Adjustable revolution speed sensor support

A technology of speed sensor and sensor bracket, which is applied in the field of machinery, can solve the problems of inaccurate positioning, poor installation process, large amount of welding thermal deformation, etc., and achieve the effect of simple processing process and avoiding large amount of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described with reference to the drawings and specific embodiments.

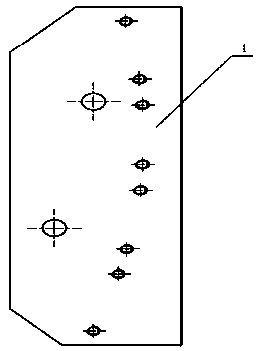

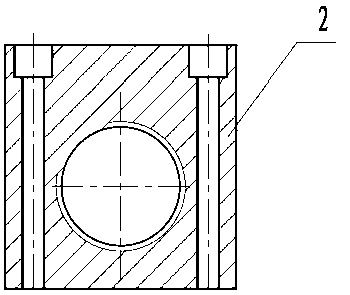

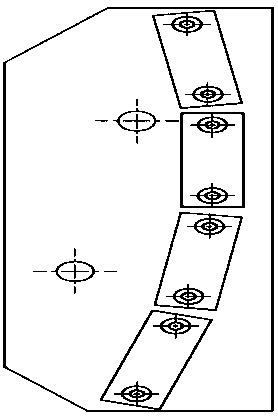

[0015] An adjustable speed sensor bracket, the adjustable speed sensor bracket has a fixed bottom plate for fixing on the front end cover of the diesel engine; figure 1 As shown, the fixed base plate 1 is a flat plate structure; both ends of the end face of one side in the width direction of the fixed base plate 1 have a missing corner indicating the installation direction; the fixed base plate 1 is fixed with a sensor bracket 2; The sensor support 2 is a plurality of being fixed on the fixed base plate 1, and a plurality of described sensor supports form arc-shaped installation arrangement on the described fixed base plate; Described sensor support is such as figure 2 As shown, it is a plate processing part. The sensor bracket is designed with a circular light hole, and its size is slightly larger than the specification of the mounting threaded hole of the connecting piece. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com