Damage detection device and detection method

A technology for damage detection and detection modules, applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve problems such as unproposed solutions, achieve the effects of intelligent correction, ensure accuracy, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

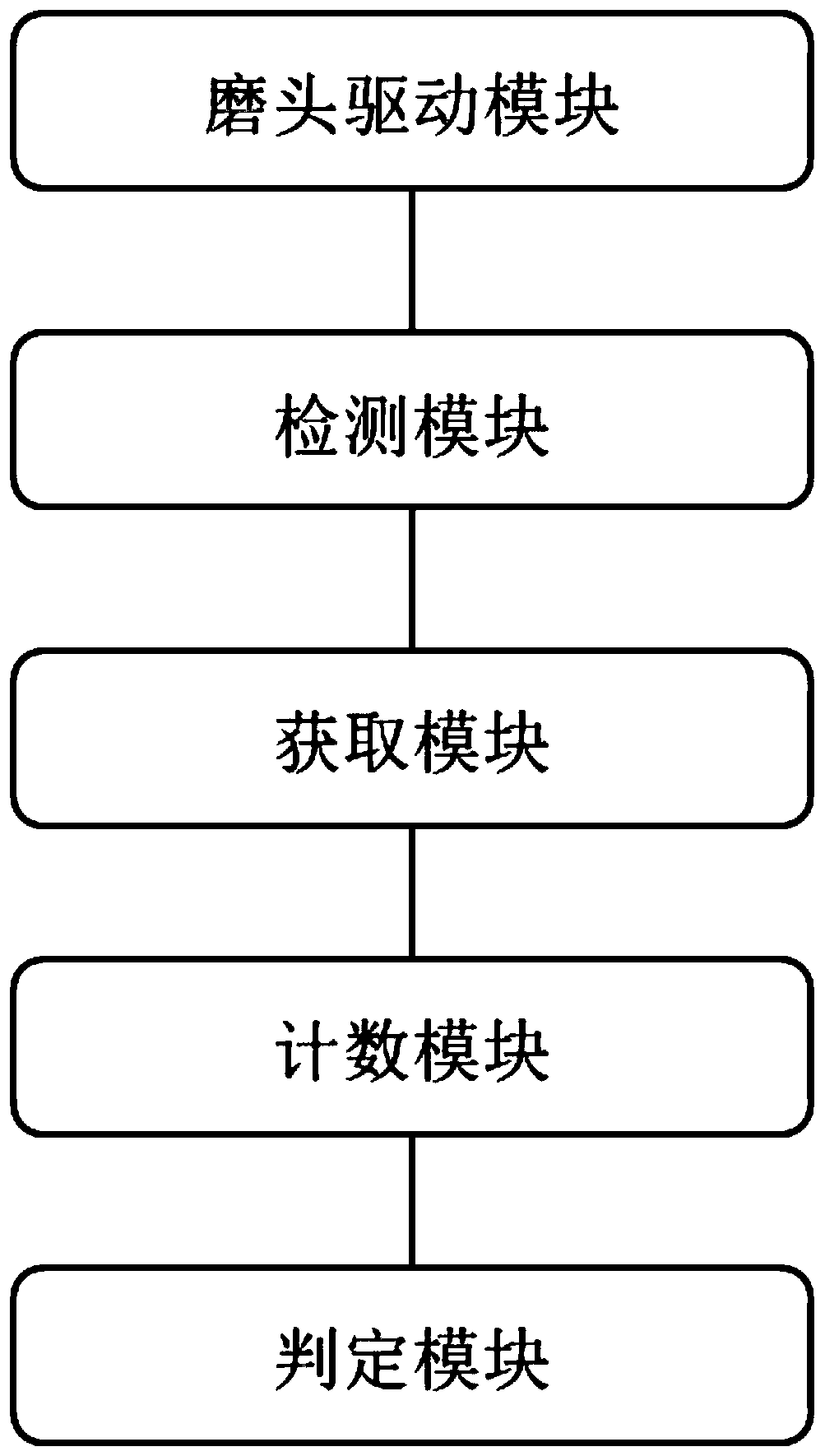

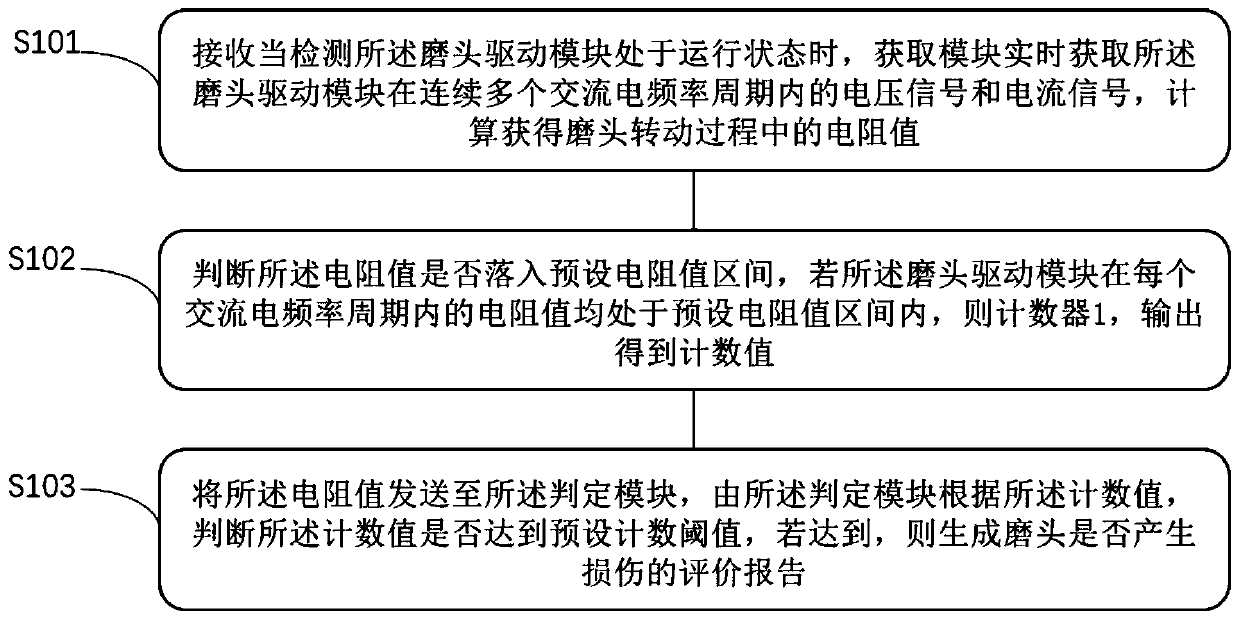

[0031]This embodiment provides a damage detection device. According to the motor motion equation in the grinding head drive module, it is obtained that the electromagnetic torque output by the frequency converter can reflect the load torque of the grinding head drive module, and when the grinding head drive module When the grinding head of the load is damaged, such as cracks and damaged parts of the grinding head, the load torque of the grinding head drive module shows a larger periodic change than normal. At the same time, due to the damage of the grinding head, at the same input current Under normal circumstances, the distributed voltage of the grinding head drive module will also change due to the change of the load torque, and then the overall resistance value of the joint grinding head will change dynamically. Therefore, by detecting the resistance value reflecting the electromagnetic torque, it can be Determine whether the current operation of the grinding head drive modu...

Embodiment 2

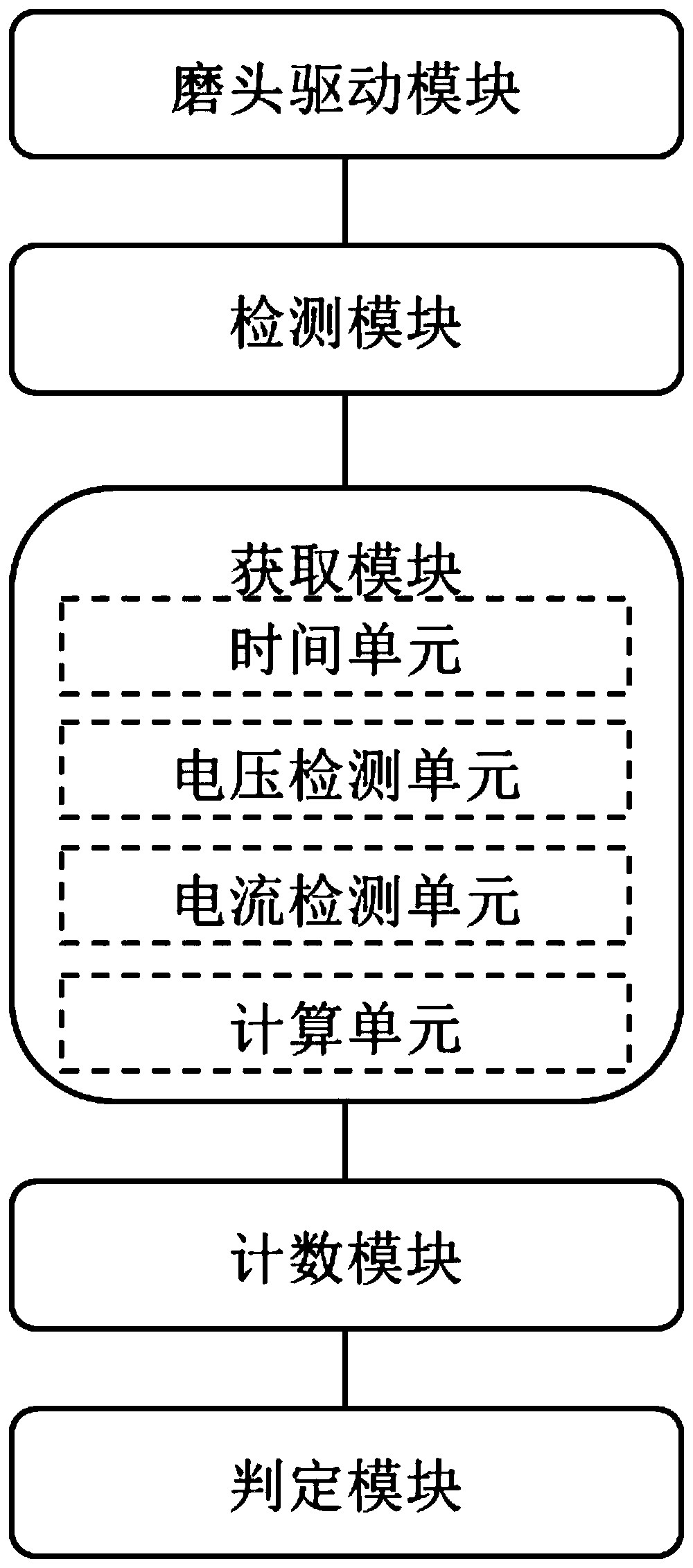

[0043] This embodiment provides a damage detection device. According to the motor motion equation in the grinding head drive module, it is obtained that the electromagnetic torque output by the frequency converter can reflect the load torque of the grinding head drive module, and when the grinding head drive module When the grinding head of the load is damaged, such as cracks and damaged parts of the grinding head, the load torque of the grinding head drive module shows a larger periodic change than normal. At the same time, due to the damage of the grinding head, at the same input current Under normal circumstances, the distributed voltage of the grinding head drive module will also change due to the change of the load torque, and then the overall resistance value of the joint grinding head will change dynamically. Therefore, by detecting the resistance value reflecting the electromagnetic torque, it can be Determine whether the current operation of the grinding head drive mod...

Embodiment 3

[0057] This embodiment is basically the same as Embodiment 2, except that the acquisition module in the damage detection device further includes an environment detection unit and a normal wear compensation unit, wherein the environment detection unit is used to detect the ambient temperature information, and is used to correct the resistance value obtained by the acquisition module, so as to ensure the accuracy of the damage detection of the grinding head; the normal wear compensation unit is used to obtain the normal loss information, used to correct the resistance value obtained by the obtaining module according to the normal loss information.

[0058] In addition, the damage detection device also includes a memory and a processor, the memory is used to store one or more programs in a computer-readable storage medium, and the one or more programs include instructions, and when the instructions are executed by the computer The computer is made to execute the method for detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com