An improved bag filter

A bag filter and an improved technology are applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, which can solve the problems of reduced air filtration efficiency, insufficient convenience, energy saving and environmental protection, etc., and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

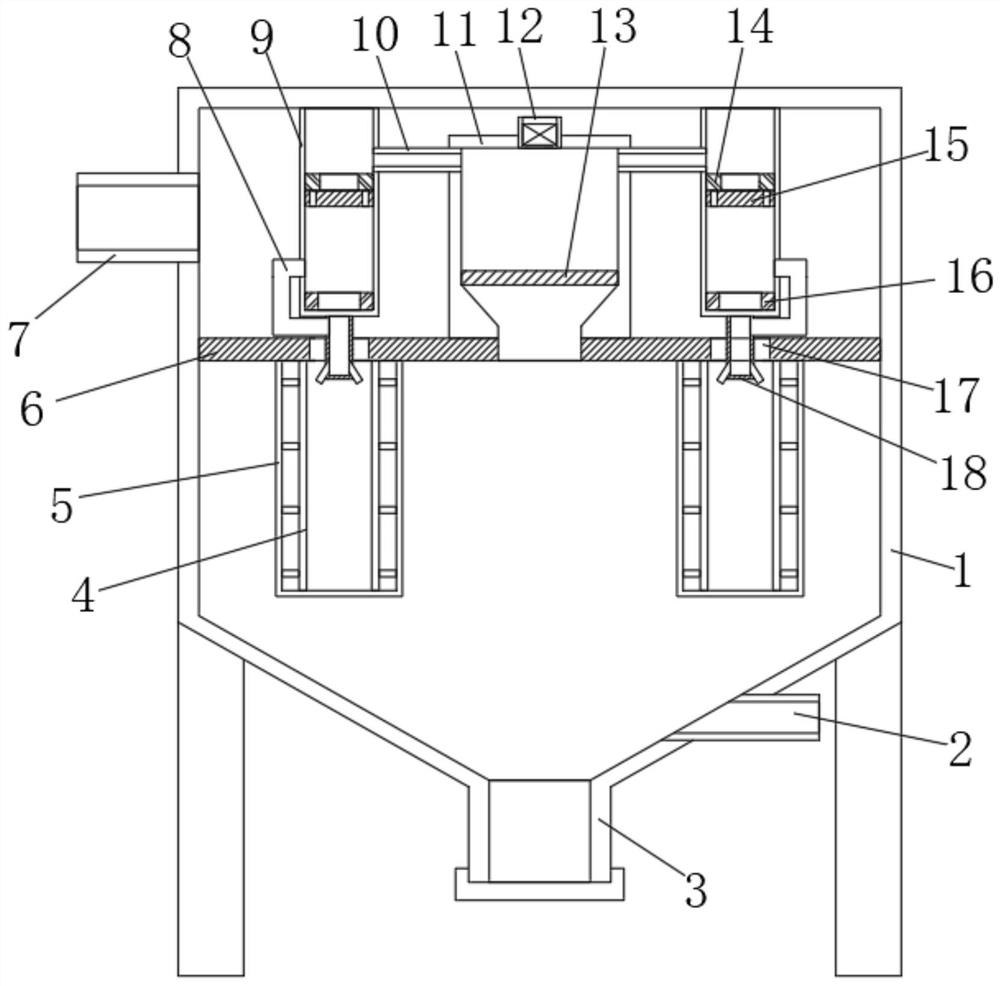

[0021] refer to figure 1 , an improved bag filter, including a housing 1 and an air inlet 2 and an air outlet 7 connected to the housing 1. The lower end of the housing 1 is provided with an ash hopper 3, and the inside of the housing 1 is fixedly connected with a horizontal The partition 6 is provided, and the partition 6 divides the interior of the housing 1 into an air outlet chamber and an air filter chamber arranged up and down. The inlet port 2 and the outlet port 7 communicate with the air filter chamber and the air outlet chamber respectively, and the upper end of the partition 6 is fixedly connected. There is a pressure storage mechanism, and the upper end surface of the partition 6 is provided with a plurality of vents 17 at equal intervals along its circumference, and the lower end surface of the partition 6 is fixedly connected with a plurality of fixing frames corresponding to the positions of the vents 17 at equal intervals along its circumference. 4. A filter ba...

Embodiment 2

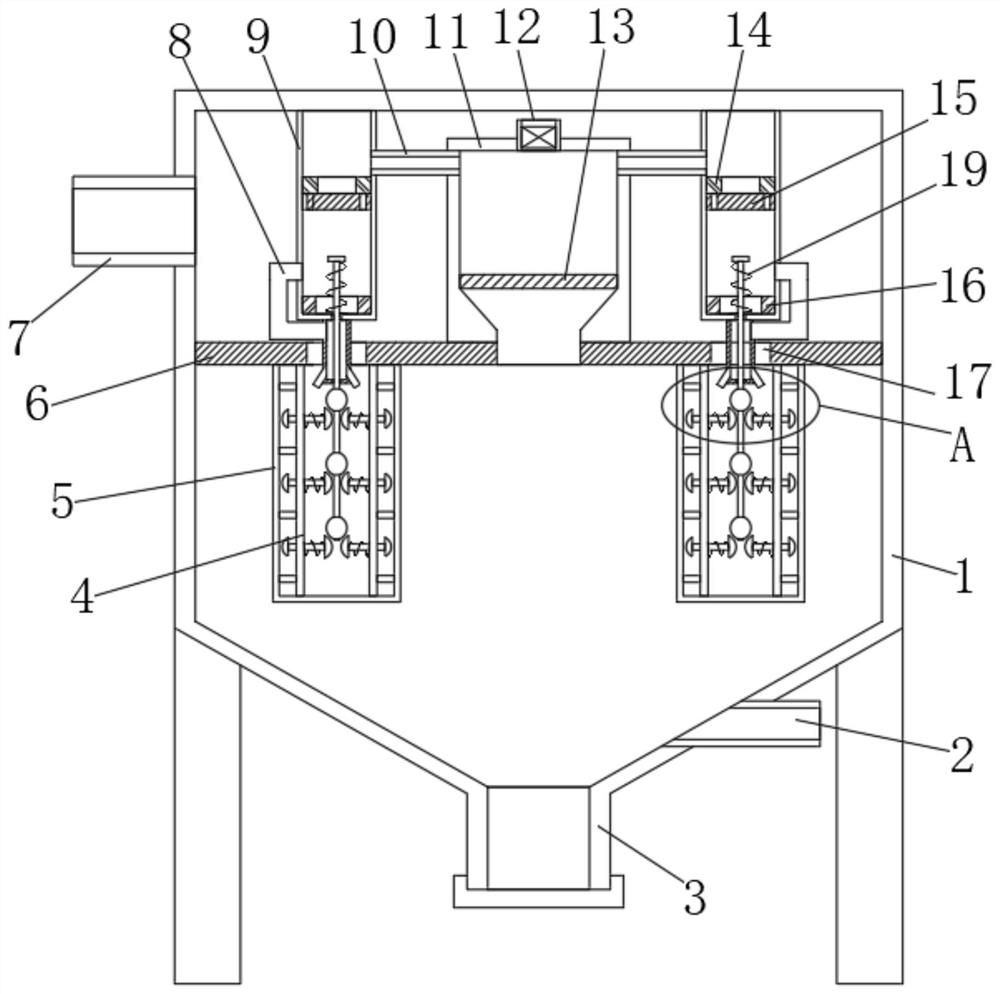

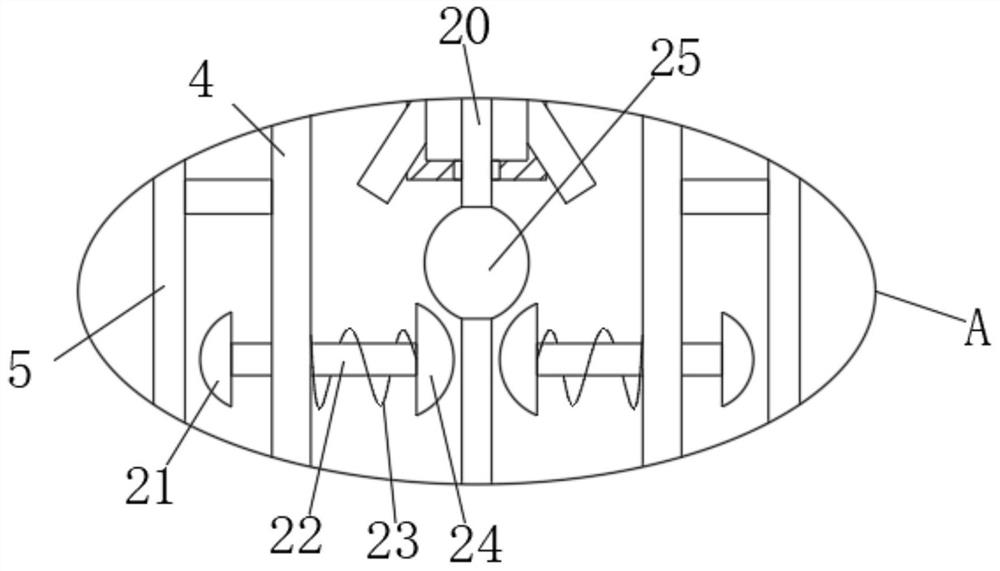

[0027] refer to Figure 2-3 The difference between embodiment two and embodiment one is that a toggle mechanism is provided in the fixed frame 4 of this embodiment, and the toggle mechanism includes a movable rod 20 vertically arranged on the inner side of the fixed frame 4, and the upper end of the movable rod 20 is sequentially Through the air injection pipe 18, the first fixed cylinder 9 and extend to the inner side of the first fixed cylinder 9, the upper end of the movable rod 20 is fixedly connected with the limit block, and the movable rod 20 is located on the side wall of the first fixed cylinder 9 and is sleeved with a first Spring 19, the two ends of the first spring 19 are respectively fixedly connected on the limit block, the inner bottom wall of the first fixed cylinder 9, and the movable rod 20 is positioned on the side wall in the fixed frame 4 and is fixedly sleeved with a plurality of fixed parts at equal intervals. The ball 25 is equipped with a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com