Preparation method of high-temperature-resistant thermoplastic hot melt adhesive for furniture edge sealing

A hot melt adhesive, warm technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of wire drawing dirty boards, etc., to achieve improved temperature resistance, low cost, good bonding effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

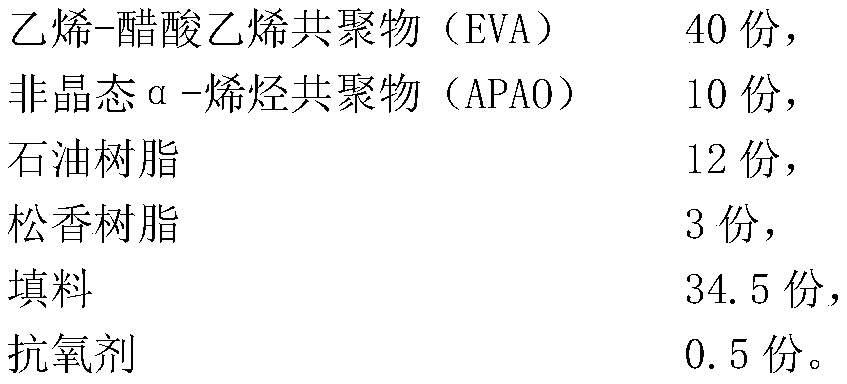

[0015] A high-temperature-resistant thermoplastic furniture edge-sealing hot-melt adhesive, which includes the following components in parts by weight:

[0016]

[0017] The antioxidant is pentaerythritol tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

[0018] A preparation method of a high-temperature-resistant thermoplastic furniture edge-sealing hot melt adhesive, the preparation method comprising the following steps:

[0019] (1) Put EVA, APAO and tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol into the kneader, start heating and knead evenly, the kneading frequency is 22Hz, the reaction The temperature of the material in the kettle is controlled at 160°C, and heated until the material is completely melted;

[0020] (2) Put petroleum resin and rosin resin in a specified proportion into the molten material in step 1 and knead evenly, the kneading frequency is 33 Hz, knead until the material is completely melted, and reduce the tempe...

Embodiment 2

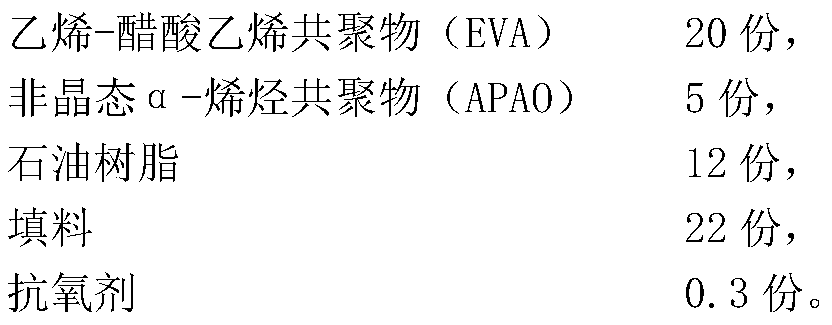

[0025] A high-temperature-resistant thermoplastic furniture edge-sealing hot-melt adhesive, which includes the following components in parts by weight:

[0026]

[0027] The antioxidant is a mixture of 2,6-di-tert-butyl-4-methylphenol and tris[2.4-di-tert-butylphenyl]phosphite.

[0028] A preparation method of a high-temperature-resistant thermoplastic furniture edge-sealing hot melt adhesive, the preparation method comprising the following steps:

[0029] (1) Put EVA, APAO, 2,6-di-tert-butyl-4-methylphenol and tris[2.4-di-tert-butylphenyl]phosphite into the kneader, start heating and knead evenly, the kneading frequency 15Hz, the temperature of the material in the reactor is controlled at 150°C, and heated until the material is completely melted;

[0030] (2) Put petroleum resin and rosin resin in a specified proportion into the melted material in step 1 and knead evenly, the kneading frequency is 27 Hz, knead until the material is completely melted, and reduce the temper...

Embodiment 3

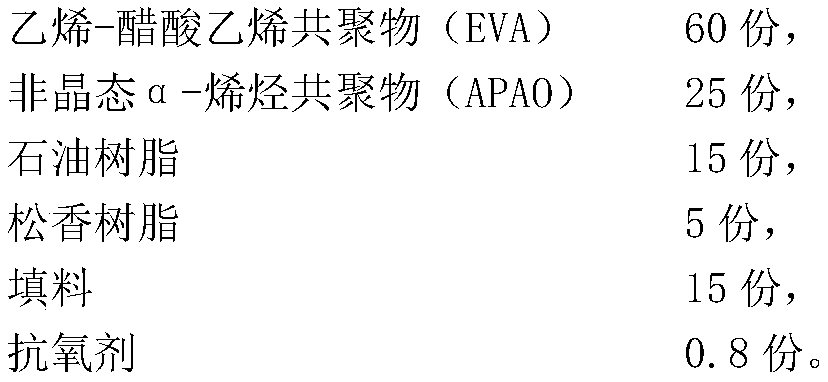

[0035] A high-temperature-resistant thermoplastic furniture edge-sealing hot-melt adhesive, which includes the following components in parts by weight:

[0036]

[0037] The antioxidant is tris[2.4-di-tert-butylphenyl]phosphite.

[0038] A preparation method of a high-temperature-resistant thermoplastic furniture edge-sealing hot melt adhesive, the preparation method comprising the following steps:

[0039] (1) Put EVA, APAO and tris[2.4-di-tert-butylphenyl]phosphite into the kneader, start heating and knead evenly, the kneading frequency is 25Hz, the temperature of the material in the reactor is controlled at 180°C, and the material is heated until all melted;

[0040] (2) Put petroleum resin and rosin resin in a specified proportion into the material melted in step 1 and knead evenly, the kneading frequency is 40 Hz, knead until the material is completely melted, and reduce the temperature of the material to 150 ° C;

[0041] (3) Slowly drop into barium sulfate in the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap