Hot wire consumable electrode gas-shielded welding device

A technology for melting electrode gas and shielding welding, which is used in devices for supplying/removing shielding gas, electrode support devices, and devices for supporting electrode clips, etc. problem, to achieve the effect of small interference and arc interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

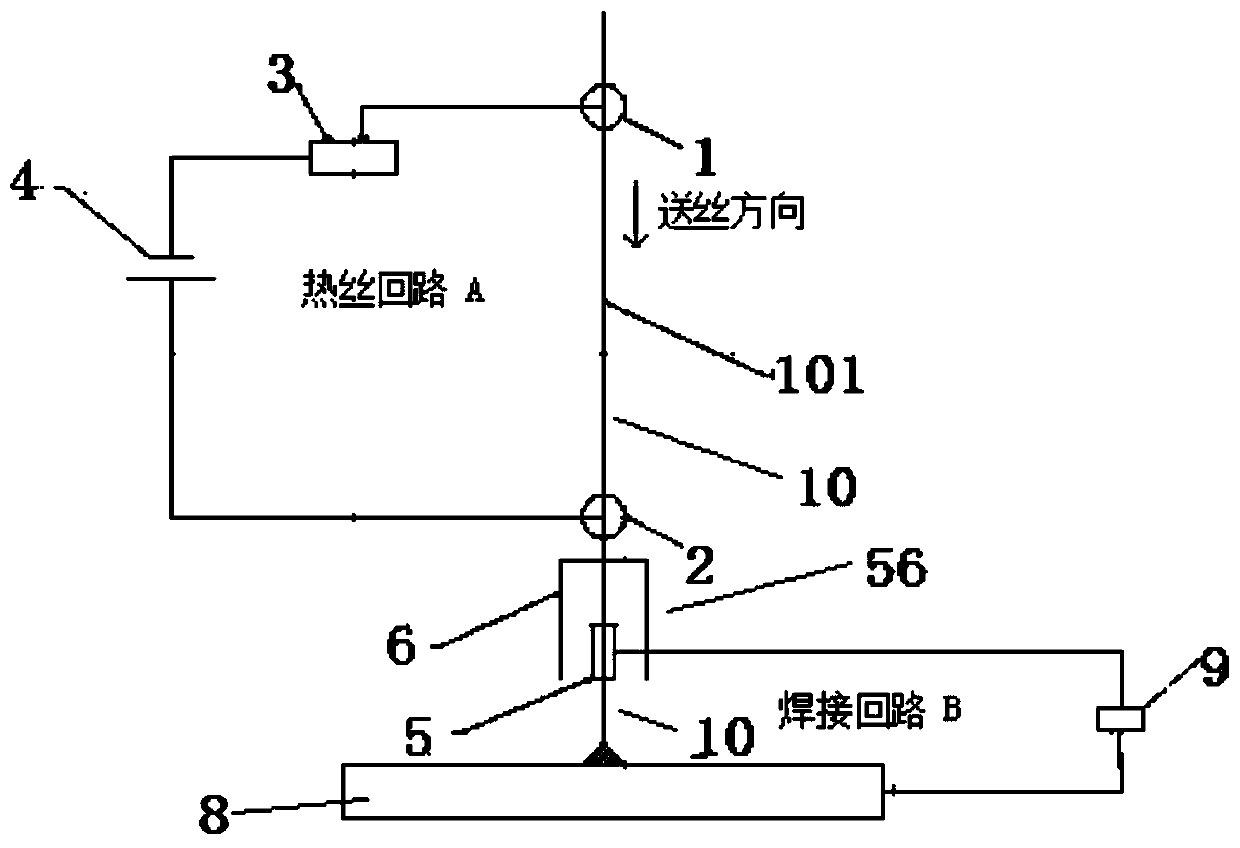

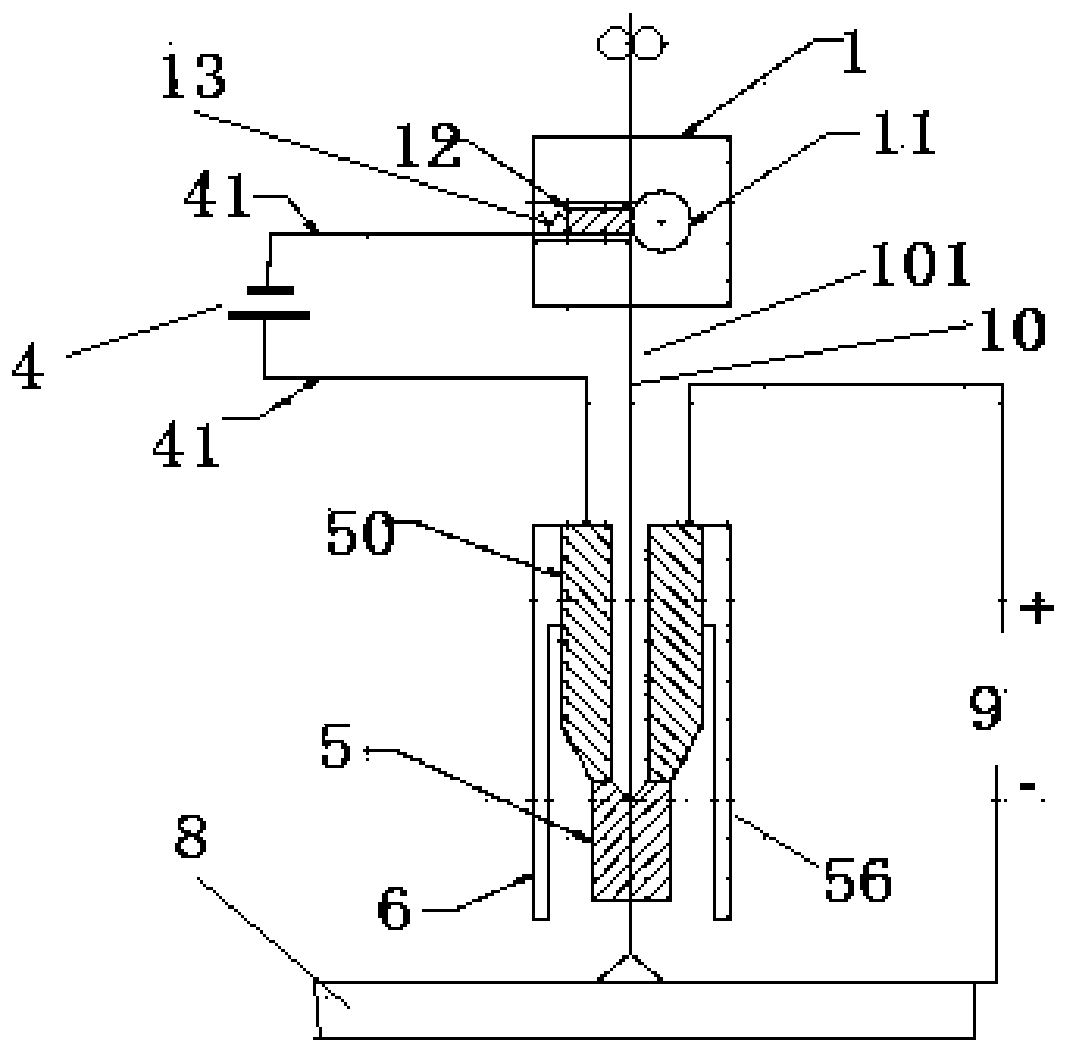

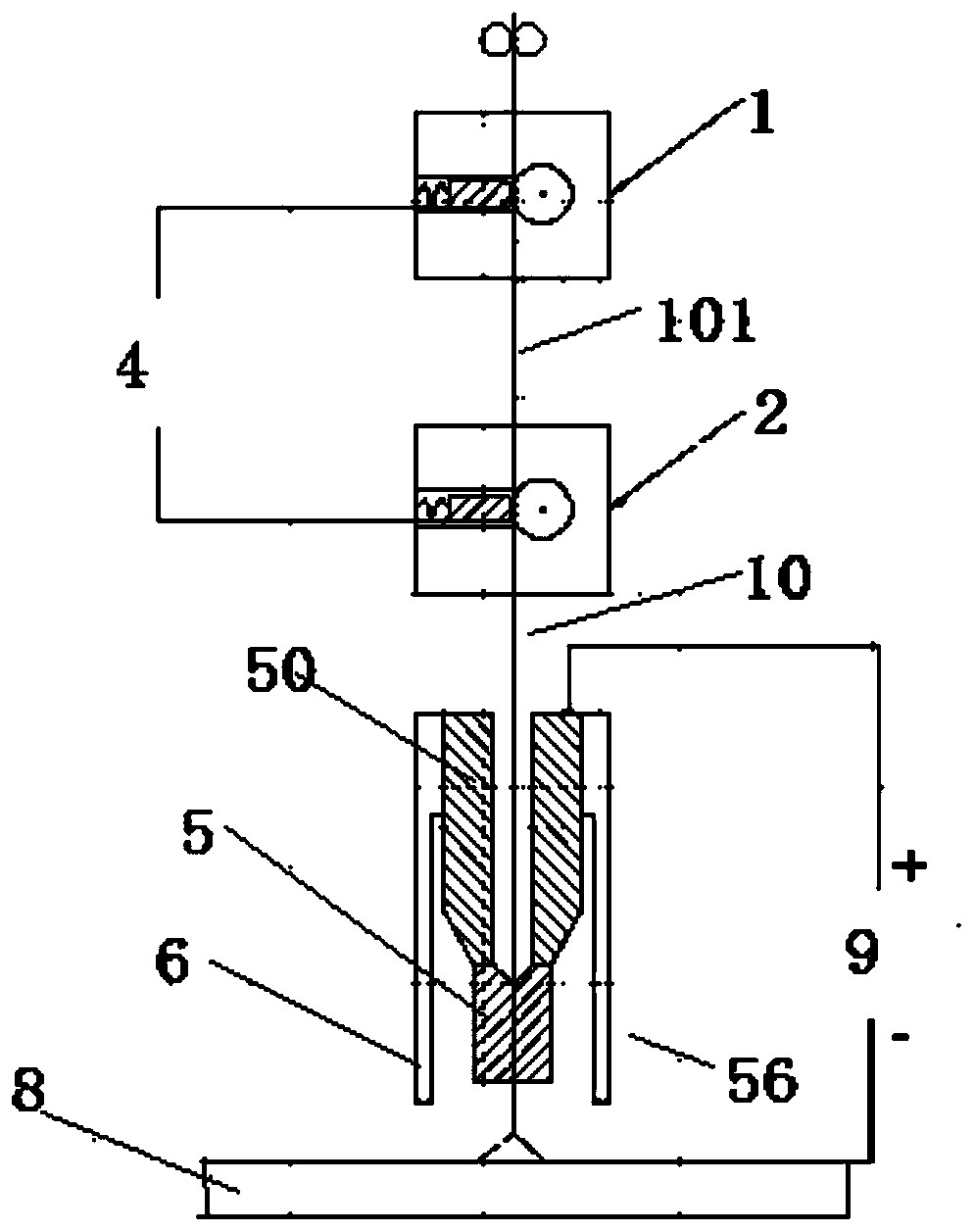

[0025] see figure 1 , A hot wire MIG shielded welding device of the present invention includes a welding power source 9 , a welding torch 56 , and a welding wire power source 4 . One end of the welding power source is connected to the workpiece 8 and the other end is connected to the conductive tip 5 of the welding torch 56 to form a welding circuit B. The conductive wire 10 is fed by a wire feeding device (not shown in the figure), and its end is clamped by the conductive tip 5 of the welding torch 56 . One end of the welding wire power supply 4 is electrically connected to the welding wire 10 that does not enter the welding torch 56 through a conductive joint 1, and the other end is electrically connected to the conductive tip 5 of the welding torch 56 or its relevant parts (for example, the conductive seat 50, see appendix figure 2 ) connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com