Fresh juice automatic vending machine

A vending machine and fruit juice technology, which is applied in fruit pitting devices, household machinery and instruments for filtering food, etc., can solve the problems of residues, large space occupation of vending machines, etc., and meet hygienic requirements , Guarantee the taste of juice and prevent pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

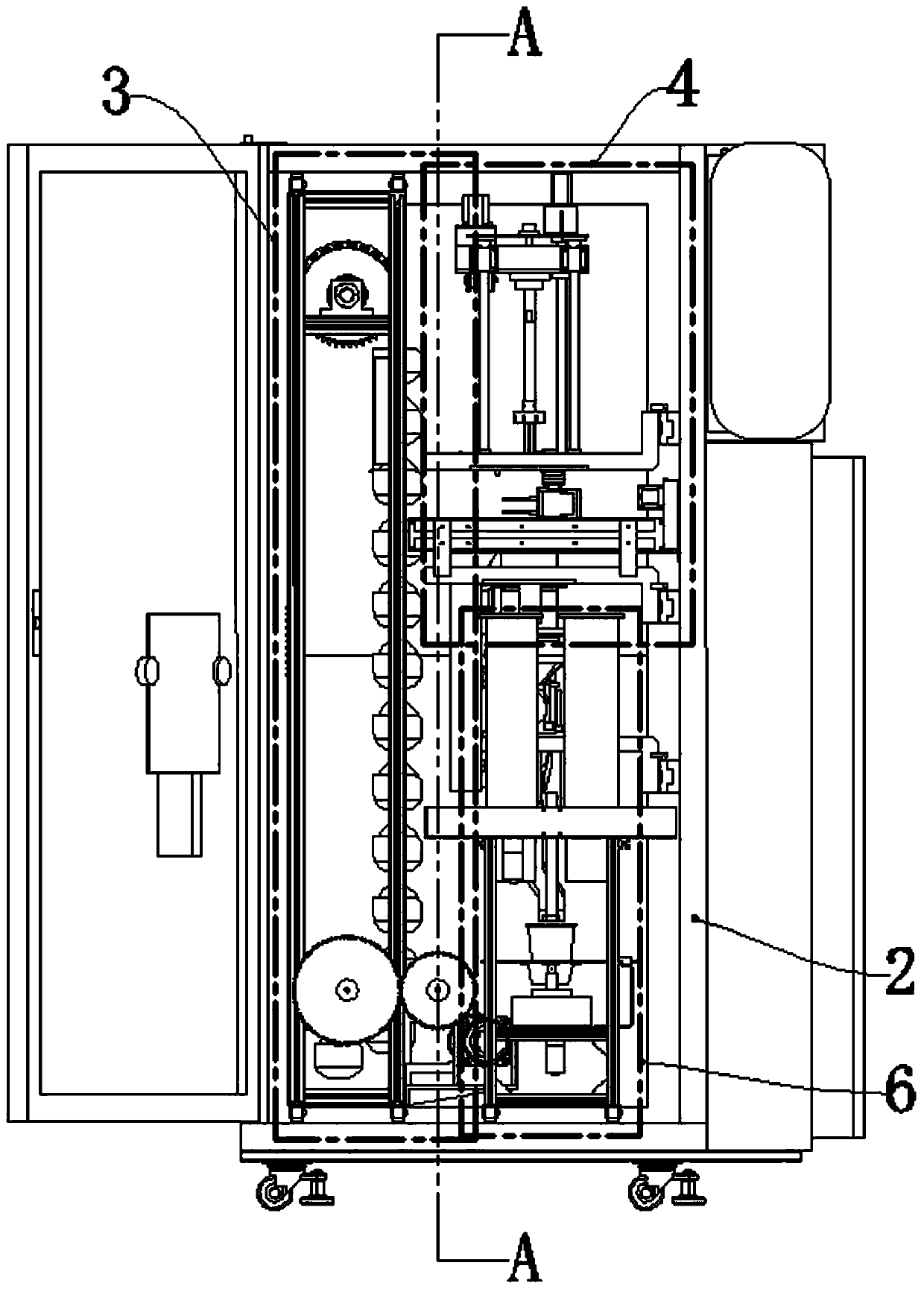

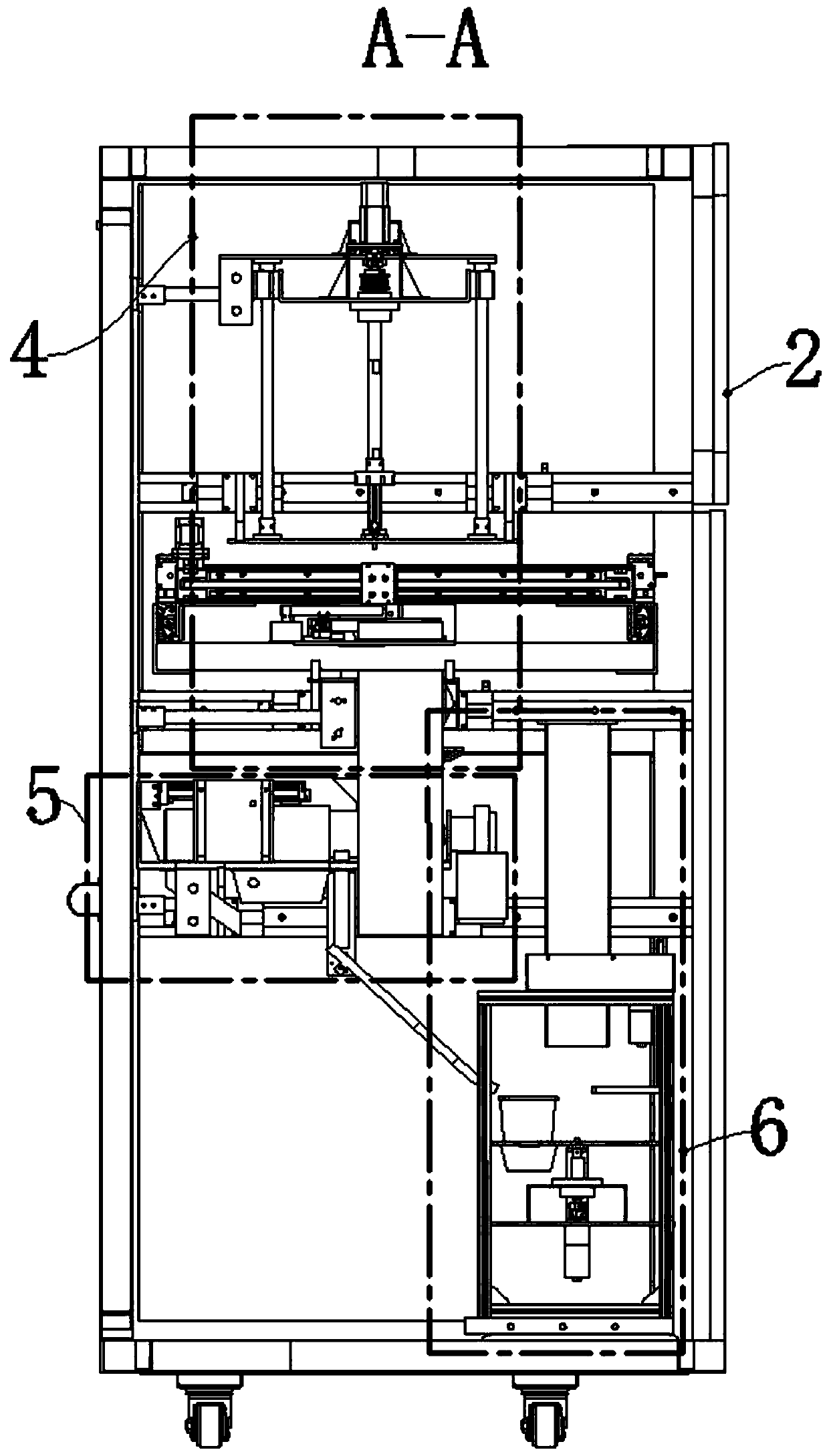

[0039] like Figure 1 to Figure 19 As shown, a freshly squeezed fruit juice vending machine includes a refrigerator 2 and a fruit storage mechanism 3 located in the refrigerator 2 , a juice pretreatment system 4 , a screw juicer mechanism 5 and a cup drop and cover mechanism 6 .

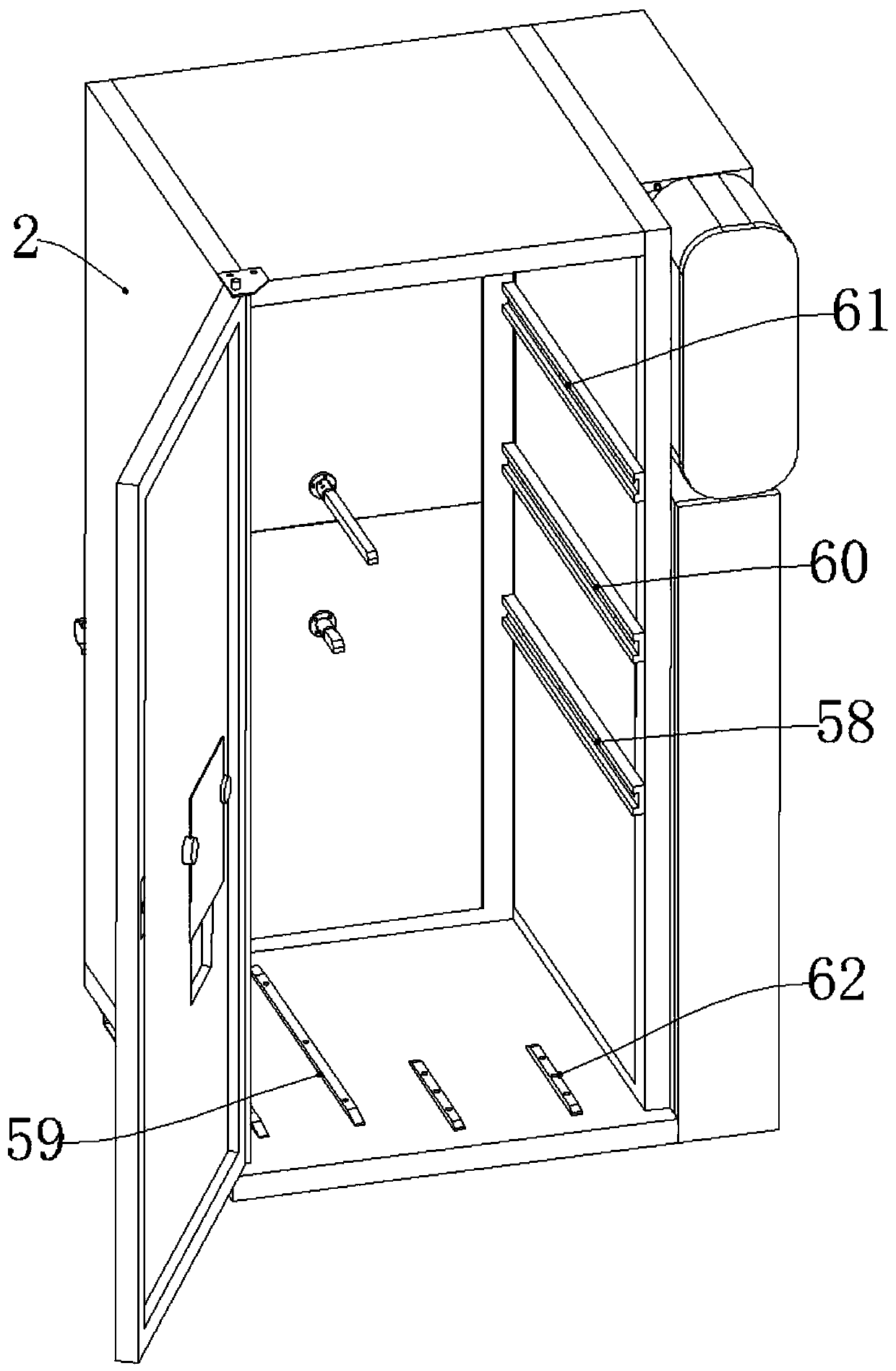

[0040] Fruit storage mechanism 3 comprises second support 18, fruit basket 19 and fruit basket elevating mechanism. like image 3 , Figure 4 As shown, the top surface and the bottom surface of the inner wall of the refrigerator 2 are fixedly installed with a first slide rail 58 arranged along the front and rear direction, and the first bracket 7 is provided with a first slider 63 matching the first slide rail 58, and the first bracket 7 is installed in the refrigerator 2 through the first slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com