Novel negative oxygen ion coating and preparation method thereof

A technology of negative oxygen ion and negative oxygen ion powder, which is applied in the field of coatings, can solve the problem that the gloss and flatness of negative oxygen ion coatings cannot meet the texture requirements of decorative panels, and achieves good film-forming properties, high gloss, The effect of increasing the number of releases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

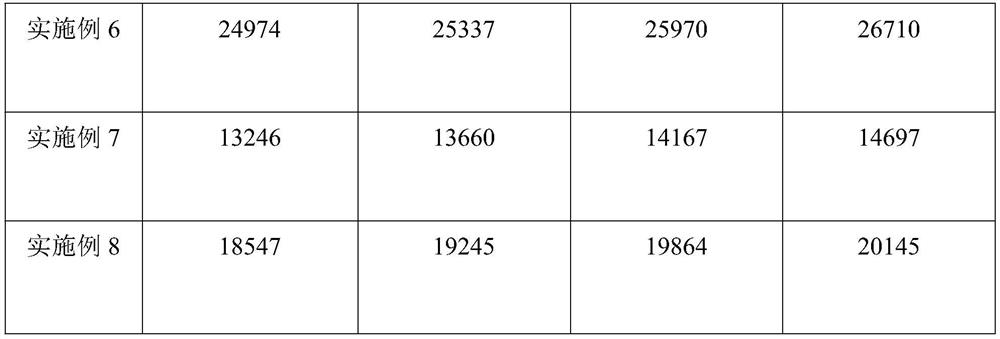

Examples

Embodiment 1

[0026] The invention provides a novel negative oxygen ion coating, which comprises the following components and proportions in parts by weight: 5 parts of negative oxygen ion powder, 0.5 parts of nano-silica powder, 0.5 parts of bactericide nano-silver colloidal solution, 15 parts of water-based polyurethane resin, 3 parts of xanthoxylin, 0.1 part of NXZ defoamer, 0.5 parts of dispersant SN-50400, 30 parts of water, 2 parts of trimethylolpropane-tris(3-aziridinyl)propionate.

[0027] The present invention also provides a kind of preparation method of novel negative oxygen ion coating, comprises the following steps:

[0028] Step S1: Prepare the bactericide: Mix the aqueous solution of cyclodextrin with a mass fraction of 5% and the silver ammonia solution with a molar concentration of 0.5 mol / L at a volume ratio of 1:100, and stir for 100 minutes at a temperature of 80°C to obtain It is standby for the nano-silver colloid solution that average particle size is 50nm;

[0029] ...

Embodiment 2

[0031] The invention provides a novel negative oxygen ion coating, which comprises the following components and proportions in parts by weight: 10 parts of negative oxygen ion powder, 1.0 parts of nano-silica powder, 1.0 parts of bactericide nano-silver colloidal solution, 20 parts of water-based polyurethane resin, 5 parts of xanthoxylin, 0.5 part of NXZ defoamer, 1.0 part of dispersant SN-5040, 40 parts of water, 5 parts of trimethylolpropane-tris(3-aziridinyl)propionate.

[0032] The present invention also provides a kind of preparation method of novel negative oxygen ion coating, comprises the following steps:

[0033] Step S1: Prepare the bactericide: use a cyclodextrin aqueous solution with a mass fraction of 10% and a silver ammonia solution with a molar concentration of 1.0 mol / L to mix at a volume ratio of 1:10, and stir for 120 minutes at a temperature of 100°C to obtain It is standby for the nano-silver colloid solution that average particle diameter is 100nm;

[0...

Embodiment 3

[0036] The invention provides a novel negative oxygen ion coating, which comprises the following components and proportions in parts by weight: 8 parts of negative oxygen ion powder, 0.8 parts of nano-silica powder, 0.8 parts of bactericide nano-silver colloidal solution, 18 parts of water-based polyurethane resin, 4 parts of xanthoxylin, 0.4 part of NXZ defoamer, 0.8 parts of dispersant SN-50400, 35 parts of water, 3 parts of trimethylolpropane-tris(3-aziridinyl)propionate.

[0037] The present invention also provides a kind of preparation method of novel negative oxygen ion coating, comprises the following steps:

[0038] Step S1: Prepare the fungicide: Mix the aqueous solution of cyclodextrin with a mass fraction of 8% and the silver ammonia solution with a molar concentration of 0.5-1.0 mol / L at a volume ratio of 1:50, and stir for 110 minutes at a temperature of 90°C. Promptly obtain the nanometer silver colloid solution that average particle diameter is 80nm for subseque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com