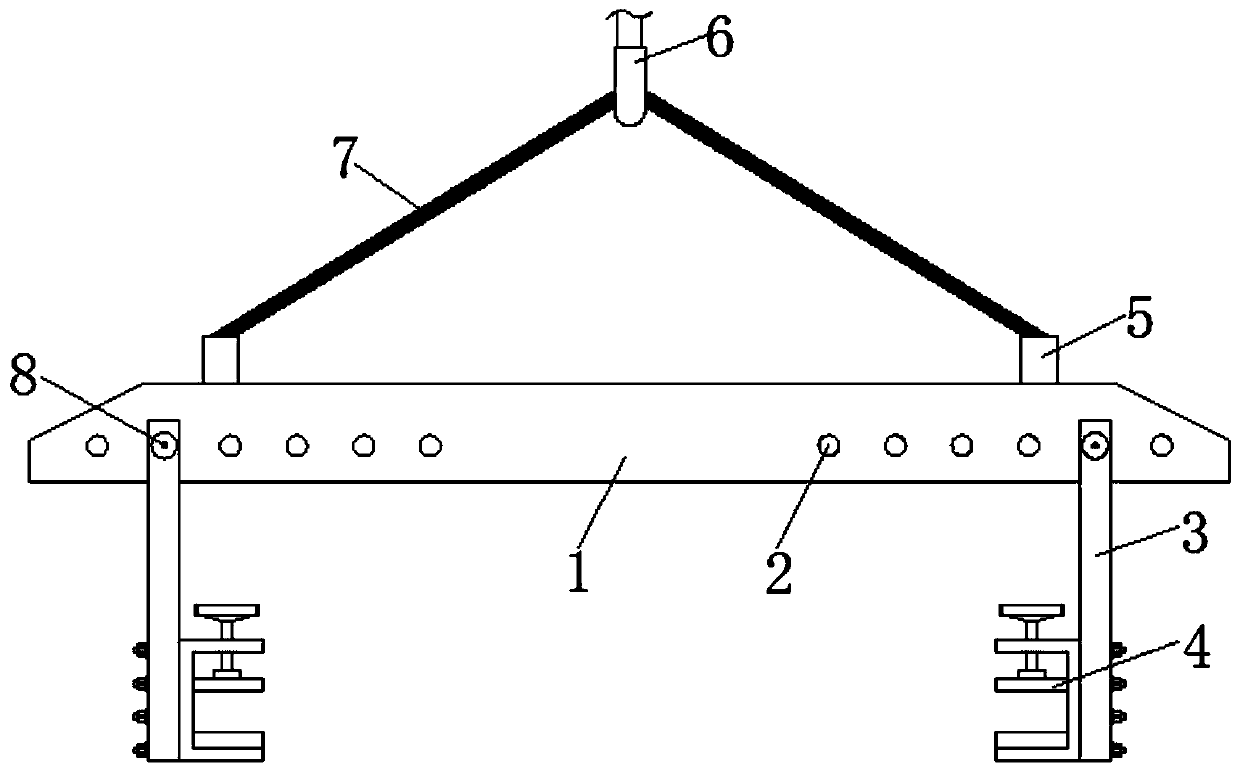

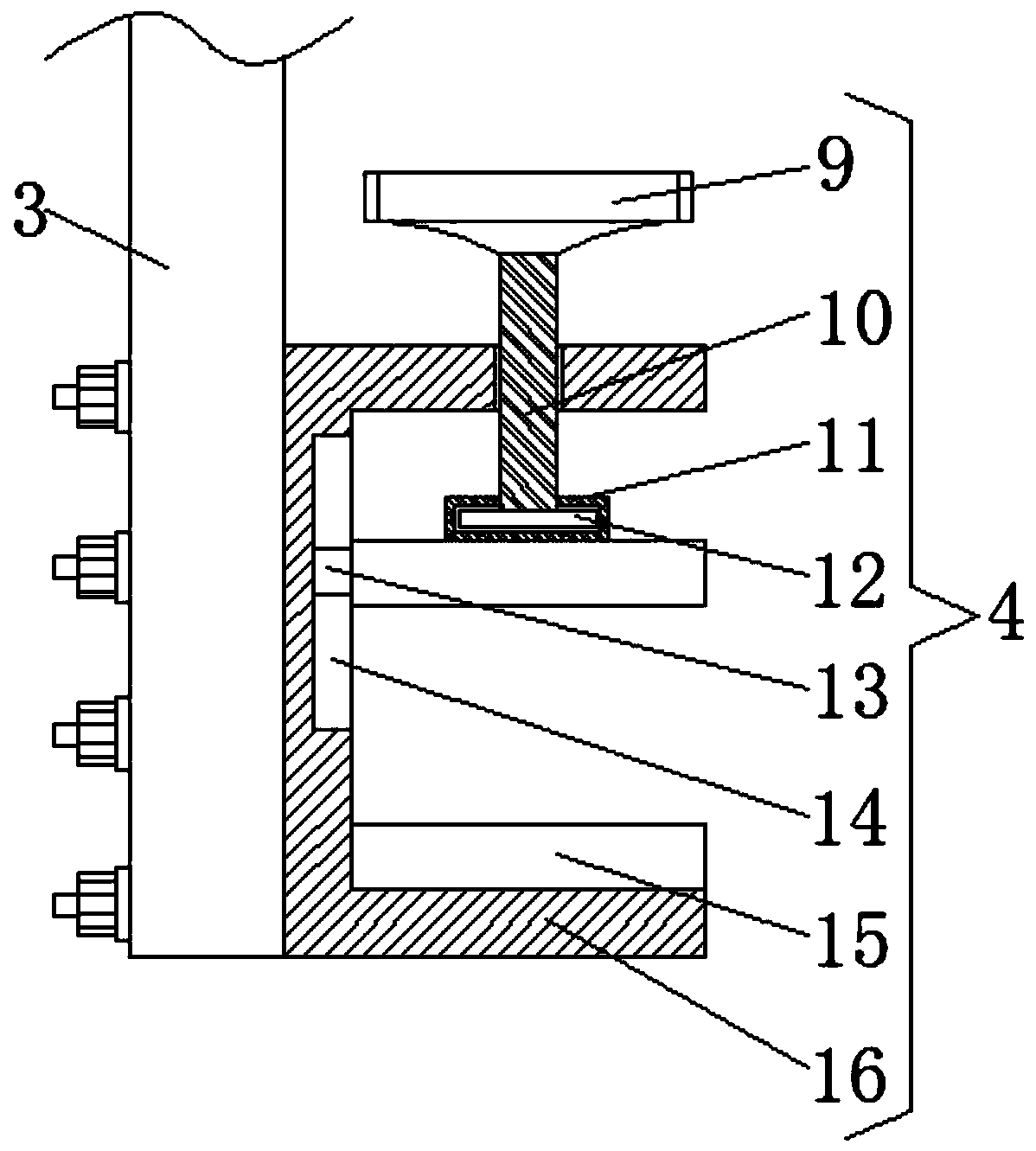

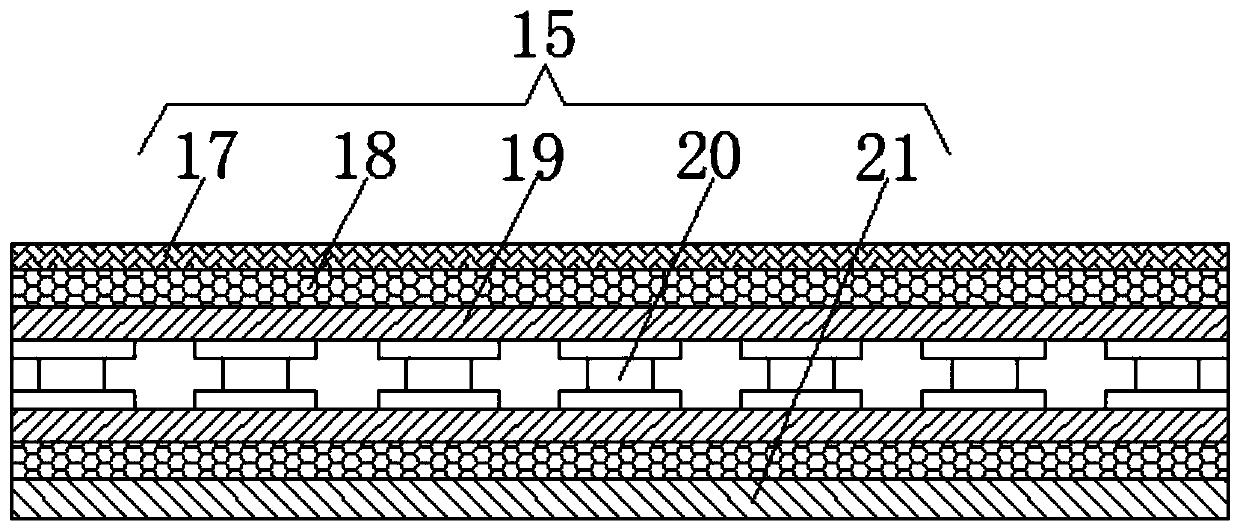

[0022] refer to Figure 1-5 , a steel plate hoisting fixture in steel structure assembly, comprising a beam 1, fixed rings 5 are fixedly installed on both sides of the upper end of the beam 1, steel wire ropes 7 are fixedly installed on the two fixed rings 5, and both ends of the steel wire rope 7 are fixedly installed respectively On the two fixed rings 5, a lifting hook 6 is hung in the middle of the wire rope 7. This design only uses a wire rope 7, and the two ends of the wire rope 7 are fixedly tied to the two fixed rings 5 respectively. Hook 6 is hooked in the middle position of wire rope 7 and gets final product, and hoisting hook 6 is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com