Expressway surface concrete layer leveling equipment and levelling method

A technology for expressways and concrete layers, which is applied in the field of building construction, can solve the problems affecting the concrete leveling process of large-area thin-layer structures on expressways, and the difficulty of covering the curing film, and achieves novel structure, high degree of automation, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

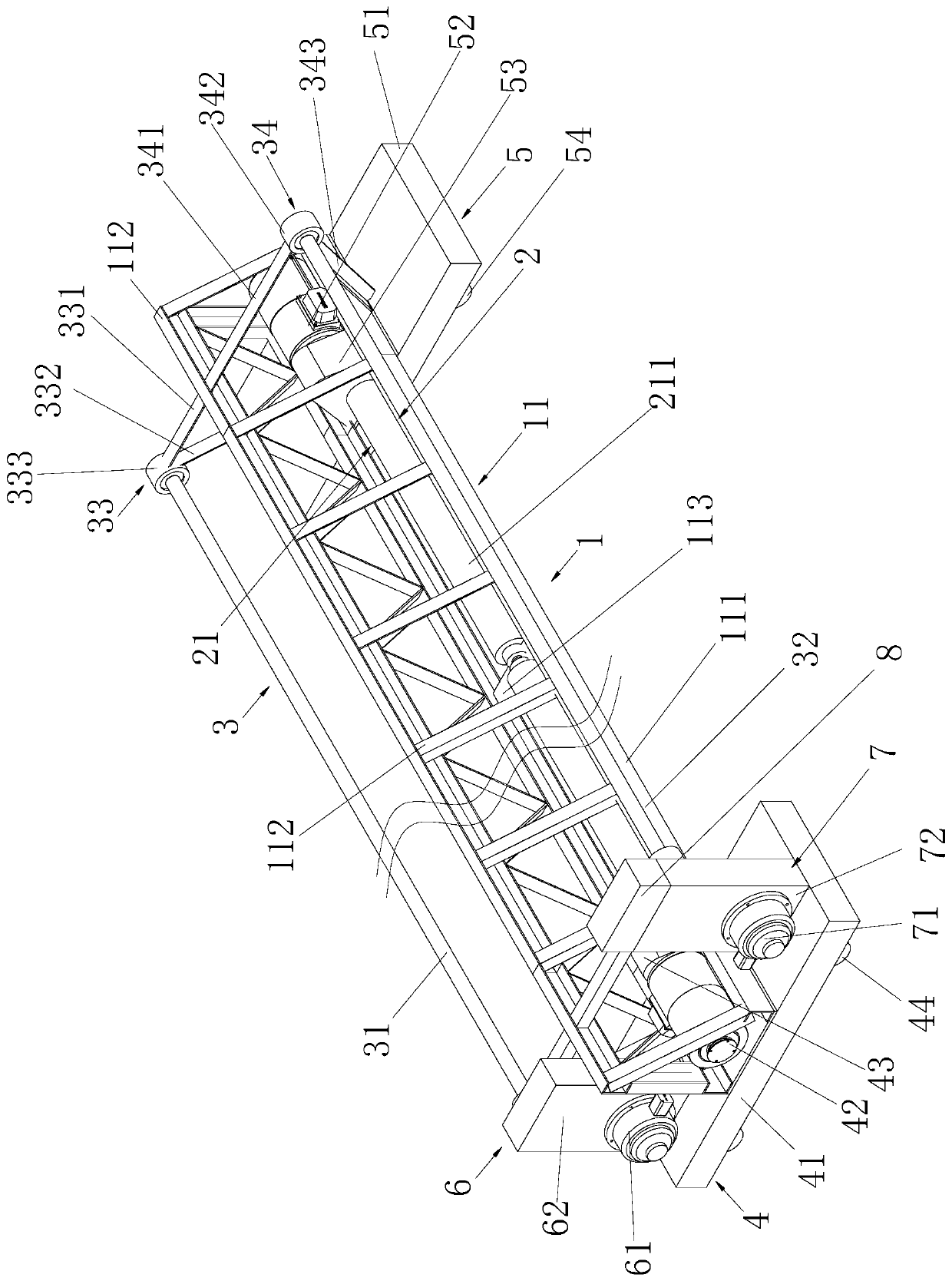

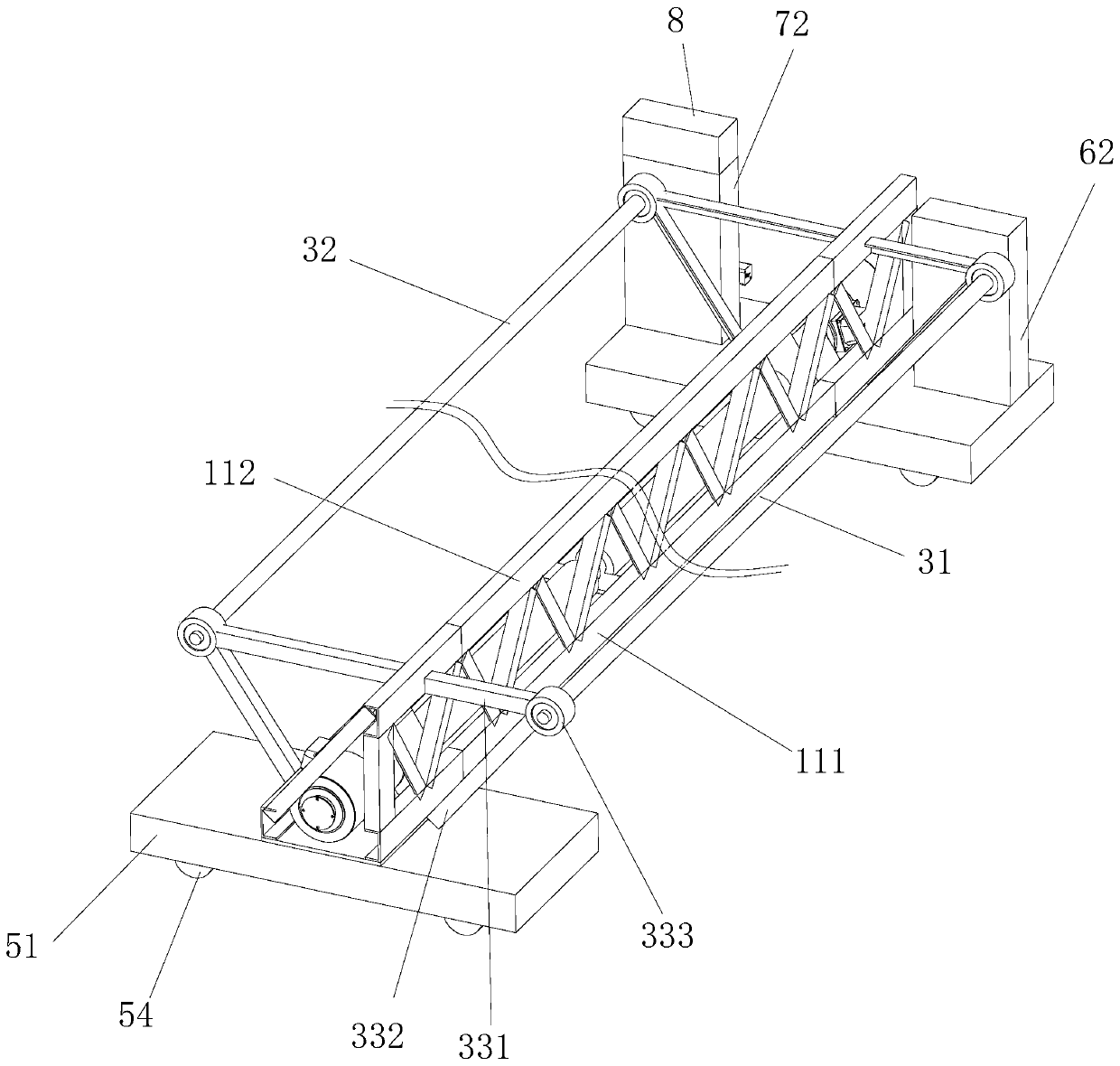

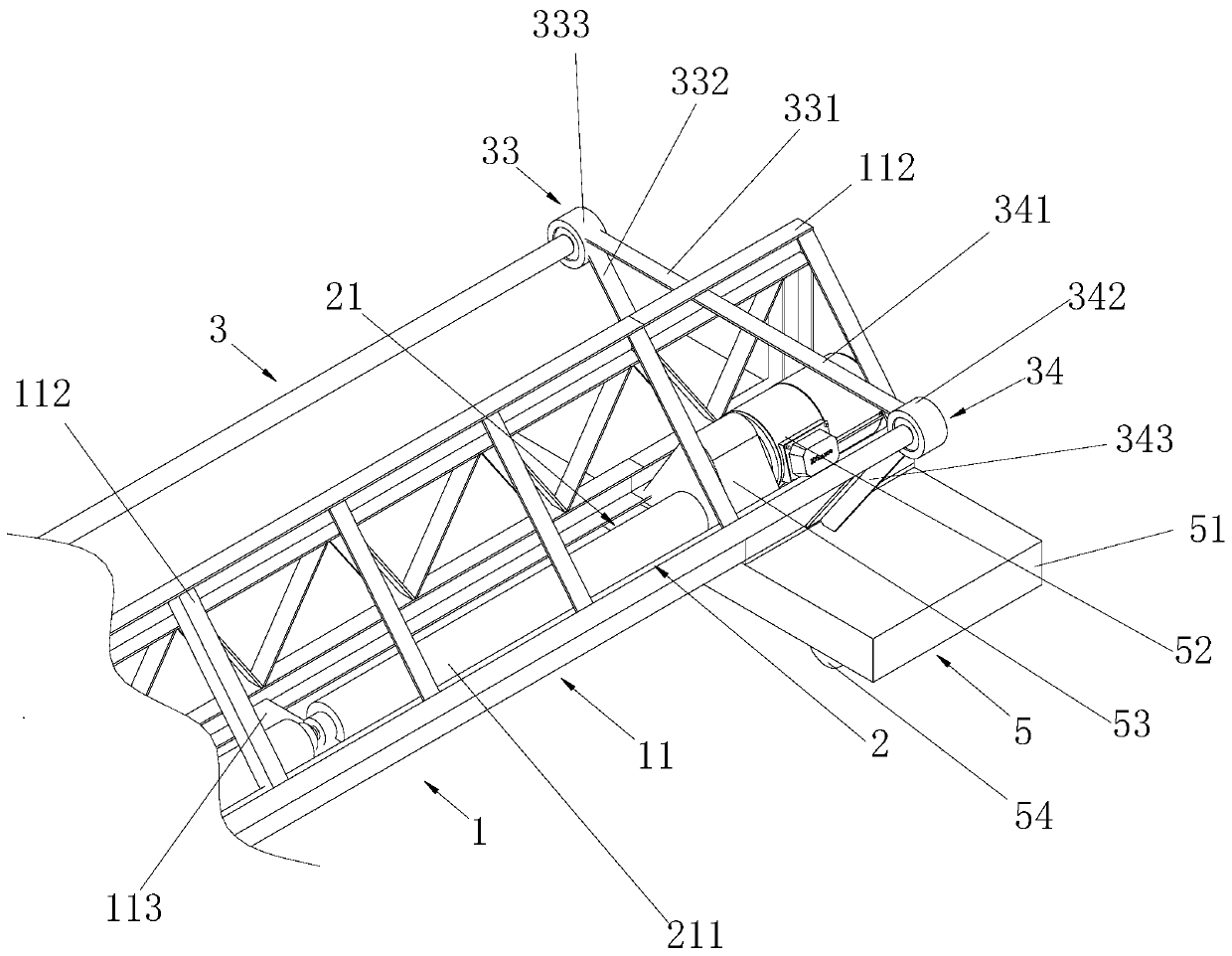

[0036] combine Figure 1 to Figure 5 , a highway surface concrete layer leveling equipment, including a traveling device 1 advancing along the highway, a round roller leveling device 2 and a rolling film device 3.

[0037] The traveling device 1 includes a main frame 11 , the two ends of the main frame 11 are respectively connected with a first moving mechanism 4 and a second moving mechanism 5 , and the round roller leveling device 2 is arranged in the main frame 11 .

[0038] The film rolling device 3 includes a first film rolling rod 31 and a second film rolling rod 32, the first film rolling rod 31 is arranged on one side of the main body frame 11, and the first film rolling rod 31 is arranged on the front side of the main body frame 11 in the present invention .

[0039] One end of the first film rolling rod 31 is connected to the first moving mechanism 4 through the first film rolling motor assembly 6 , and the other end is connected to the second moving mechanism 5 thr...

Embodiment 2

[0053] The leveling method of the above-mentioned expressway surface concrete layer leveling equipment specifically includes the following steps:

[0054] Step 1, adjusting the travel speed of the first moving mechanism 4 and the second moving mechanism 5;

[0055] The adjustment of the speed of travel of the first moving mechanism 4 and the second moving mechanism 5 is realized by adjusting the first three-phase asynchronous motor 42 and the second three-phase asynchronous motor 52;

[0056] Step 2, adjusting the rotation speeds of the first film rolling motor 61 and the second film rolling motor 71 in the traveling direction;

[0057] Before the first roll-up film motor 61 and the second roll-up film motor 71 rotated, the first roll-up film rod 31 and the second roll-up film rod 32 were all wound with a film for covering the wet concrete surface of the highway. Because the surface of the expressway needs to be smoothed multiple times, the role of the film covering the surfa...

Embodiment 3

[0064] The above-mentioned expressway surface concrete layer leveling equipment is first provided with a round roller leveling device 2 for smoothing the expressway surface concrete layer. The circular roller leveling device 2 initially smoothes the concrete mortar layer, avoiding workers to level a large amount of concrete mortar during the smoothing process, improving the leveling efficiency and saving a lot of manpower and material resources. Simultaneously the present application is provided with the movable first moving mechanism 4 and the second moving mechanism 5, and the first three-phase asynchronous motor 42 and the second three-phase asynchronous motor 52 provide power, avoiding artificially promoting the main body frame 11, improving the overall Ease of movement. The film rolling device 3 that is used to cover the expressway surface is also provided in the present invention, and the first film rolling bar 31 and the second film rolling bar 32 are arranged on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com