Vacuum deoxygenation nitrogenization blanching method for agaricus bisporus

A technology of vacuum deoxygenation and Agaricus bisporus is applied in the direction of food preservation, fruit and vegetable preservation, heating preservation of fruits/vegetables, etc., to achieve the effect of inhibiting non-enzymatic browning, simple operation and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

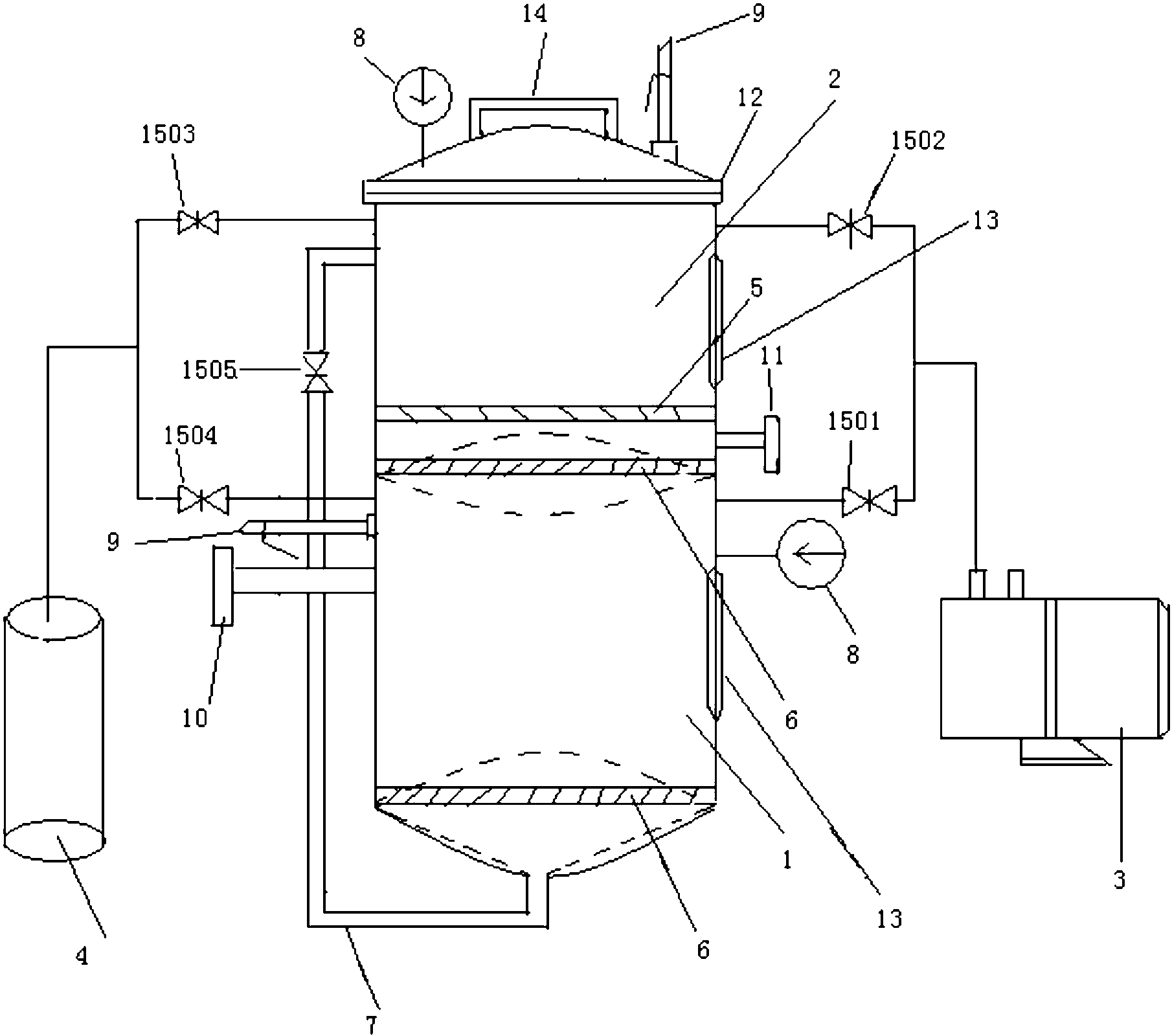

[0029] Such as figure 1 The deoxygenated and nitrogen-charged blanching equipment for fruits and vegetables includes a columnar blanching tank, a vacuum pump 3, and a nitrogen cylinder 4. The blanching tank is equipped with a perforated partition 5 to naturally divide it into upper and lower chambers. The blanching tank II chamber 2 is on top, and the two chambers are connected by a connecting pipe 7. The bottom of the blanching tank I chamber 1 is an inverted cone with a cone angle of 140-160°, and its connection with the connecting pipe 7 is at Cone top angle; the connecting part of the blanching tank II room 2 and the connecting pipe 7 is in the upper part, and the bottoms of the blanching tank I room 1 and II room 2 are respectively equipped with electric heating tubes (or heating steam coils) 6 and the blanching tank The electric heating tube (or heating steam coil) 6 of Room II 2 is set 10 cm below the perforated partition 5. Room 1 of the blanching tank is provided with...

Embodiment 2

[0037] Vacuumize the blanching liquid to 0.08MPa and keep for 5min; vacuumize the water-controlled Agaricus bisporus to 0.08MPa and keep for 5min; the blanching time is 10min, and the others are the same as in Example 1.

Embodiment 3

[0039] Vacuumize the blanching solution to 0.09MPa and keep for 4min; vacuumize the water-controlled Agaricus bisporus to 0.09MPa and keep for 4min; the blanching time is 7min, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com