Intelligent unmanned loading system and method for stacked products

A product and intelligent technology, applied in lifting devices, object stacking, loading/unloading, etc., can solve problems such as skewed or scattered stacking, manual intervention in the loading process, and difficulty in unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

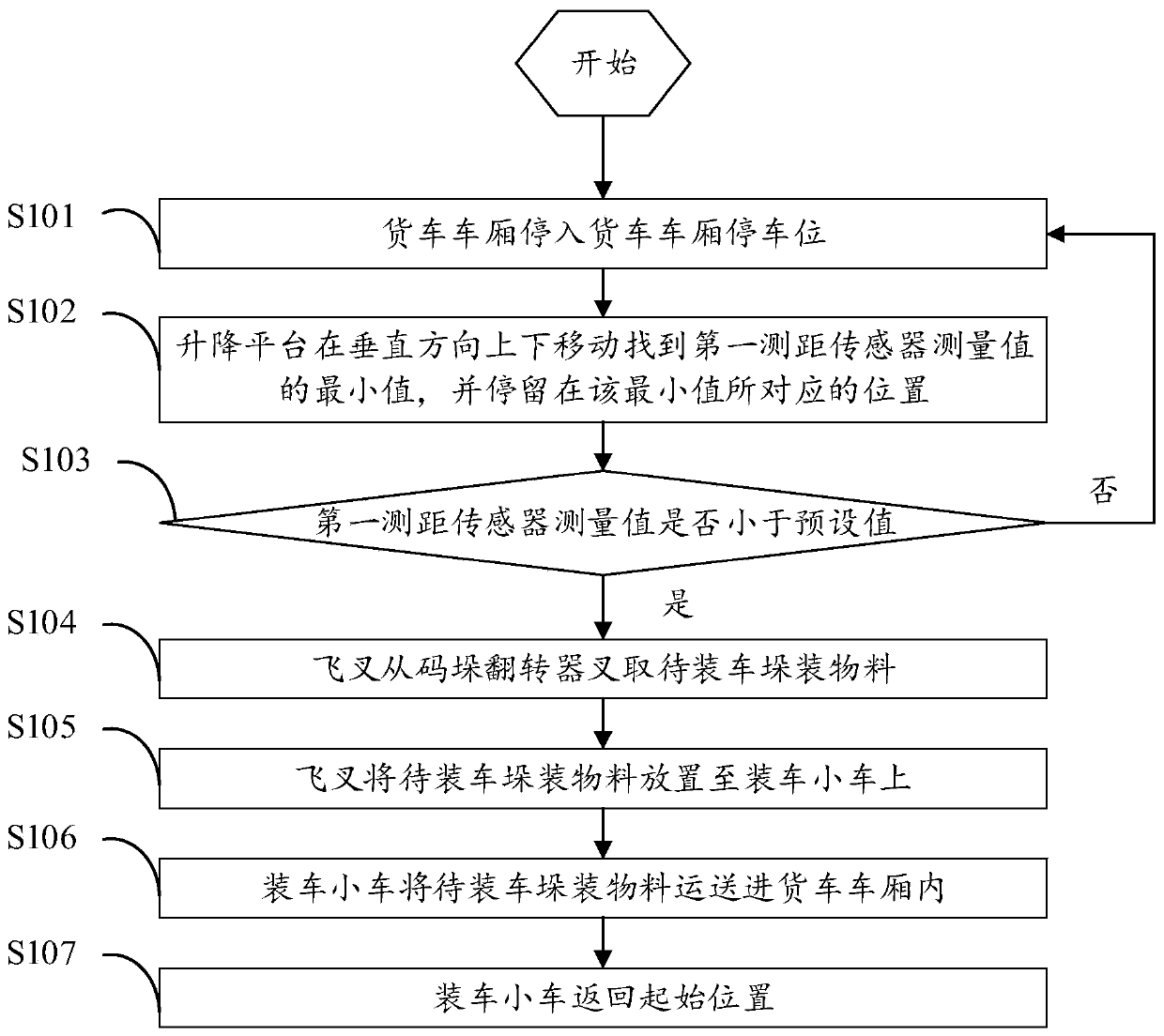

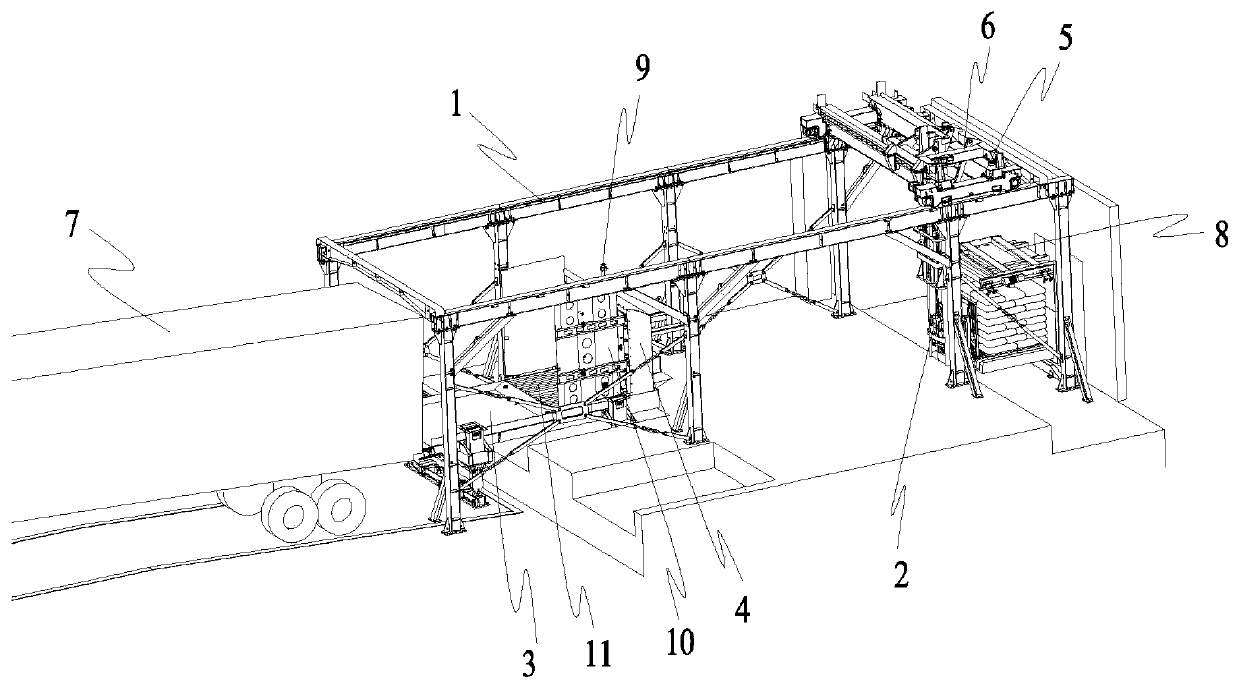

[0062] Such as Figure 1-2 As shown, an intelligent unmanned loading system for stacked products, the intelligent unmanned loading system for stacked products includes:

[0063] Track support 1, flying fork 2, lifting platform 3, loading trolley 4, control module;

[0064] The upper end of the track support 1 is provided with a first driving track, on which a first bridge crane is slidably installed, and a second driving track is installed on the first bridge driving vehicle 5, and on the second driving rail A second bridge-type traveling vehicle 6 is slidably installed, and the direction of the second driving track is perpendicular to the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com