A kind of processing method of preserved orange peel by suppressing non-enzymatic browning by high-pressure carbon dioxide

A technology of high-pressure carbon dioxide and processing methods, which is applied in the confectionery industry, the function of food ingredients, and gas-containing food ingredients, etc., to achieve the effects of maintaining nutritional components and sensory quality, inhibiting browning, and improving color and luster quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Soak and wash the reaction kettle with a sterilizing solution (such as chlorine dioxide), and then rinse the reaction kettle with distilled water for later use. The navel orange used in the experiment was Yichang Lunwan navel orange. Commercially purchased oranges are washed, peeled, and cut into pieces for later use.

[0022] (1) High-pressure carbon dioxide treatment: put the orange peel pieces in an open container, put them into the reactor, seal the reactor, and then fill the reactor with carbon dioxide until the pressure in the reactor rises to 9MPa, and keep the pressure for 20min , while controlling the temperature in the kettle at 30°C. After processing, open the valve to quickly relieve the pressure, release carbon dioxide, and take out the orange peel.

[0023] (2) Orange peel candy: boil the orange peel with 50% sucrose solution for 5 minutes, stop heating and then continue to soak for 12 hours. Take out the orange peel pieces, drain and bake in an oven at...

Embodiment 2

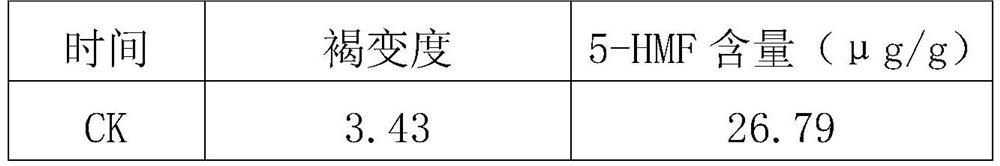

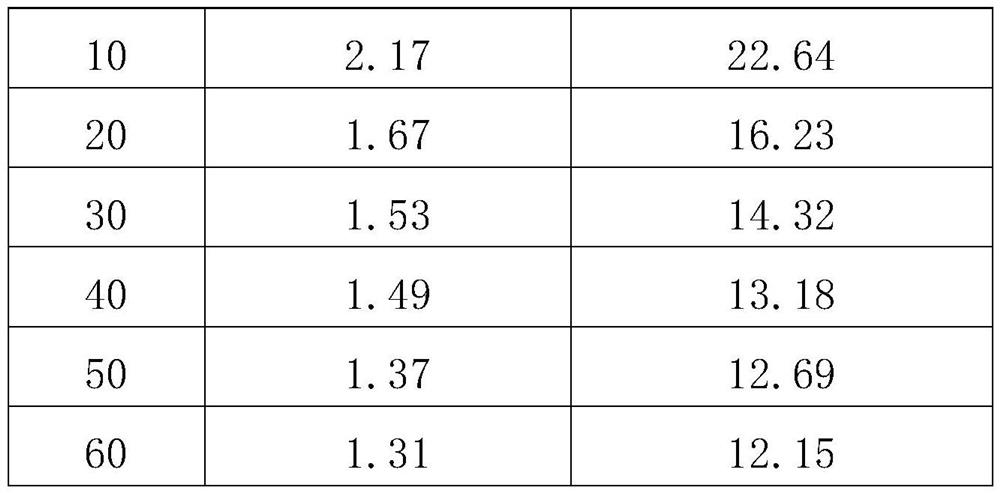

[0025] Effects of pressure, holding time and temperature on orange peel browning degree and 5-HMF content:

[0026] Set the pressure in the kettle to 3, 6, 9, 12, 15, 18Mpa, the temperature to 25, 30, 35, 40, 45, 50°C, and the holding time to 10, 20, 30, 40, 50, 60min, Preserved orange peel was prepared according to the method of Example 1. The dried orange peel was sampled, and a spectrophotometer was used to measure the relative browning degree of the orange peel at 420 nm, and the HPLC method was used to measure the 5-HMF content in the preserved fruit. The preserved orange peel prepared without high-pressure carbon dioxide treatment was used as a control, and the results are shown in Table 1-3.

[0027] Table 1 Effect of pressure on orange peel browning degree and 5-HMF content

[0028] pressure Browning degree 5-HMF content (μg / g) CK 3.43 26.79 3 2.72 24.32 6 2.39 21.67 9 1.67 16.23 12 1.51 15.59 15 1.38 14.11 18 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com