Fault diagnosis method of aero-engine exhaust temperature sensors

A technology for exhaust temperature and fault diagnosis, applied in instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as increased probability of misjudgment and high failure rate, and achieve the effect of accurate temperature data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

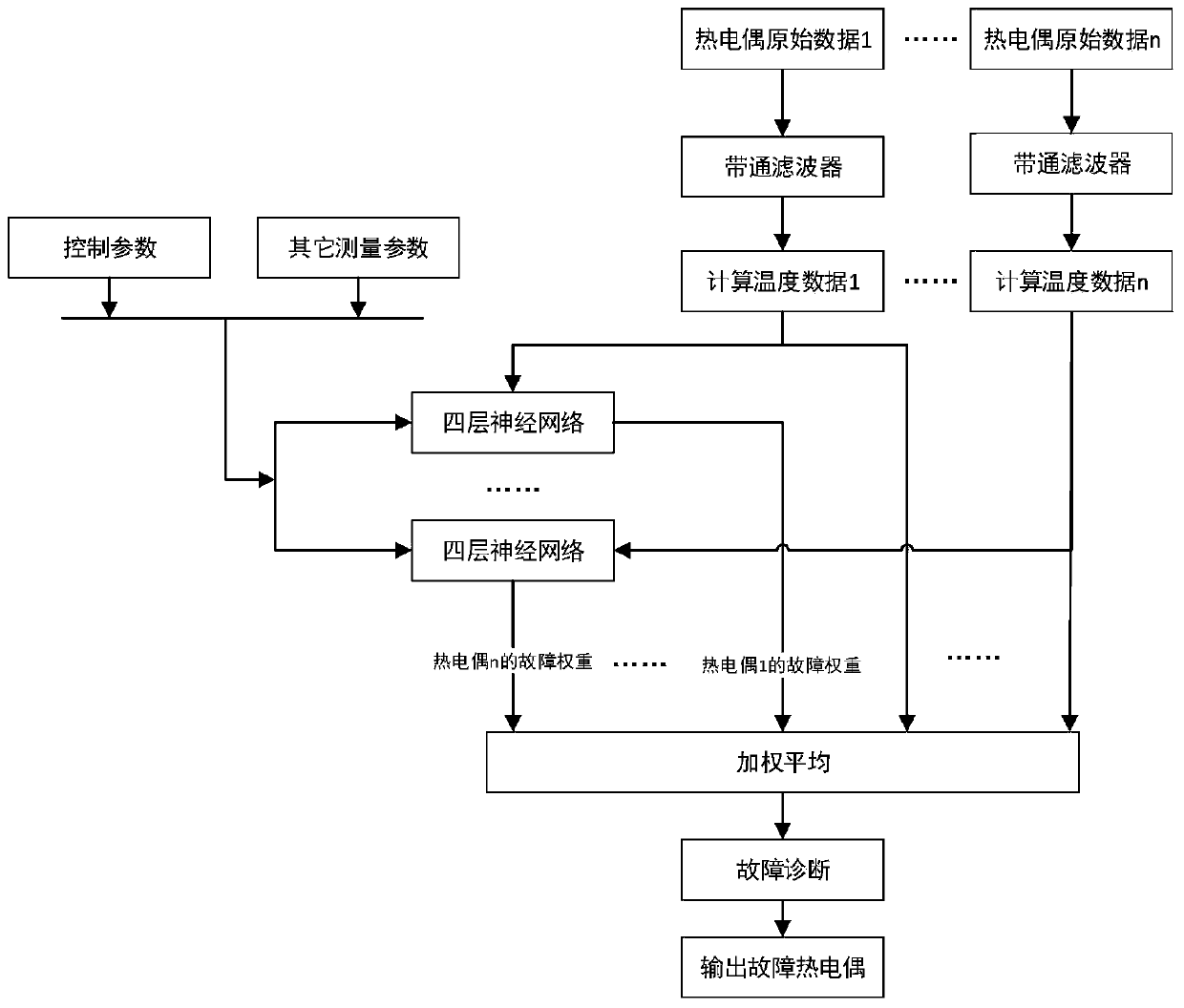

Method used

Image

Examples

Embodiment 1

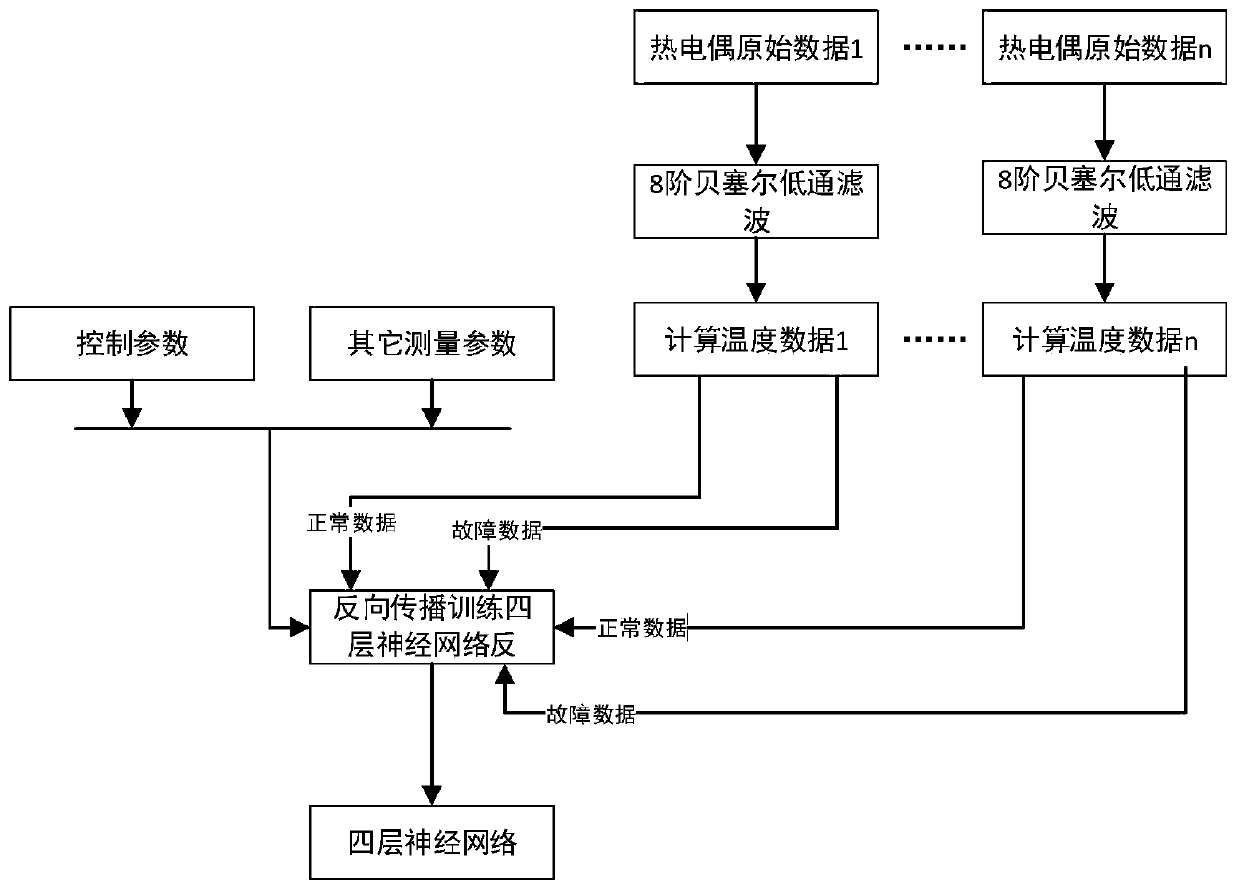

[0050] Such as figure 2 As shown, it is the training stage of the four-layer neural network in the present invention, which requires a large amount of data indicating whether the thermocouple is faulty. In the engine design stage, a large amount of data will be generated. According to the type of thermocouple failure, different types of fault thermocouple measurement data are added to obtain correct data and fault data, and two types of data are manually identified. A four-layer neural network can be trained on this data. The training process is to use the neural network backpropagation algorithm to modify the parameters step by step, specifically using the gradient descent algorithm.

[0051] This embodiment provides a fault diagnosis method for an aero-engine exhaust temperature sensor, comprising the following steps:

[0052] A1. Four thermocouple sensors are evenly arranged on the same section between the high-pressure turbine and the low-pressure turbine of the engine....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com