High-altitude high-toughness tear-resistant cable and production process thereof

A tear-resistant, high-toughness technology, used in power cables for overhead applications, used to reduce the size of conductors/cables, power cables, etc., can solve the problem of poor toughness and tear resistance of cables, affecting cables Service life, cable damage and other problems, to achieve the effect of enhancing the connection effect, prolonging the service life, and enhancing the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

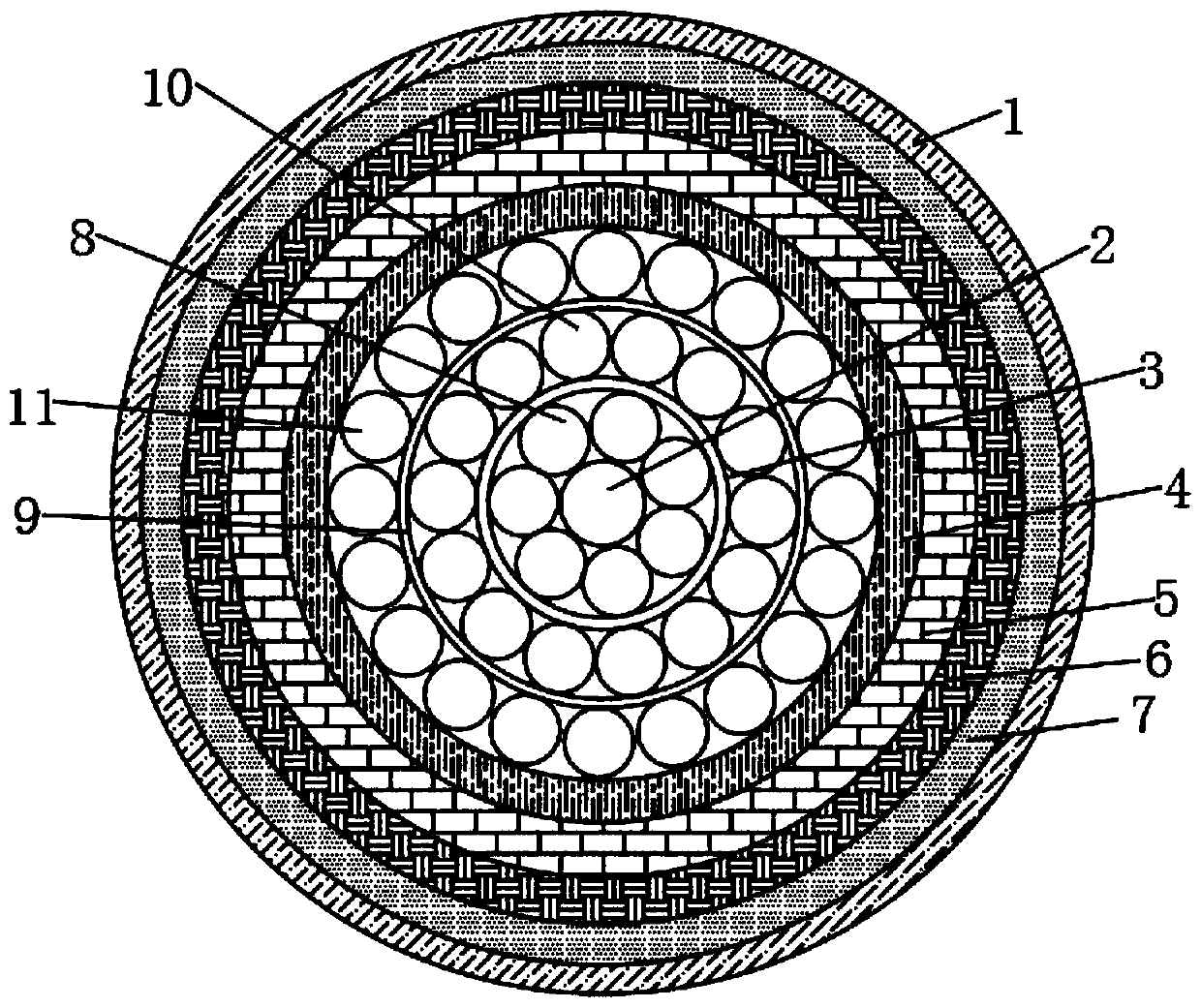

[0026] refer to figure 1 , a high toughness tear-resistant cable for high altitude, the inner ring of the first layer guide core 8 is abutted with the traction core 2, and the traction core 2 is made of steel wire, including the first layer guide core 8, the first layer guide core 8 The outer side is wrapped with a first wrapping layer 3, and a second layer of guide core 10 is arranged outside the first wrapping layer 3, and a second wrapping layer 9 is wrapped outside the second layer of guide core 10, and a third layer is arranged outside the second wrapping layer 9. The guide core 11, the third layer of guide core 11 is wrapped with an insulating layer 4, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com