A kind of water-based negative ion paint and preparation method thereof

A negative ion coating, water-based technology, applied in the direction of coating, etc., can solve the problems of poor durability, inability to achieve fresh air, antibacterial and sterilization, etc., and achieve long-term environmental protection performance, not easy to fall off, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

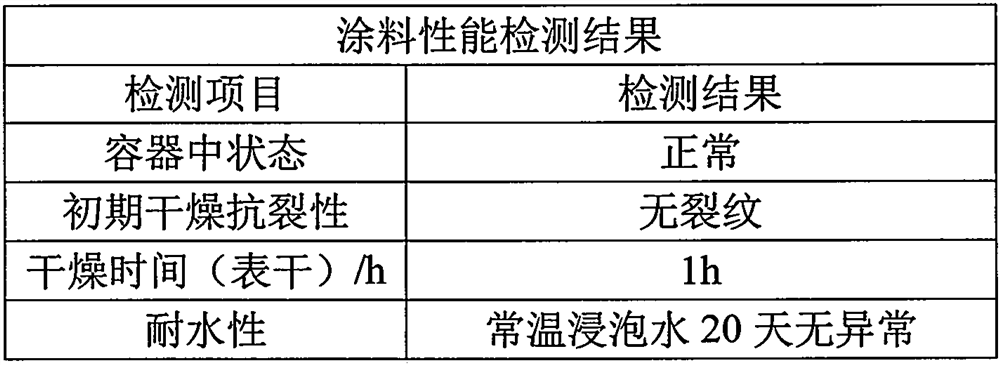

Embodiment 1

[0026] The preparation method of the water-based anion coating of the present embodiment is as follows:

[0027] (1) Add 10g of tourmaline powder, 5g of cerium oxide and 1g of polymerizable borate into a 10% polyethylene glycol (PET-4000) aqueous solution, and ultrasonically disperse it uniformly to obtain a suspension A;

[0028] (2) Mix the suspension A and methyl acrylate for emulsion polymerization to obtain emulsion B; the emulsion polymerization is carried out under the following conditions: under the action of an emulsifier and an initiator, the suspension A reacts with methyl acrylate; The reaction temperature is 50°C, the reaction time is 2 hours, the emulsifier is polyoxyethylene lauryl ether, and the initiator is benzoyl peroxide;

[0029] (3) After mixing emulsion B with cationic block copolymer, styrene-acrylic emulsion, and ethanol evenly, add tetraethyl orthosilicate, stir for 30 minutes, and then water-based negative ion paint can be obtained; wherein, the cat...

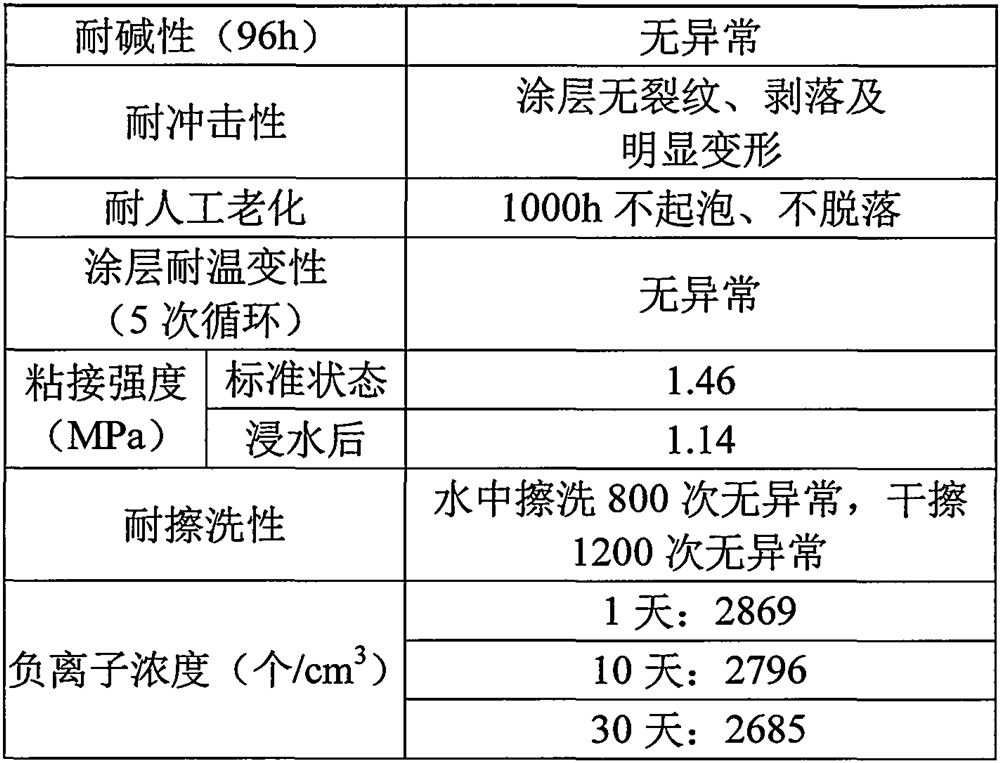

Embodiment 2

[0035] The preparation method of the water-based anion coating of the present embodiment is as follows:

[0036] (1) Add the mixture of 10g tourmaline powder, 4g cerium oxide and 0.5g polymerizable borate into the polyethylene glycol (PET-6000) aqueous solution with a concentration of 20% by mass, and ultrasonically disperse and evenly suspend Liquid A;

[0037] (2) Mix suspension A with methyl methacrylate for emulsion polymerization to obtain emulsion B; the emulsion polymerization is carried out under the following conditions: under the action of emulsifier and initiator, suspension A and methacrylic acid Methyl ester reaction; the reaction temperature is 60°C, the reaction time is 2.5 hours, the emulsifier is polyoxyethylene lauryl ether, and the initiator is benzoyl peroxide;

[0038] (3) After mixing emulsion B with cationic block copolymer, styrene-acrylic emulsion, and methanol evenly, add tetraethyl orthosilicate and stir for 40 minutes to obtain water-based negative...

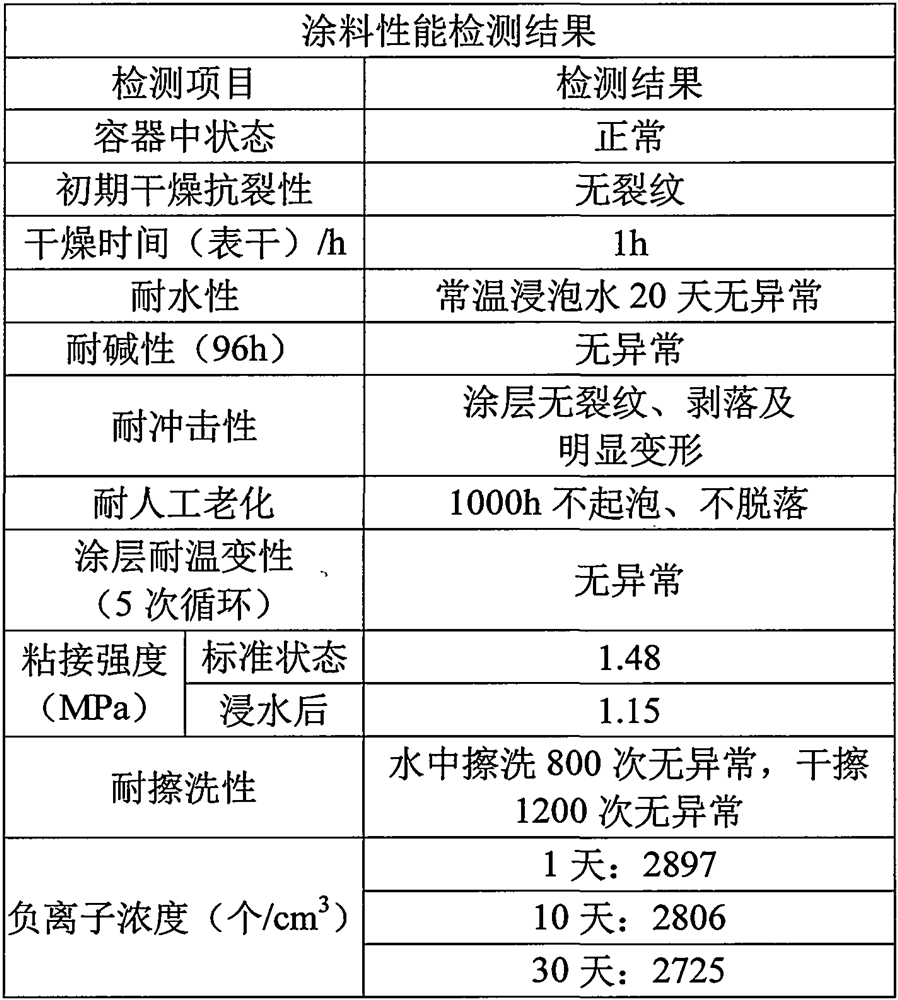

Embodiment 3

[0043] The preparation method of the water-based anion coating of the present embodiment is as follows:

[0044] (1) Add the mixture of 10g tourmaline powder, 4.5g cerium oxide and 0.8g polymerizable boric acid ester to the polyethylene glycol (PET-8000) aqueous solution with a mass percent concentration of 15%, and ultrasonically disperse and evenly suspend Liquid A;

[0045] (2) Mix the suspension A and methacrylic acid for emulsion polymerization to obtain emulsion B; the emulsion polymerization is carried out under the following conditions: under the action of an emulsifier and an initiator, the suspension A reacts with methacrylic acid; The reaction temperature is 55°C, the reaction time is 3 hours, the emulsifier is polyoxyethylene lauryl ether, and the initiator is benzoyl peroxide;

[0046] (3) After mixing emulsion B with cationic block copolymer, styrene-acrylic emulsion, and isopropanol, add tetraethyl orthosilicate and stir for 40 minutes to obtain water-based neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com