Forming mold and preparation technology for laminated solid propellant

A solid propellant, forming mold technology, applied in attack equipment, explosives processing equipment, generation of compressed gas, etc. bubbles and other problems, to save production time, improve production efficiency, and make the preparation process easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

[0031] This embodiment is a laminated solid propellant forming mold and its preparation process.

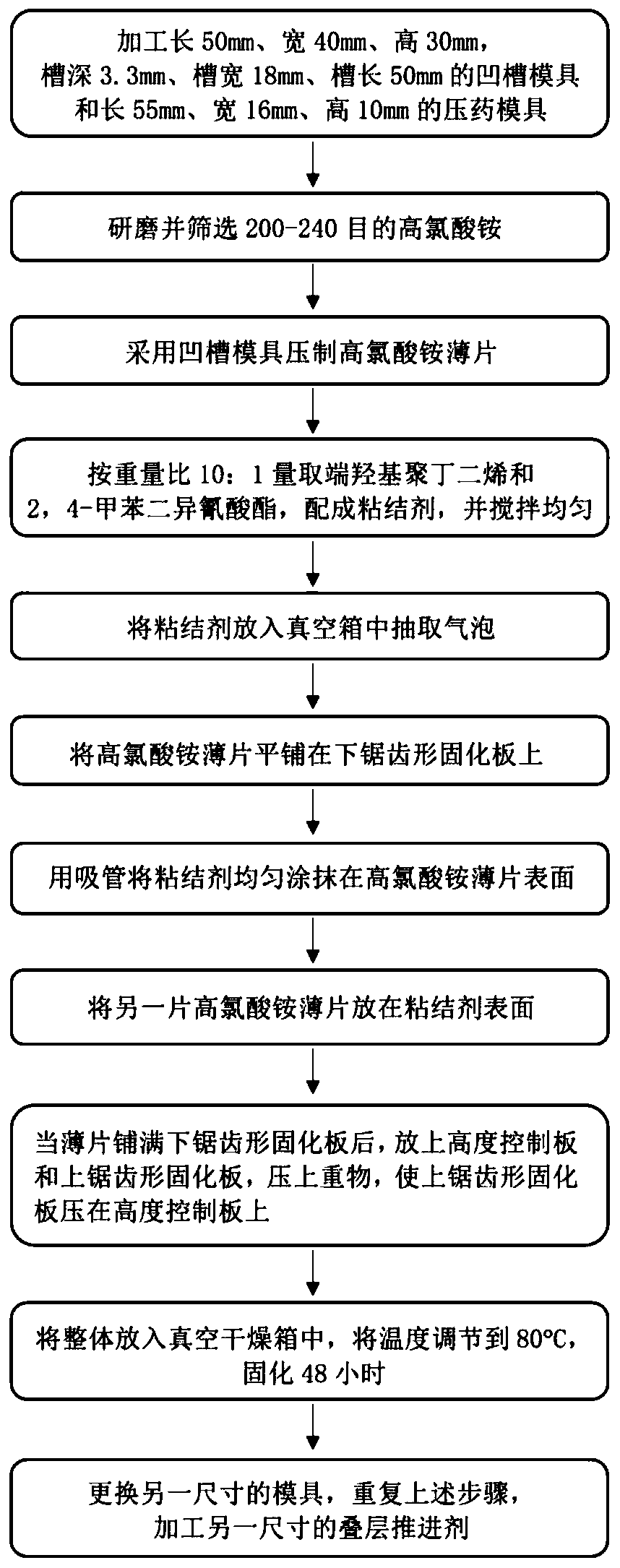

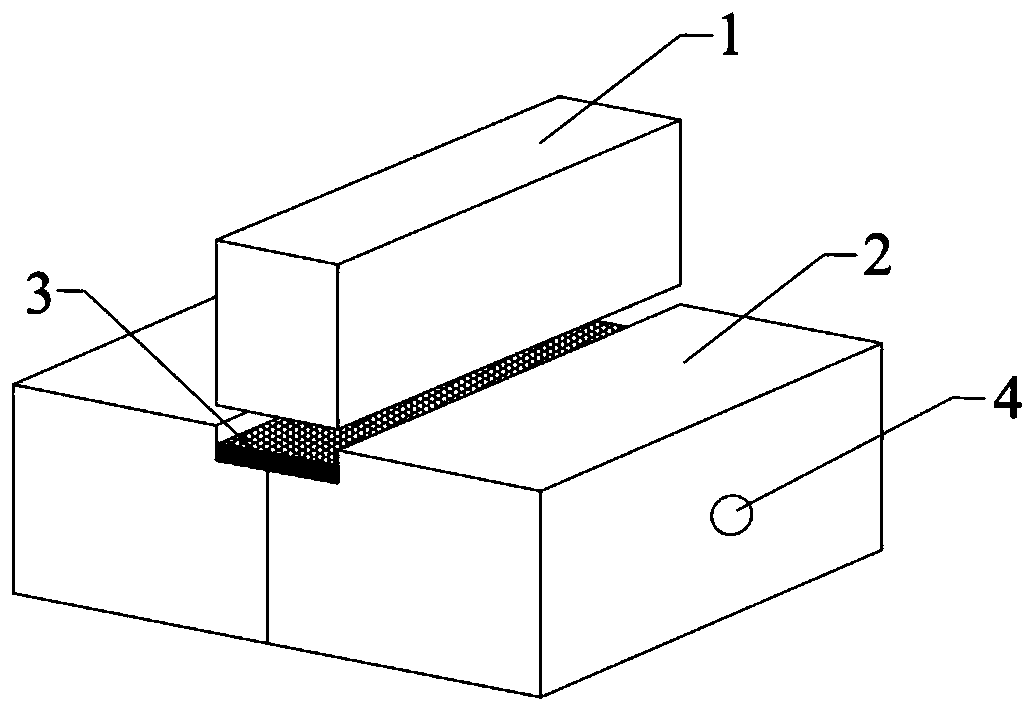

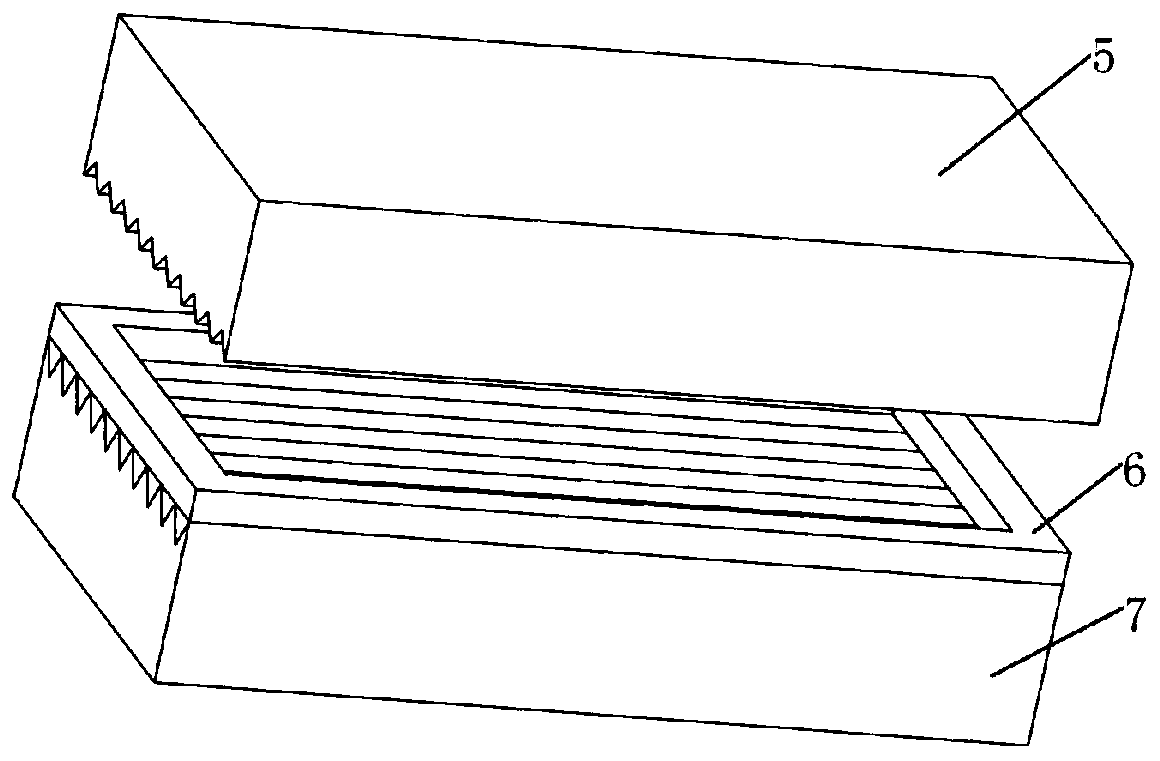

[0032] refer to figure 1 , figure 2 , image 3 , the laminated solid propellant molding die of this embodiment is composed of a die 1, a groove die 2, a fastening bolt 4, an upper curing plate 5, a height control frame plate 6, a lower curing plate 7 and an ammonium perchlorate sheet 3 ; Wherein, groove mold 2 cooperates with die 1 and is installed into convex shape structure, and groove mold 2 is the parts of two identical structures, and two groove mold 2 bodies have the threaded through hole that is positioned at coaxial line, two The groove mold 2 is connected by fastening bolts 4 and can be disassembled; the two groove molds 2 have grooves in the axial direction relative to the upper part, the groove mold 2 is placed horizontally on the test bench, and the pressure mold 1 is located above the groove mold 2 The width of die 1 is 1mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com