Press blade device of gel mask machine

A knife device and mask technology, applied in metal processing, etc., can solve the problems of incomplete waste discharge, high product error rate, energy consumption, etc., and achieve the effects of reducing energy use, ensuring collection efficiency, and improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

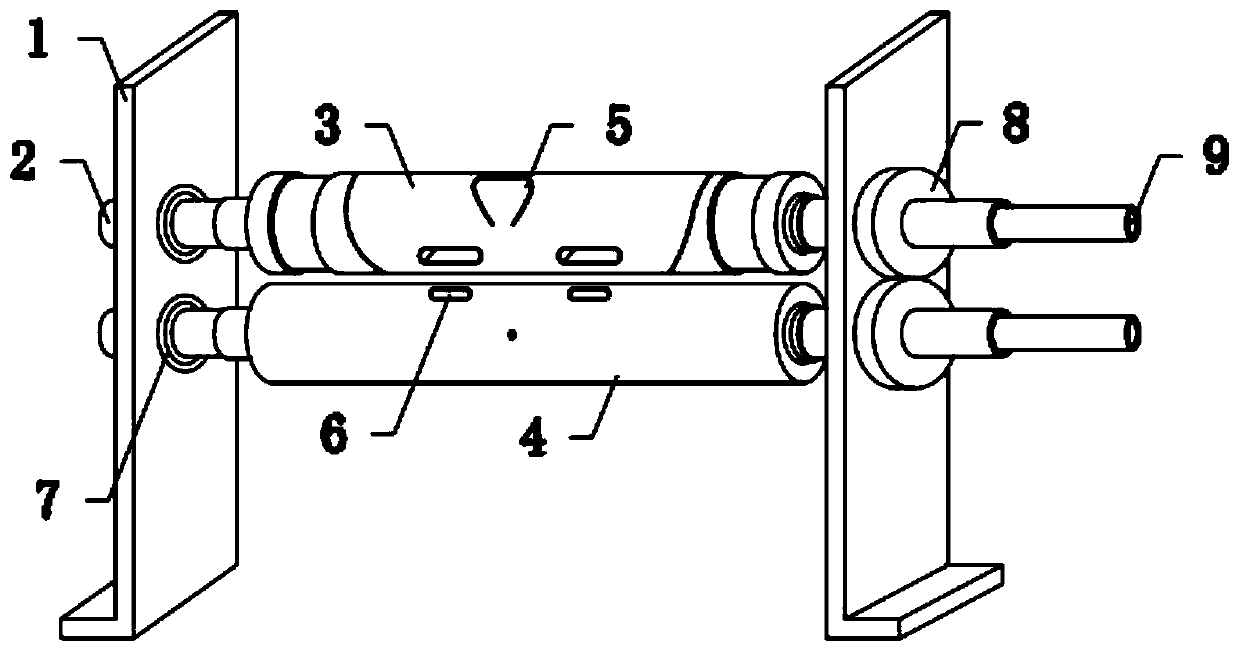

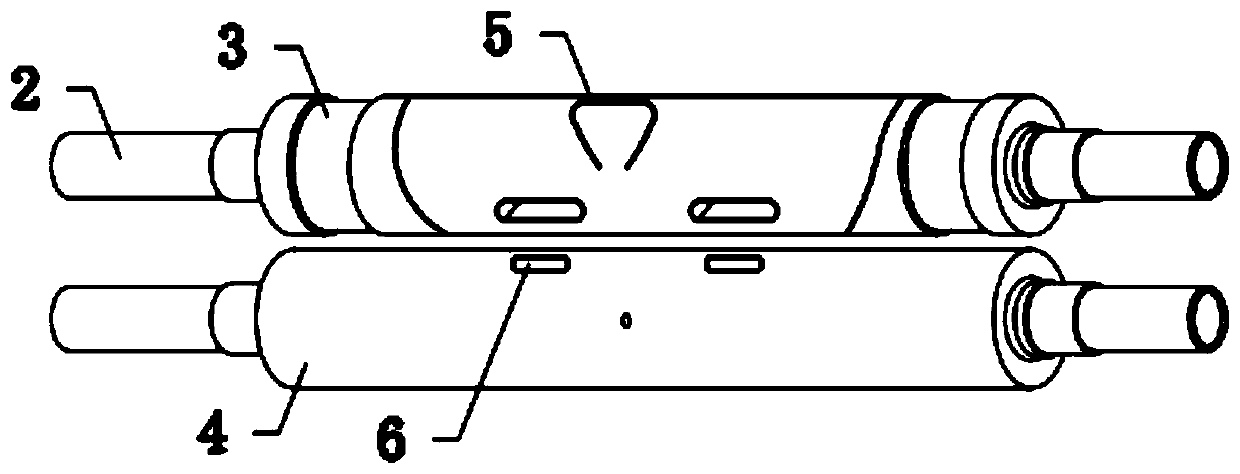

[0028] see Figure 1-2 , the present invention provides a kind of technical scheme: a kind of pressing knife device of gel facial mask machine, comprises the following structure:

[0029] The two axes are arranged parallel to the rotating rollers, and the two rotating rollers are the cutting rotating roller 3 and the supporting rotating roller 4 respectively. The cutting rotating roller 3 and the supporting rotating roller 4 are hollow, and one end of the supporting rotating roller 4 is closed and the other end is open. Or both ends are open. According to the needs of use, when one end is closed and the other end is open, a high-pressure air nozzle 9 is connected to the open end, and the instantaneous air pressure provided is relatively low. When there is only one high-pressure air nozzle 9 and the instantaneous When the air pressure is not enough to push the waste material into the cutting rotating roller 3, the two ends of the supporting rotating roller 4 are opened, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com