Shunting type sampling and emptying device for centrifugal pump

A centrifugal pump and shunt-type technology, which is applied in the direction of sampling devices, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of inconvenient control of the flow rate, high requirements for physical strength and arm strength of operators, and reduce sampling Difficulty, accurate and convenient sampling, easy disassembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

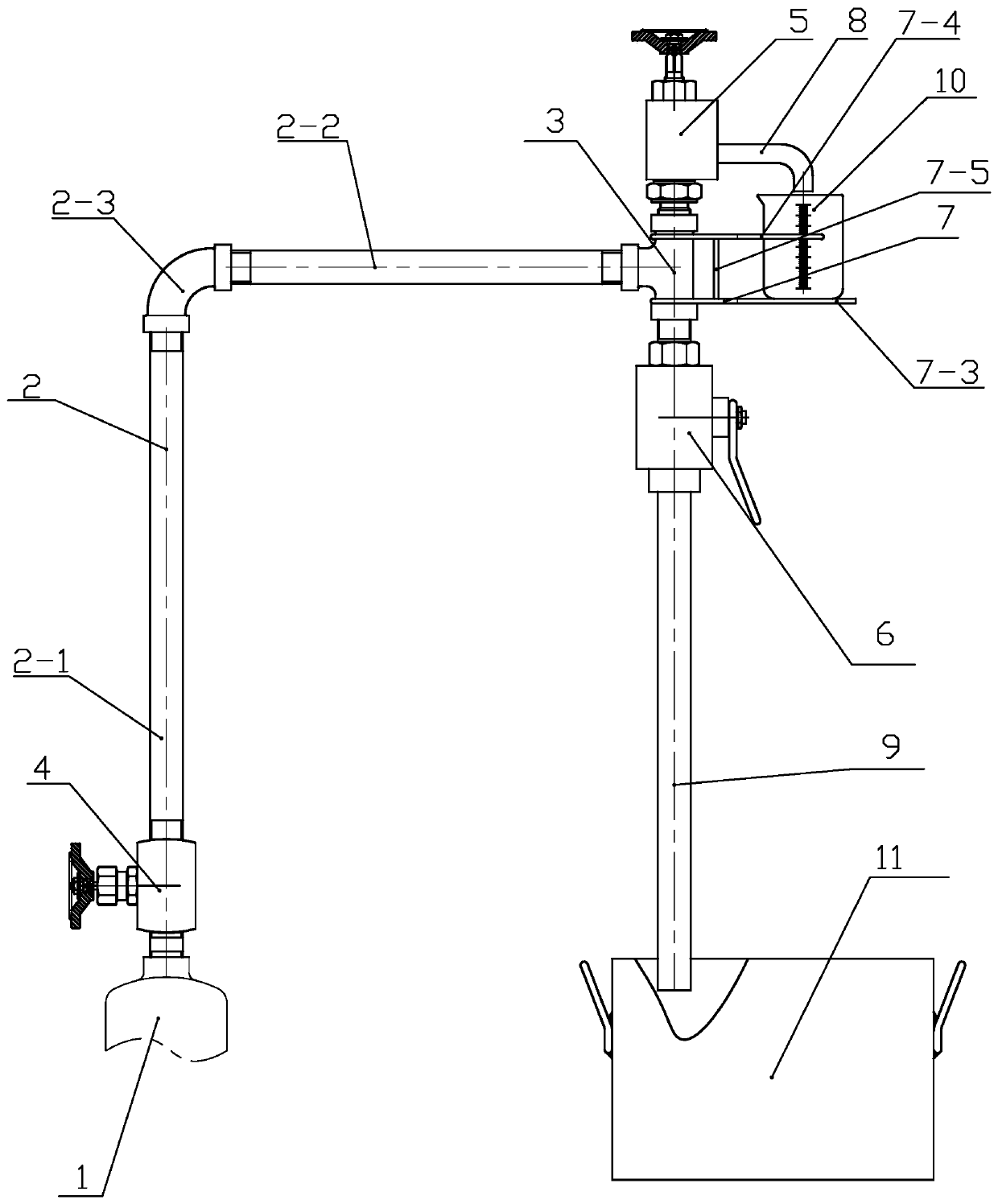

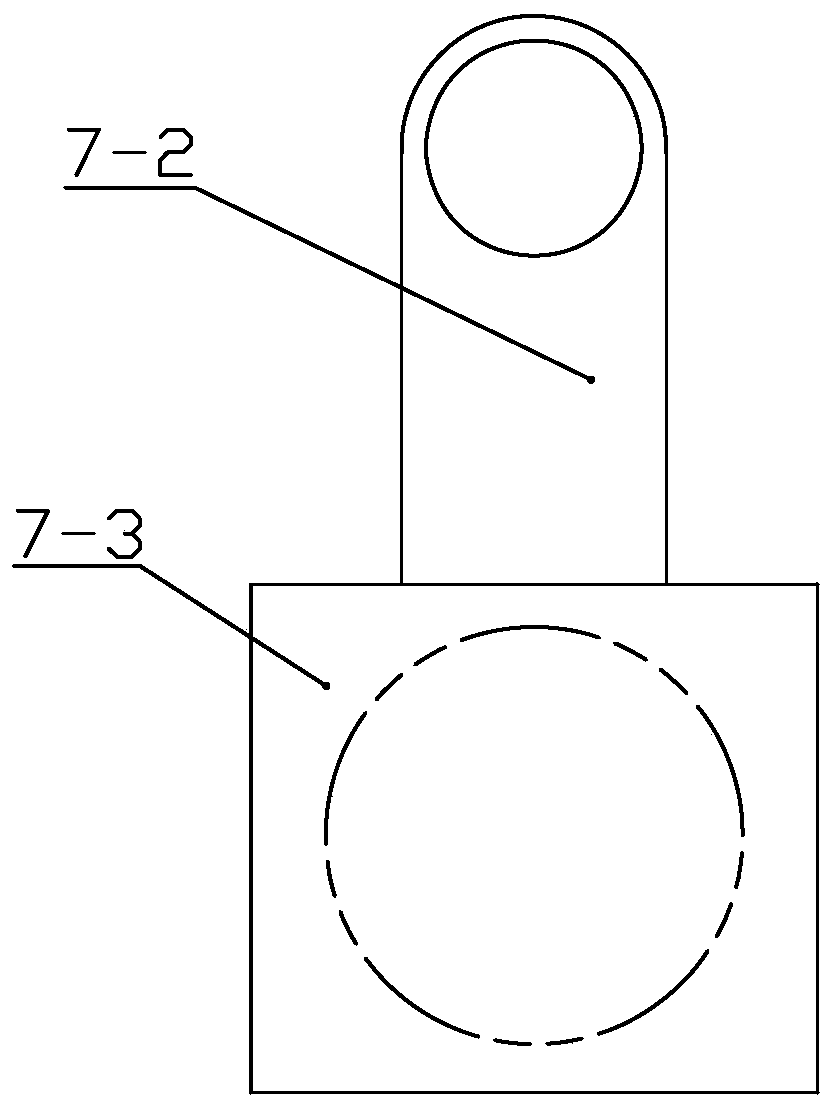

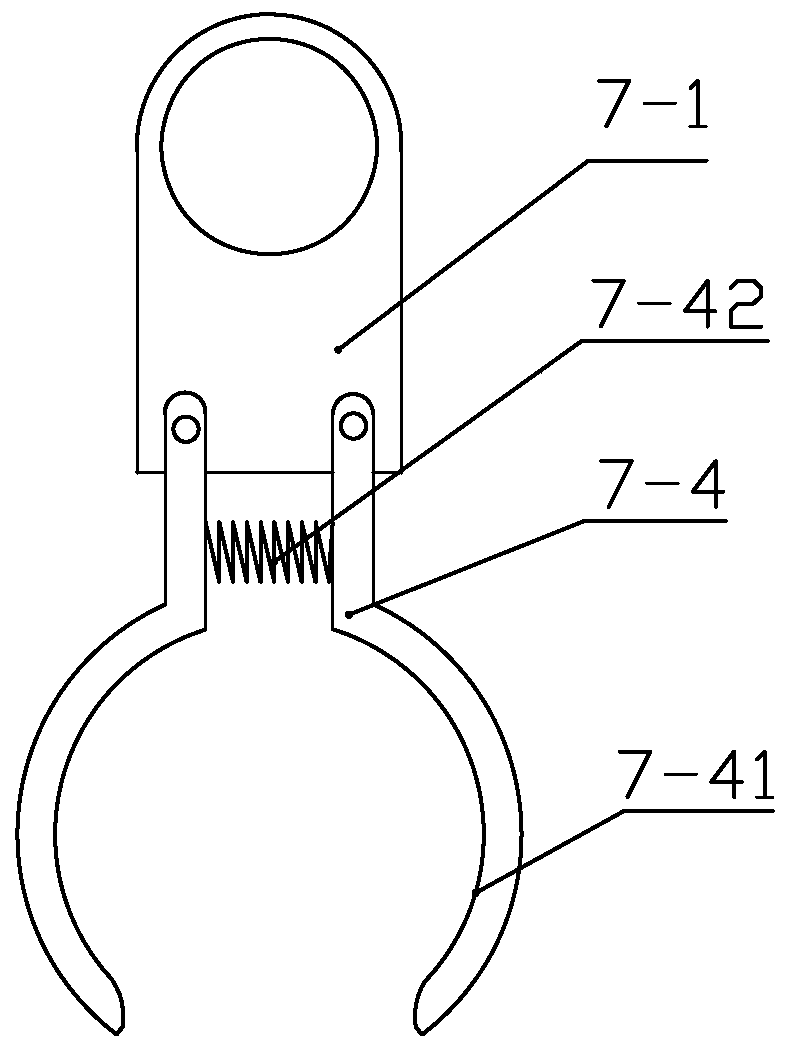

[0016] Embodiment 1: Combining Figures 1 to 3 Describe this embodiment, a centrifugal pump with a split-flow sampling and venting device, which includes a centrifugal pump 1, a main pipeline 2, a three-way 3, a stop valve 4, a sampling valve 5, a venting ball valve 6 and a measuring cup holder 7, and the main pipeline 2. One end is fixedly connected with the centrifugal pump 1, the other end of the main pipeline 2, the sampling valve 5 and the emptying ball valve 6 are communicated and arranged through the three-way 3, the shut-off valve 4 is arranged on the main pipeline 2, and the fluid outlet of the sampling valve 5 is connected to a solid. A sampling tube 8 is provided, a venting tube 9 is connected and fixed at the fluid outlet of the venting ball valve 6 , and the measuring cup holder 7 is fixedly arranged between the sampling valve 5 and the venting ball valve 6 . The main pipeline 2 is the top outlet pipeline of the centrifugal pump 1 . The venting ball valve 6 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com