System for reducing air friction resistance on surfaces of train by blowing air to interfere in air flow

A technology that interferes with airflow and air friction. It is used in railway car body, fluid flow, climate sustainability and other directions. It can solve the problem that straight holes cannot be closed, and achieve the effect of reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

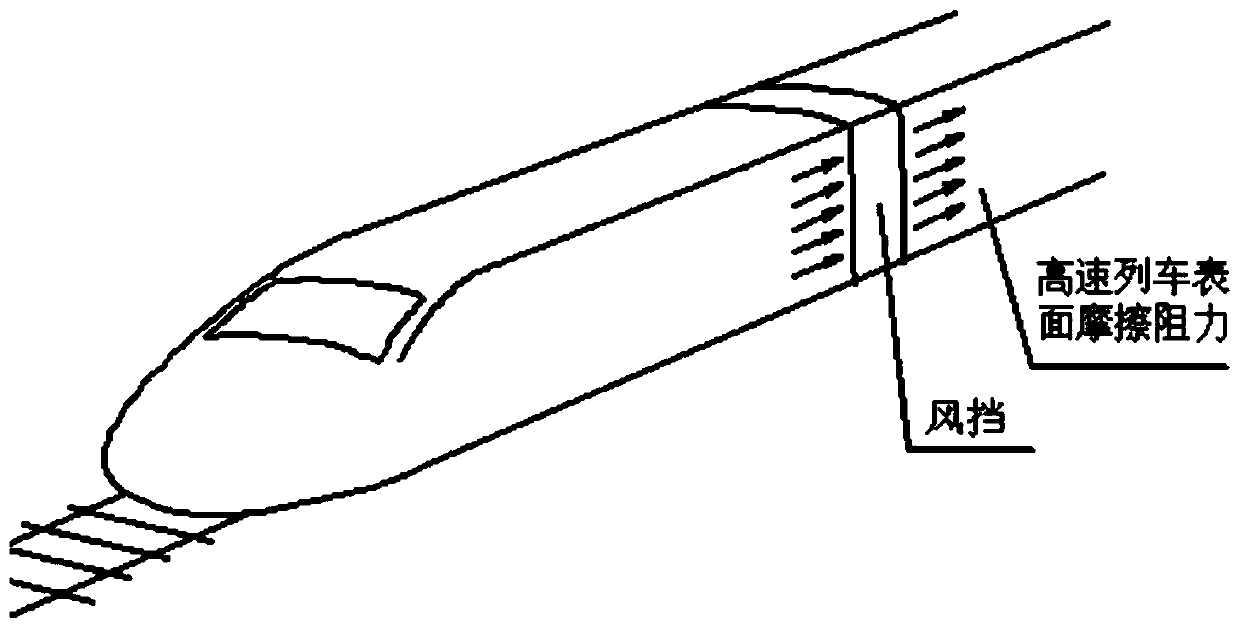

[0038] The invention provides a system for reducing the air friction resistance of the train surface by interfering with the air flow in a blowing manner.

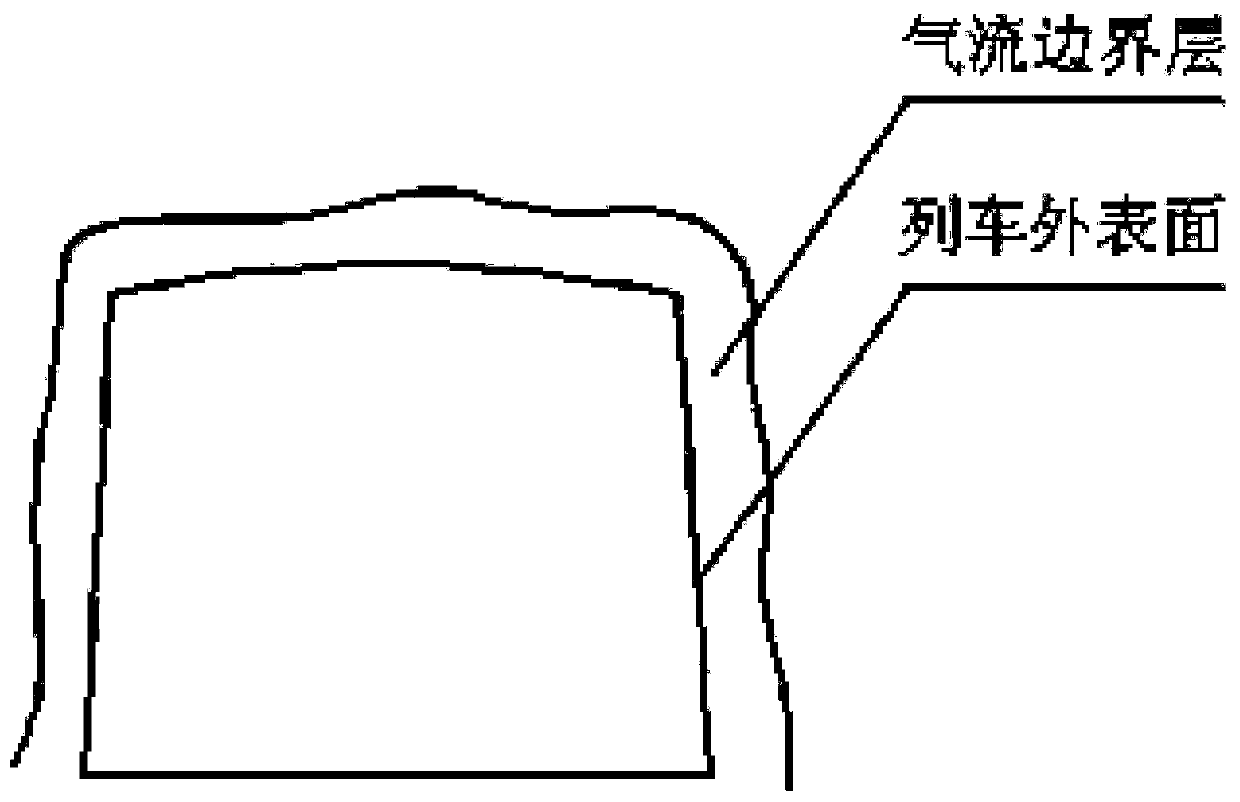

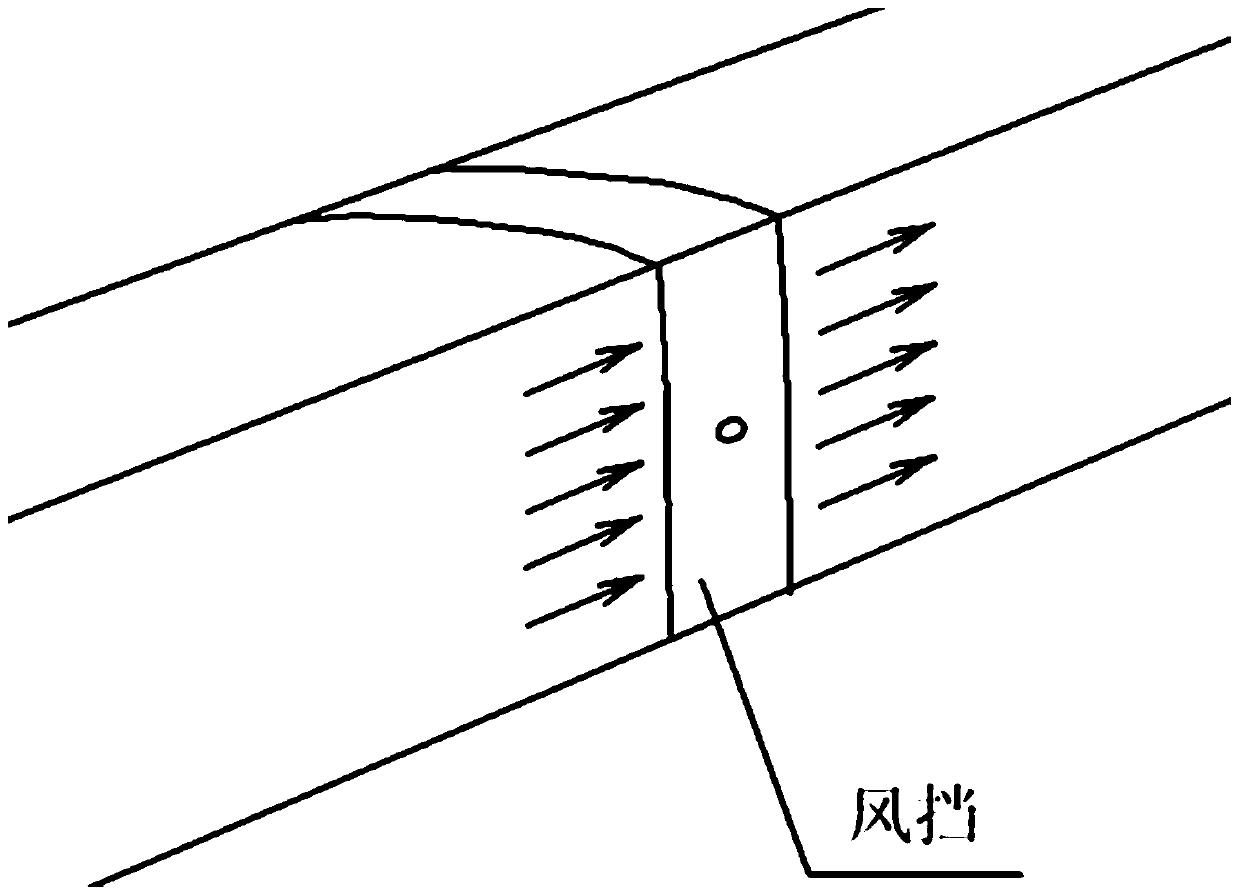

[0039] The blowing technology applied to high-speed trains should be able to blow when moving forward, and the direction is to blow to the side and rear to reduce frictional resistance. When the train is traveling in the reverse direction, the blowing holes will change to face the direction of travel. At this time, close the blow hole. In this way, on the outermost surface of the train, a convex-shaped surface is adopted. The blow hole can be opened behind the train in the forward direction, and the blow hole can be closed in front of the train. That is to say, in one direction, blowing is achieved, while blowing, the blowing holes on the surface of the car body can also be sealed; in the other direction, the blowing holes on the car body can be closed.

[0040] Specifically, the system of the present invention to interfere wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com