Full-automatic deviation correcting mechanism of printing machine

A printing machine, fully automatic technology, applied in the field of deviation correction mechanism, can solve the problems of high work intensity, low printing machine work efficiency, heavy workload, etc., and achieve the effect of stable structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

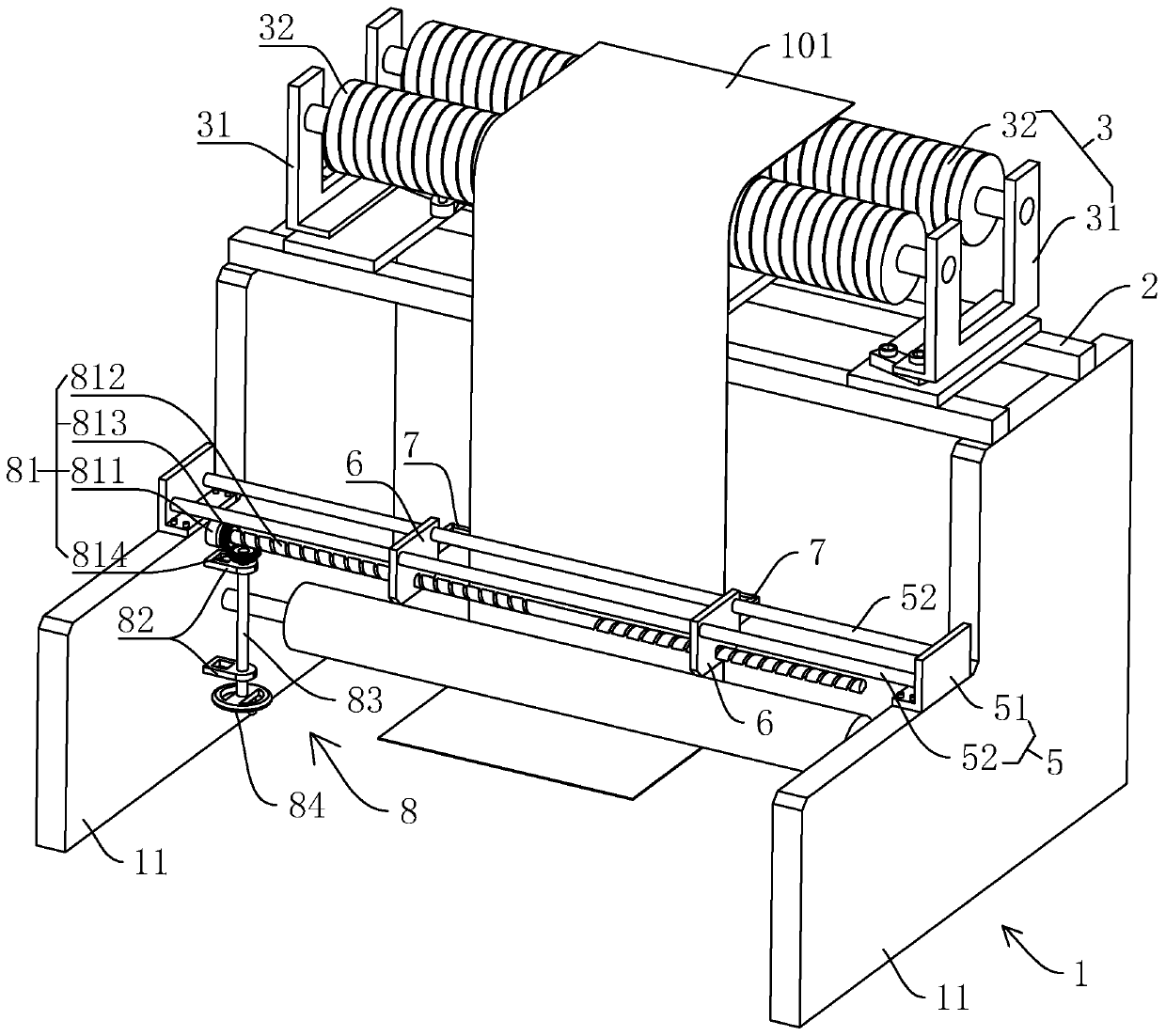

[0041] refer to figure 1 and figure 2 , is a deviation correction mechanism of a fully automatic printing machine disclosed in the present invention, comprising: a frame 1, a horizontal support frame 2, a deviation correction roller group 3, a deviation correction driver 4, a horizontal guide 5, a sliding plate 6, and a U-shaped photoelectric sensor 7. Manually synchronizing the driving part 8 and the control module (in this embodiment, it is specifically referred to as controlling the PLC and the computer, and is not specifically shown in the drawings).

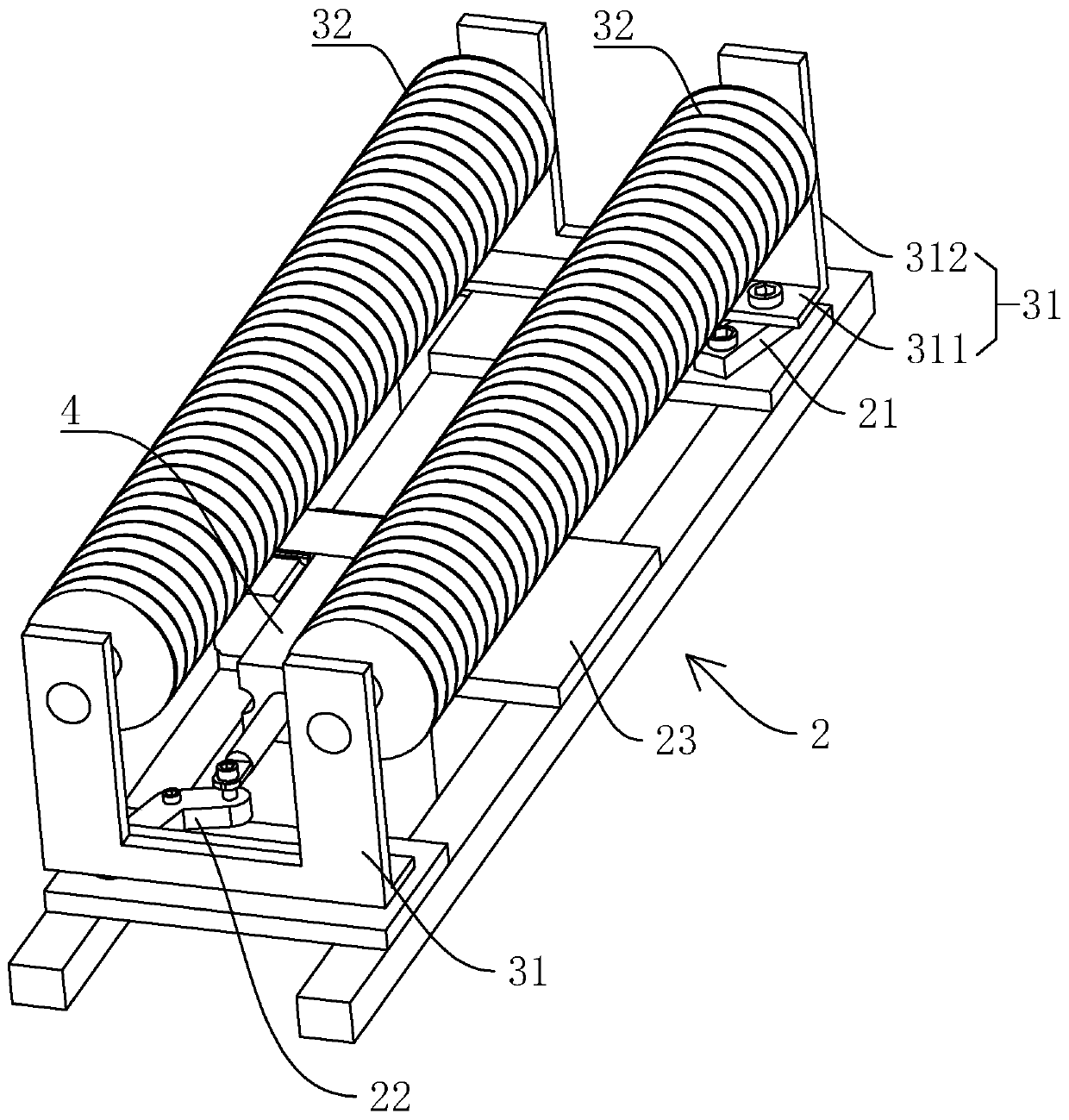

[0042] The frame 1 is composed of two side plates 11 arranged in parallel and at intervals. In other implementations, support rods can be added between the two side plates 11 to enhance the structural strength of the entire frame 1. The horizontal support frame 2 is fixed on two Between the side plates 11, the deviation-correcting roller group 3 is movably connected to the horizontal support frame 2, and the deviation-corr...

Embodiment 2

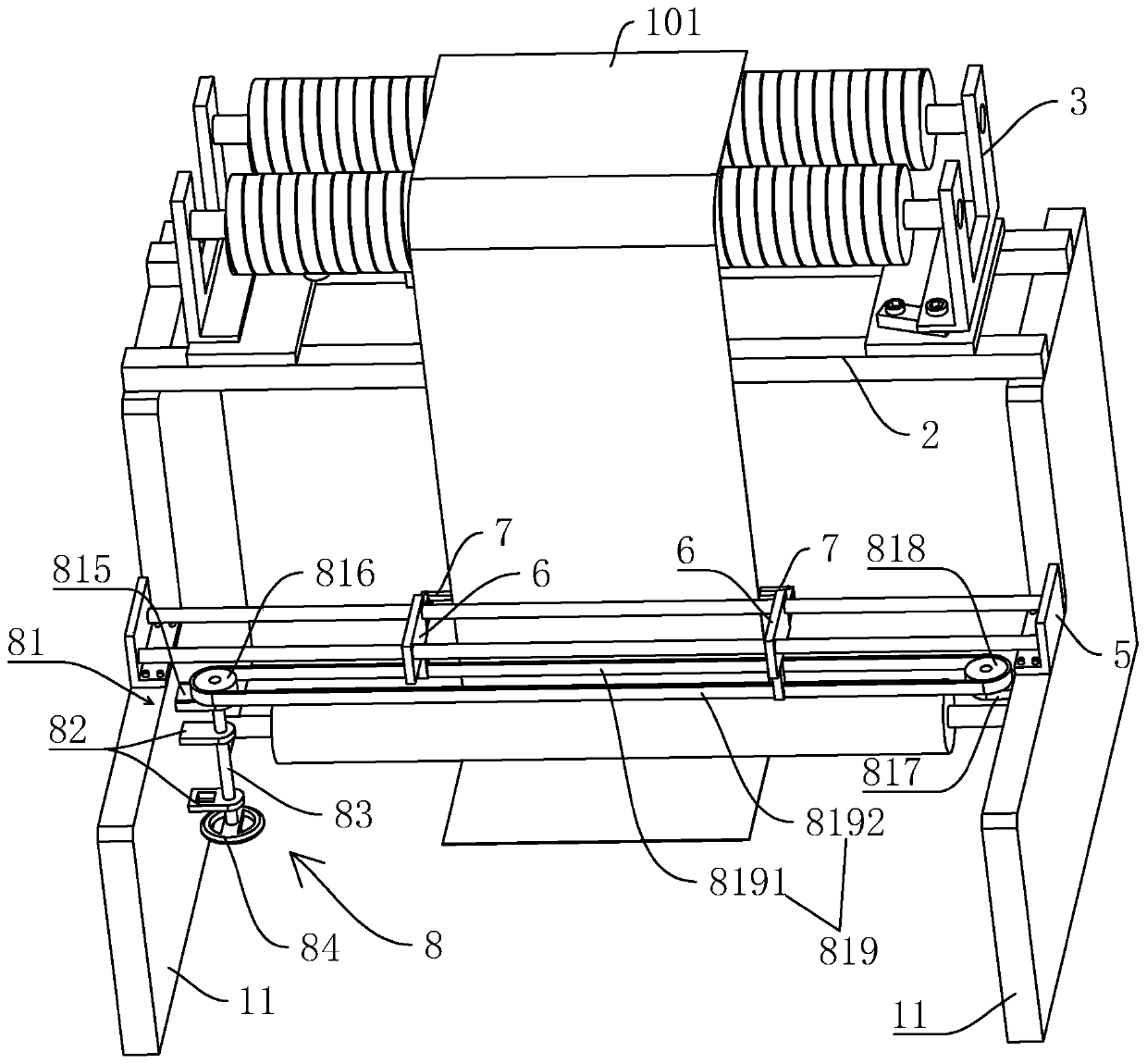

[0057] refer to image 3, is a deviation correction mechanism of a fully automatic printing machine disclosed in the present invention. The difference from Embodiment 1 is that the transmission member 81 includes: a first bracket 815, a driving pulley 816, a second bracket 817, and a driven pulley 818 and synchronous belt 819; the first bracket 815 is fixed on the inner wall of the side plate 11, the driving pulley 816 is rotatably assembled on the first bracket 815, the vertical rotation rod 83 drives the driving pulley 816 to rotate, and the second bracket 817 is fixed on the other side On the inner wall of the side plate 11, the driven pulley 818 is rotatably mounted on the second bracket 817, the timing belt 819 is sleeved between the driving pulley 816 and the driven pulley 818, and the driving pulley 816, the driven pulley 818 The rotation axes are arranged vertically; one sliding plate 6 is fixed to the first part 8191 of the synchronous belt 819, and the other sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com