Assembling type novel adjustable dry hanging assembly

An adjustable and prefabricated technology, applied in covering/lining, construction, building construction, etc., can solve problems such as labor-intensive and difficult installation, achieve simple and convenient operation, reduce welders, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

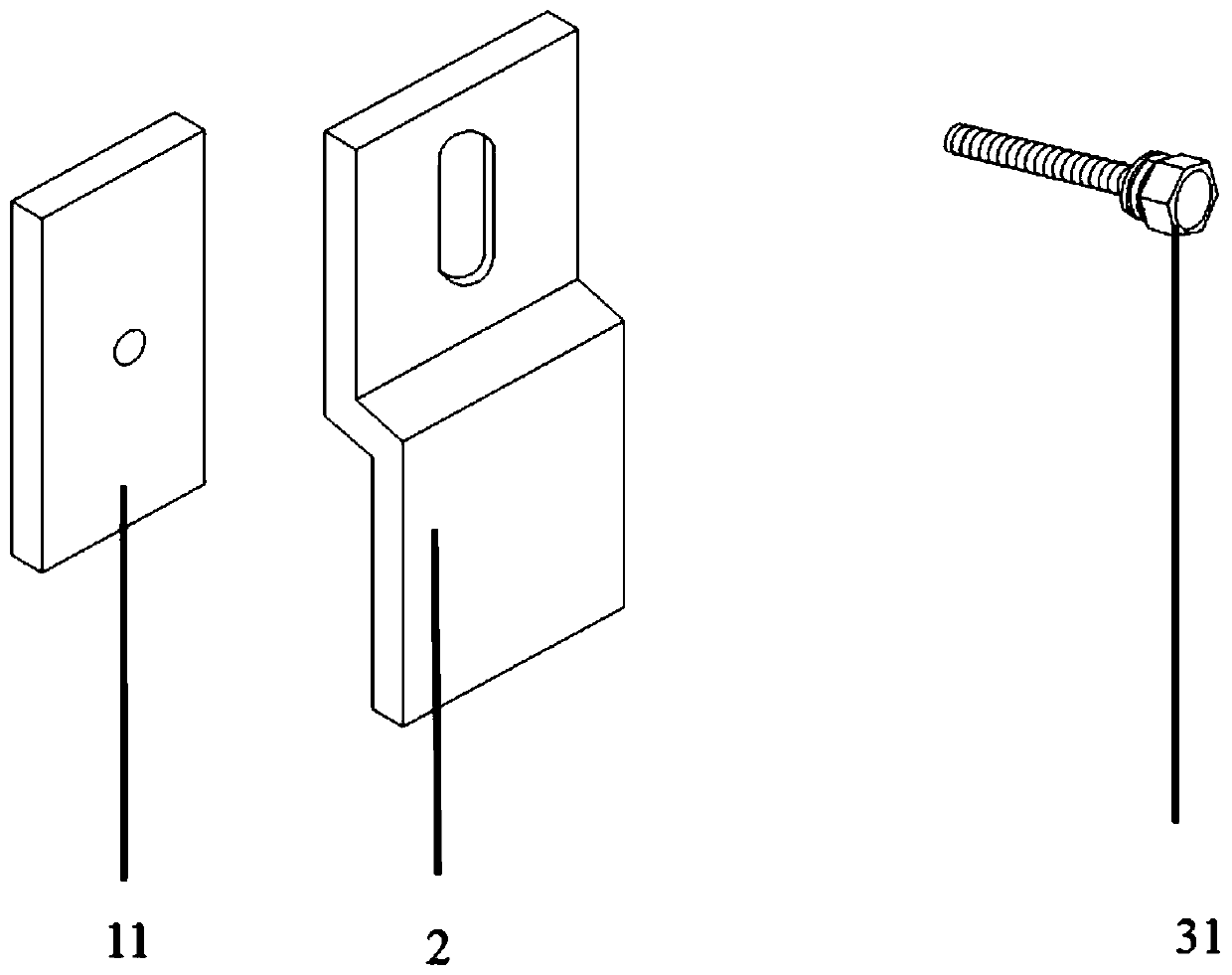

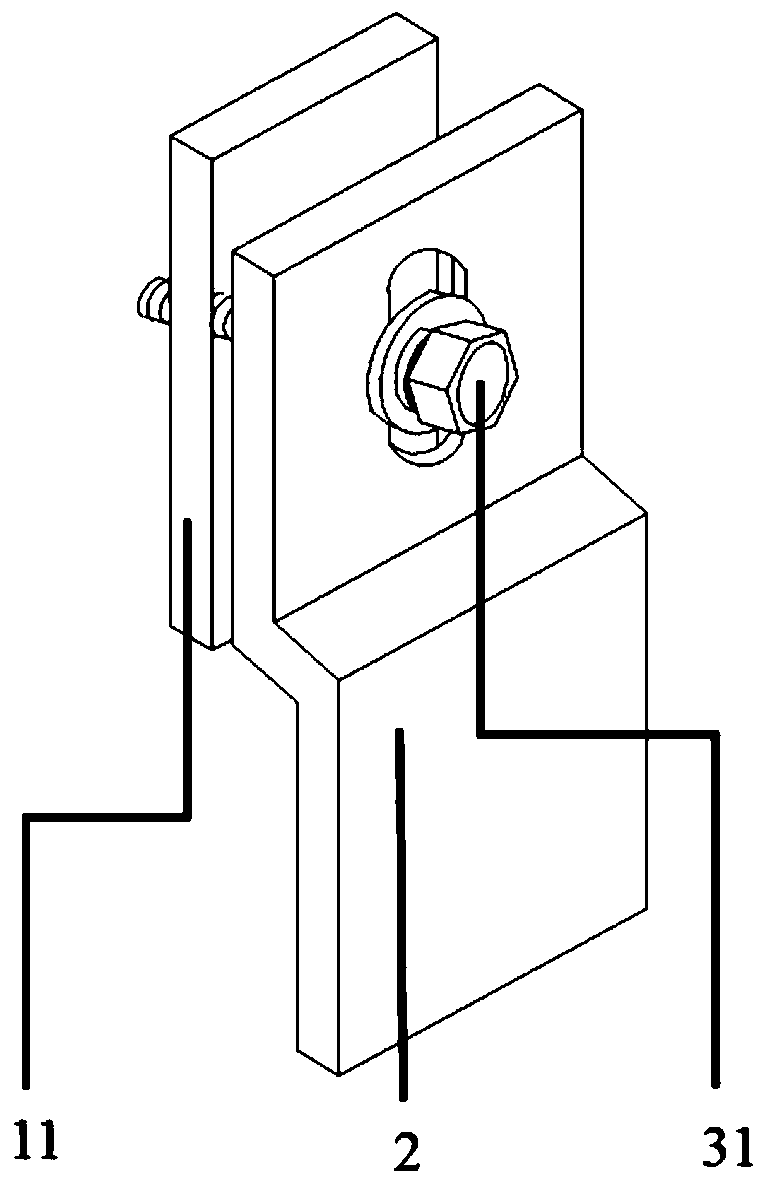

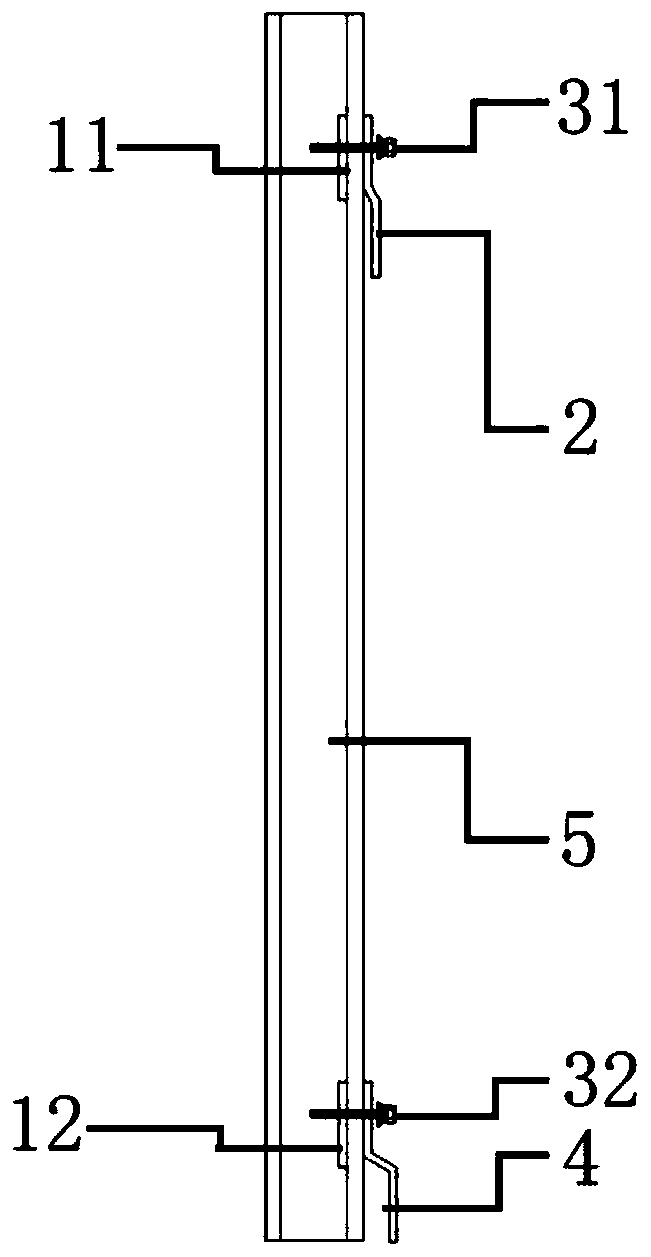

[0036] see Figures 1 to 9 As shown, Embodiment 1 of the present invention discloses a new type of assembled adjustable dry hanging assembly, including: a column 8, a first buckle slide rail 61 fixed on the column 8 and a hook located below the first buckle slide rail 61. The second buckle slide rail 62 and the first buckle assembly on the first buckle slide rail 61 and the second buckle assembly on the second buckle slide rail 62, the first buckle Slide rail 61 is arranged in parallel with second buckle slide rail 62; Wherein, described column 8 selects galvanized square pass for use, and described first buckle slide rail 61 and second buckle slide rail 62 select galvanized angle steel for use;

[0037] The first buckle assembly includes a first screw seat part 11 embedded in the surface plate 5 and a first metal connecting part 2 fixed to the first screw seat part 11 via a first bolt 31. The first metal The connecting piece 2 and the first buckle slide rail 61 cooperate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com