Swinging type power driving device for power generation

A power-driven, oscillating technology, applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of one-way bearings that cannot meet the demand, frequent replacement of one-way bearings, etc., to meet the needs of high-torque one-way transmission, torque The effect of increasing and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

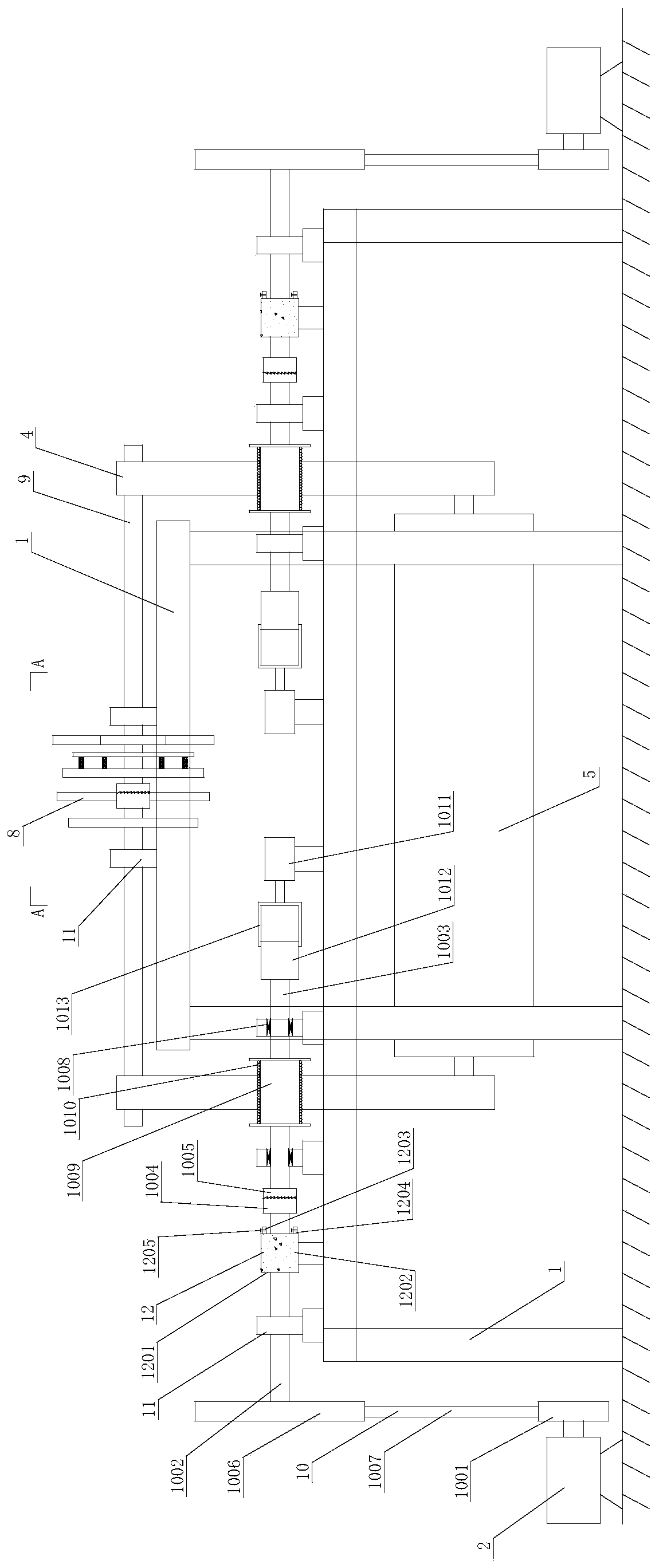

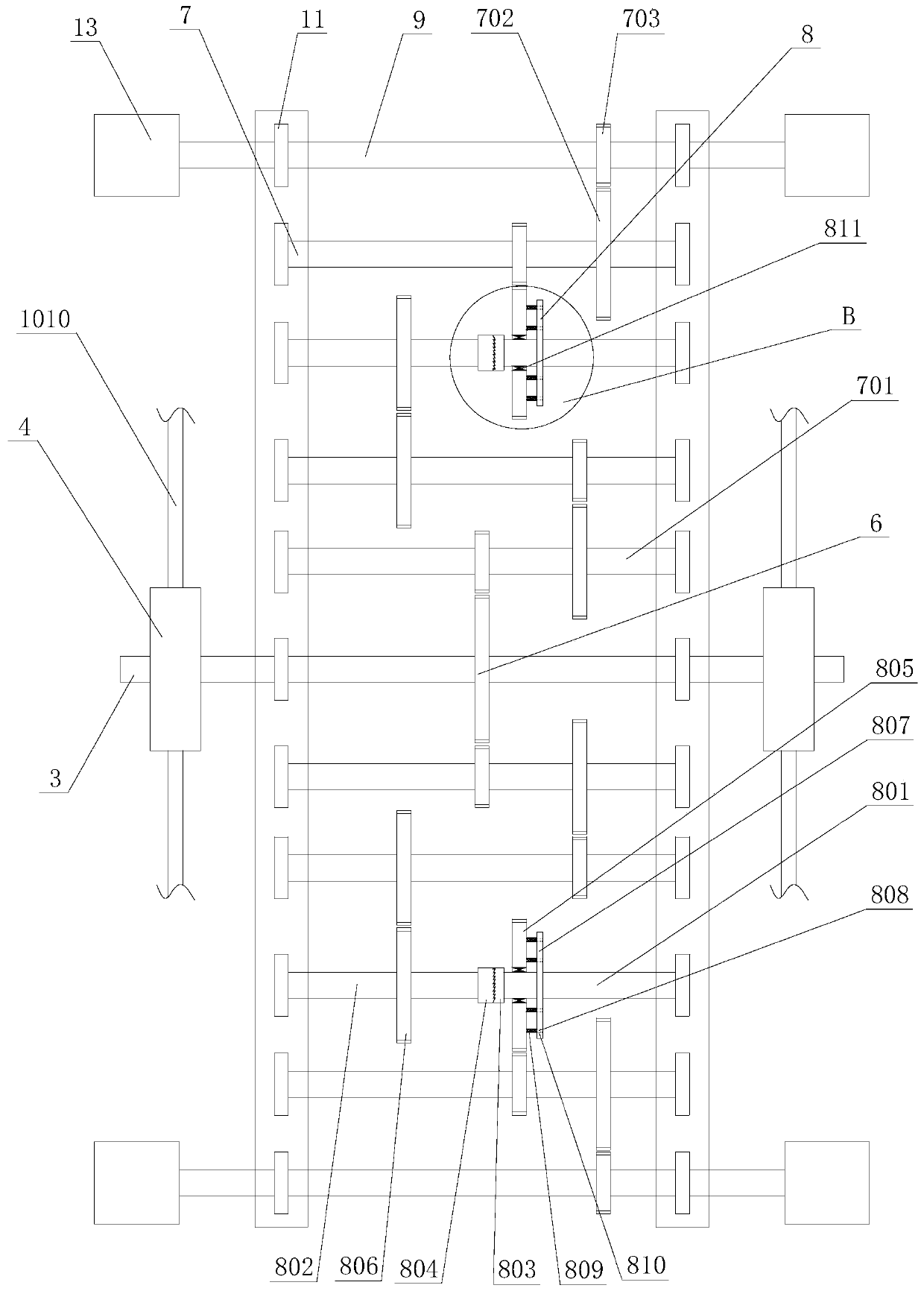

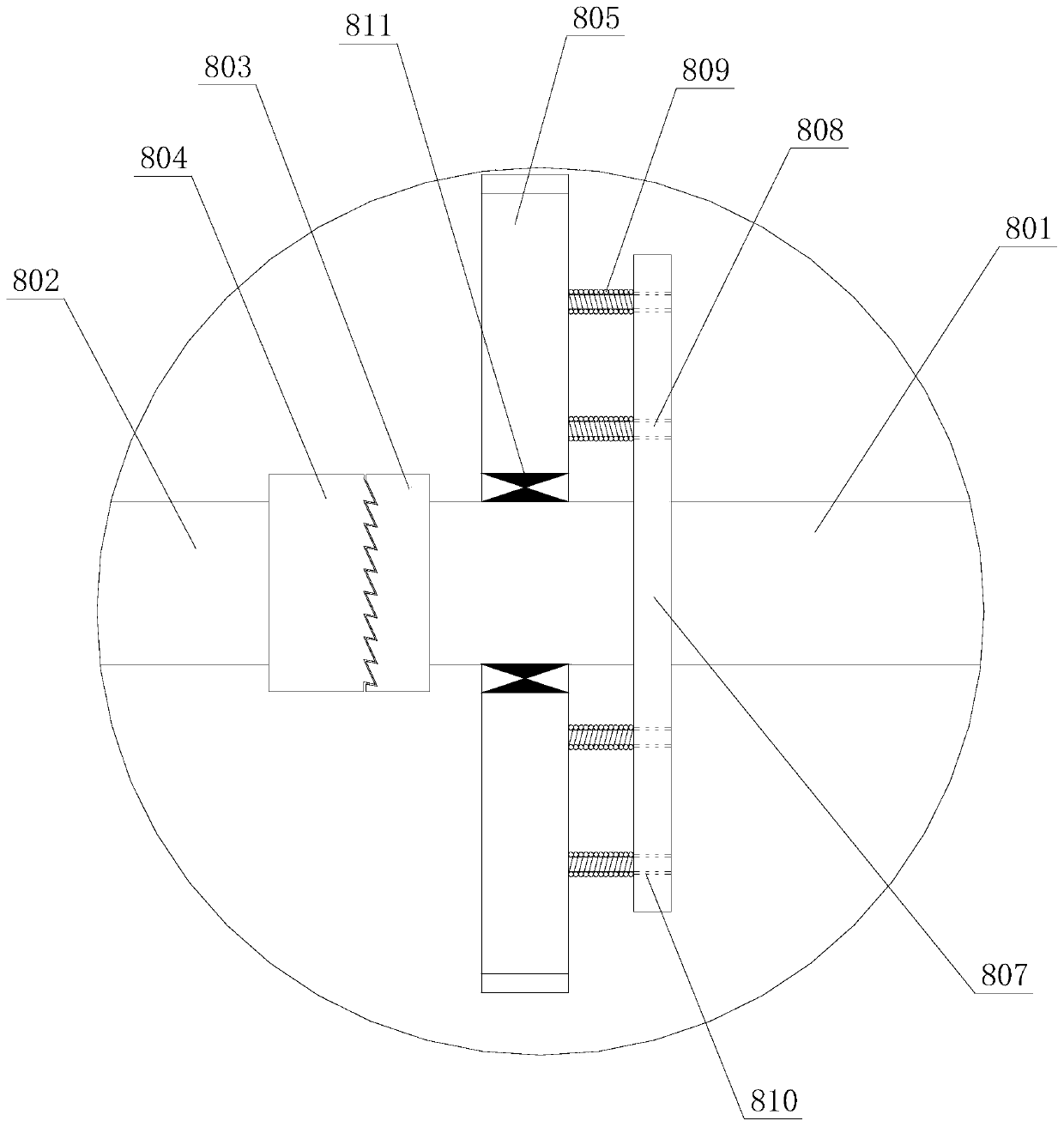

[0022] like figure 1 As shown, the present invention provides a swing type power drive device for power generation, including a frame 1, a servo motor 2, the servo motor 2 is used, and the frame 1 is rotatably connected with a main drive shaft 3, the implementation In the example, a rotating bearing seat 11 is arranged between the frame 1 and the main transmission shaft 3 to realize its rotational connection. Both ends of the main transmission shaft 3 are fixedly connected with a vertically arranged swing arm 4, and the lower end of the swing arm 4 is fixedly connected. There is a counterweight 5, the middle fixed sleeve of the main transmission shaft 3 is provided with a main transmission gear 6, and the two sides of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com