Foundation pit engineering high-pressure jet grouting pile reinforcement construction method

A technology of high-pressure rotary jetting pile and construction method, which is applied in basic structure engineering, excavation, directional drilling, etc., can solve the problems of low foundation pit construction safety hazards and large impact on the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

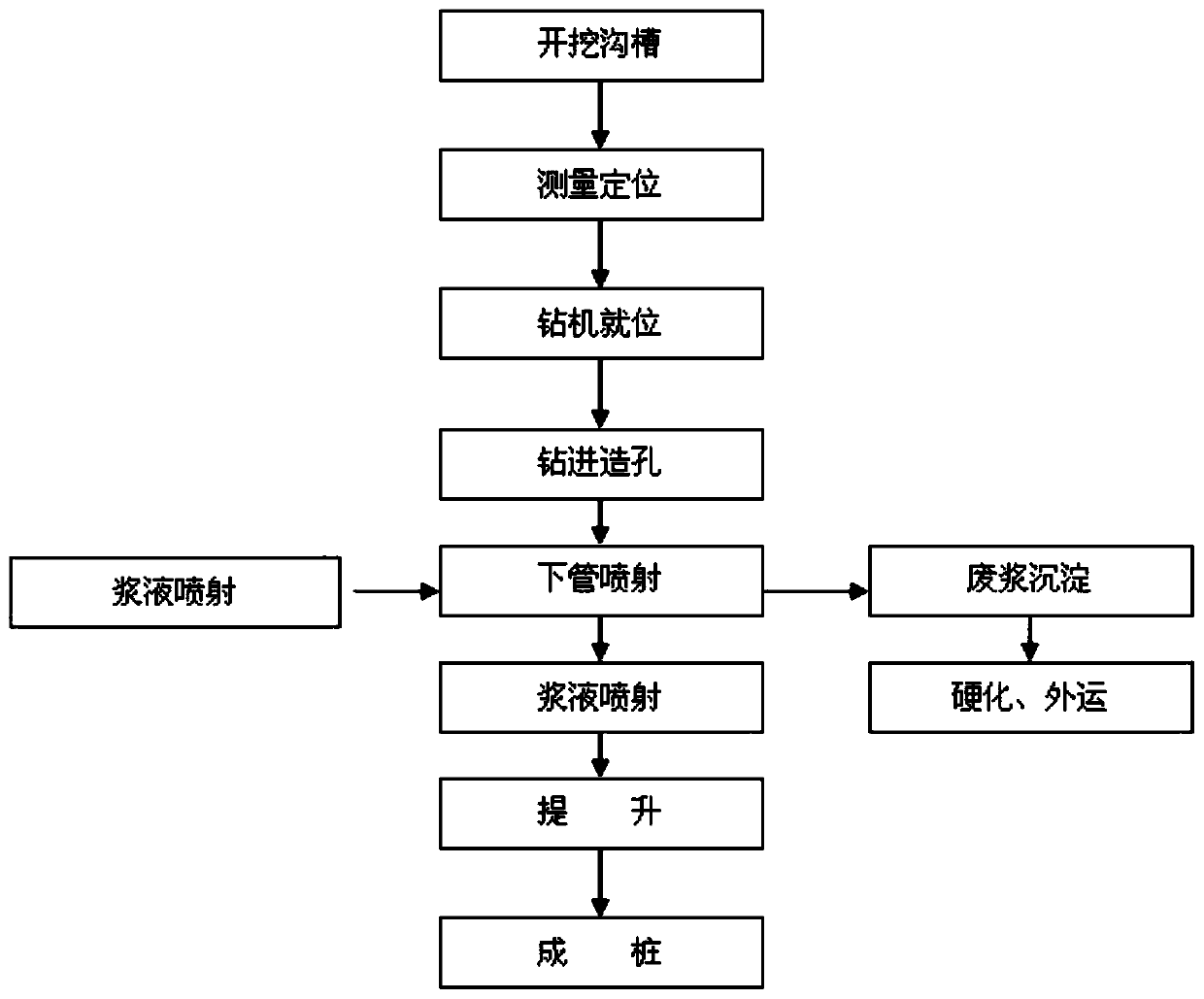

[0041] 1. The construction sequence of the present invention is as follows:

[0042] 1. Due to the intersection construction problem between the northwest and southeast corners of the reinforcement area and the B3 large opening support beam, the surrounding curtains of this part should be constructed first.

[0043] 2. Construction sequence from outside to inside: first construct the outermost row of rotary spray curtains, then construct the second row, and then construct the third row, forming a row-by-row centripetal construction sequence. This is beneficial to allow the cement slurry of each row of the inner ring except the outermost row to stay in the reinforcement area.

[0044] 3. The construction between the rows of piles of the present invention adopts the method of continuous construction hole by hole in sequence.

[0045] 2. Construction method

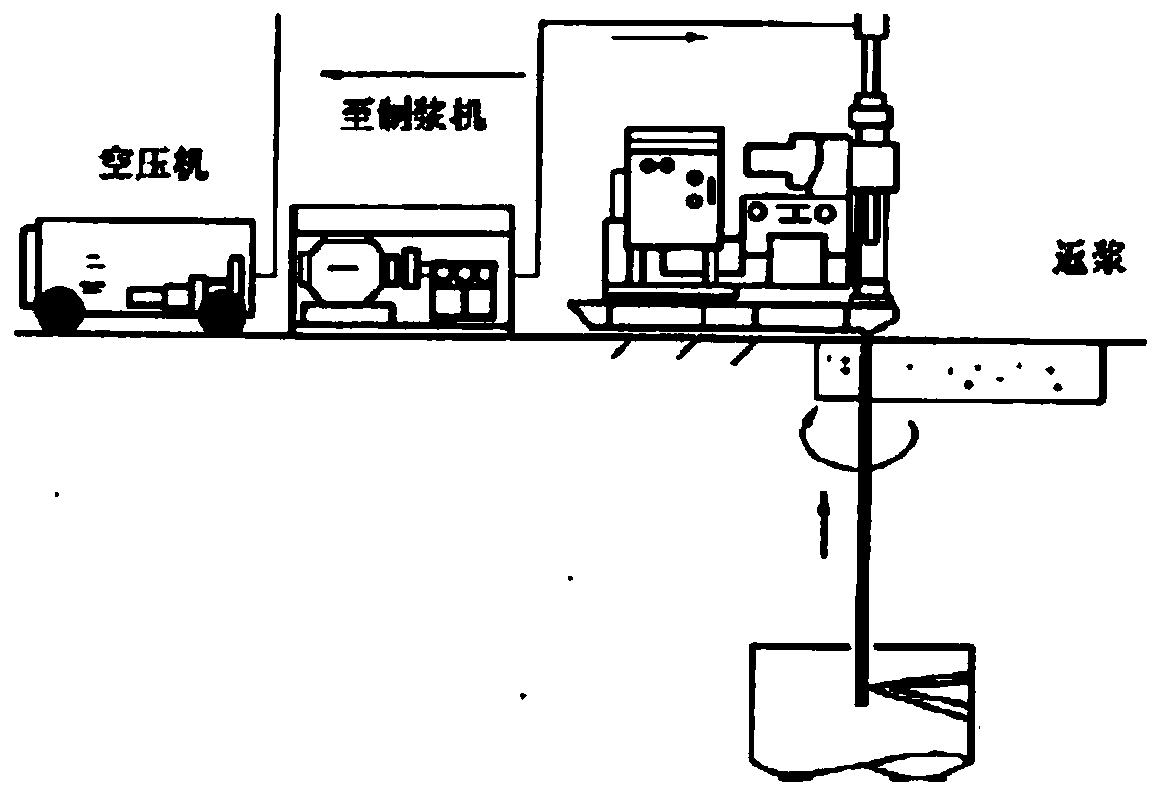

[0046] Such as figure 1 Schematic diagram of the double tube process principle and figure 2 Shown in the construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com