Rotating shaft for automatic gear shifter

A technology for automatic shifting and rotating shafts, applied to components with teeth, transmission control, belts/chains/gears, etc., can solve problems such as troublesome assembly and complex structure, and achieve simple assembly, simple structure, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and specific embodiments.

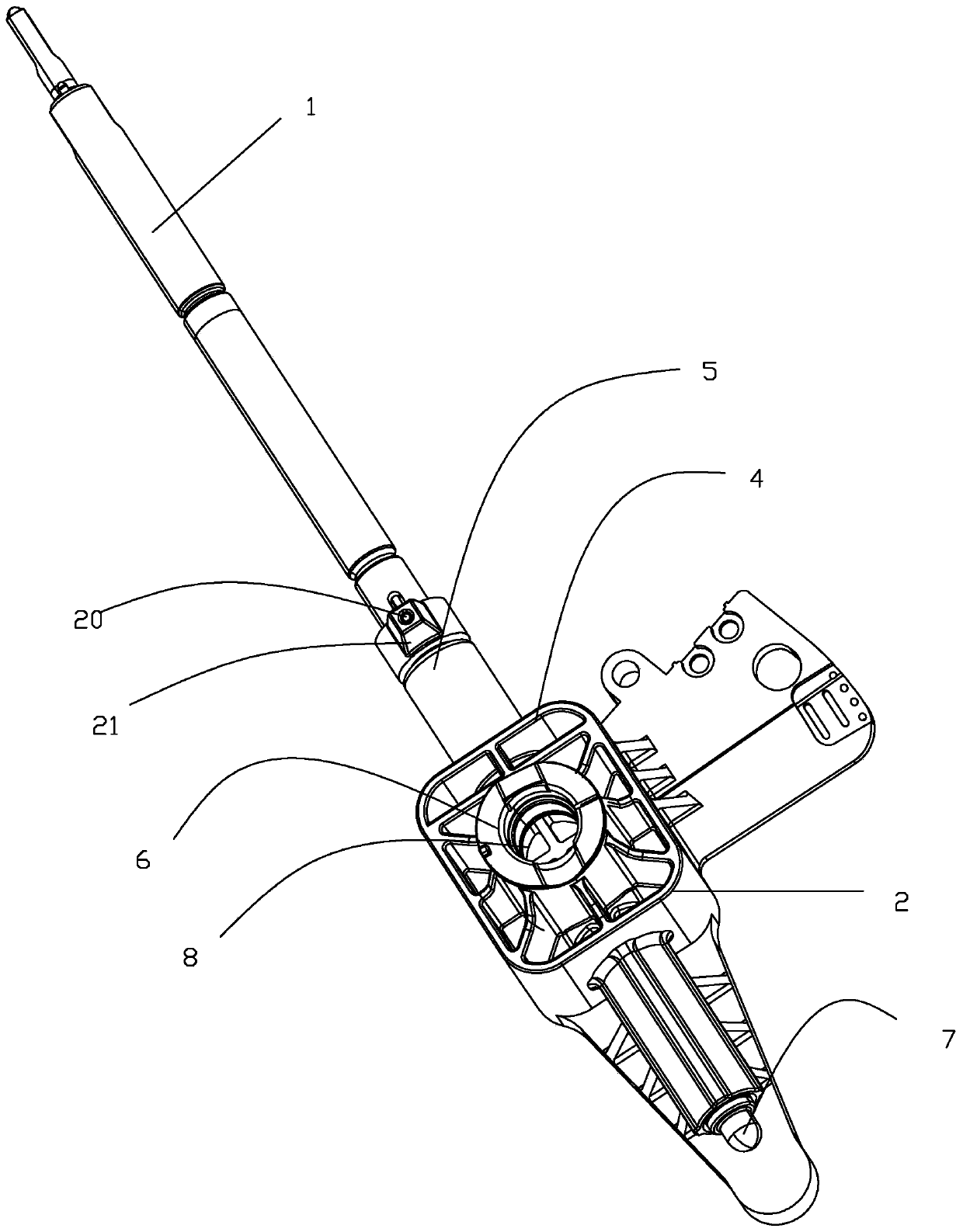

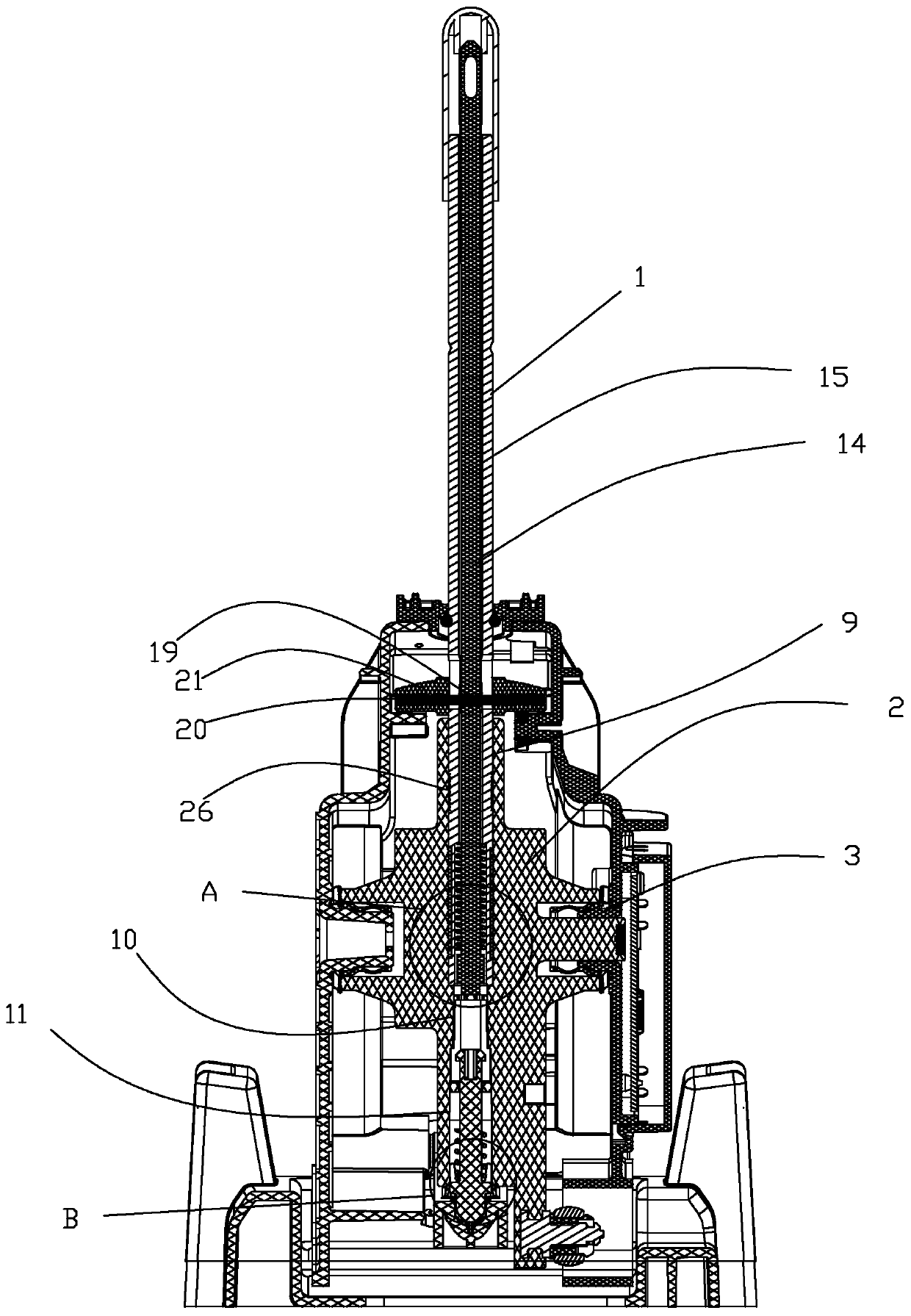

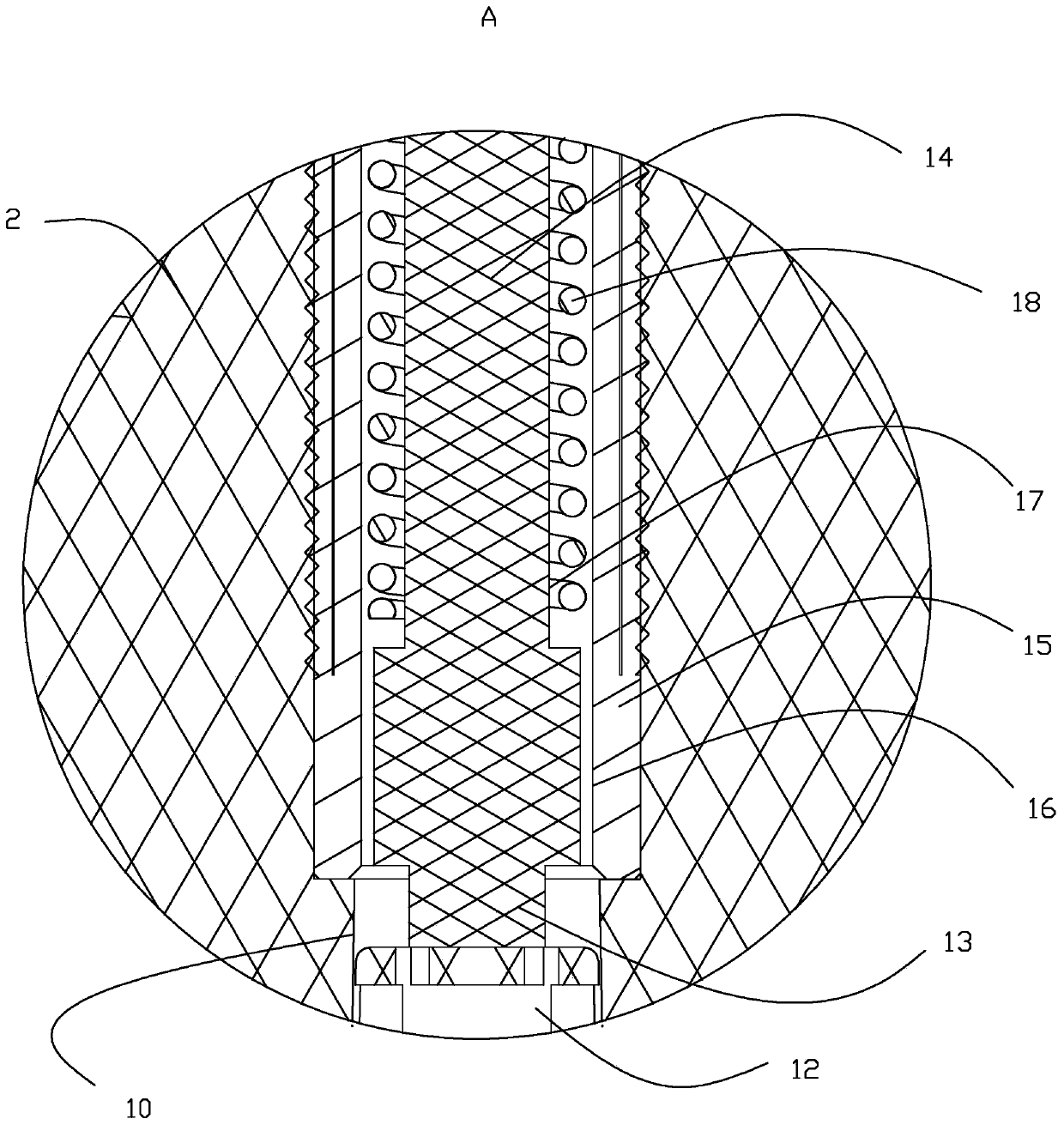

[0021] As shown in the figure, the present invention provides a rotating shaft for an automatic shifter, which includes a handle 1, a rotating shaft 2 and a toggle lever 7 arranged in the automatic shifter, and also includes a shaft sleeve 12 and an automatic gear shifter. The ring seat 3 on the left and right sides of the shifter, the rotating shaft 2 includes a square seat 4 and a vertical pipe 5. The front and rear sides of the square seat 4 are provided with protrusions 6 protruding from the side of the square seat 6. A groove 8 is provided on the protrusion 6, and the ring seat 4 is rotationally matched with the groove 8, the vertical pipe 5 is arranged in the square seat 4, and the vertical pipe 5 extends from the upper and lower sides of the square seat 4, respectively. At both ends, the vertical pipe 5 is provided with a channel along the axis of the v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap