Wind driven generator liquid cooling device and wind driven generator comprising same

A technology for wind turbines and generators, applied in the field of wind turbines and wind turbine liquid cooling devices, can solve problems such as corrosion of motor structural parts, reduction of the life of key components such as insulation, and easy leakage of liquid cooling, so as to reduce the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

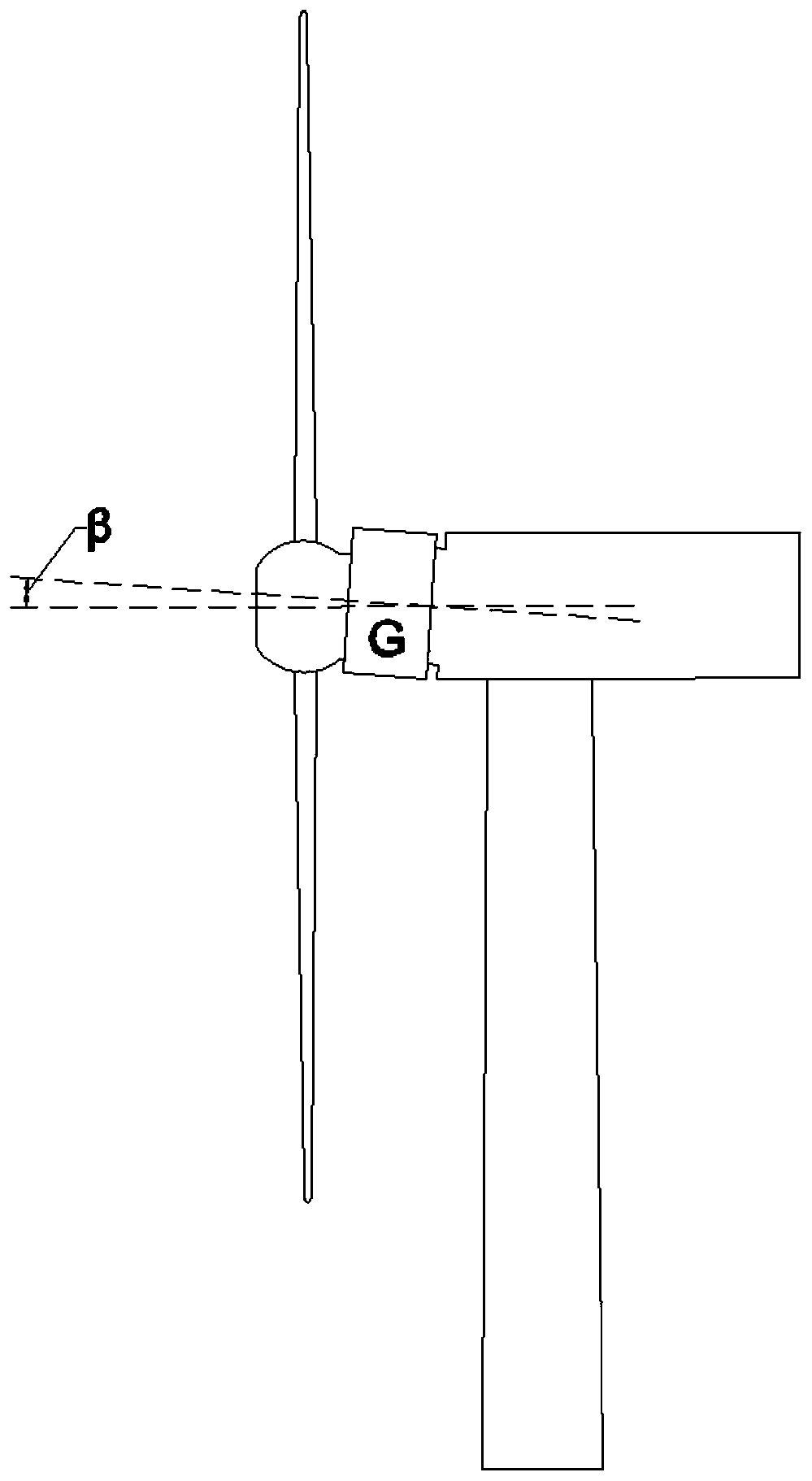

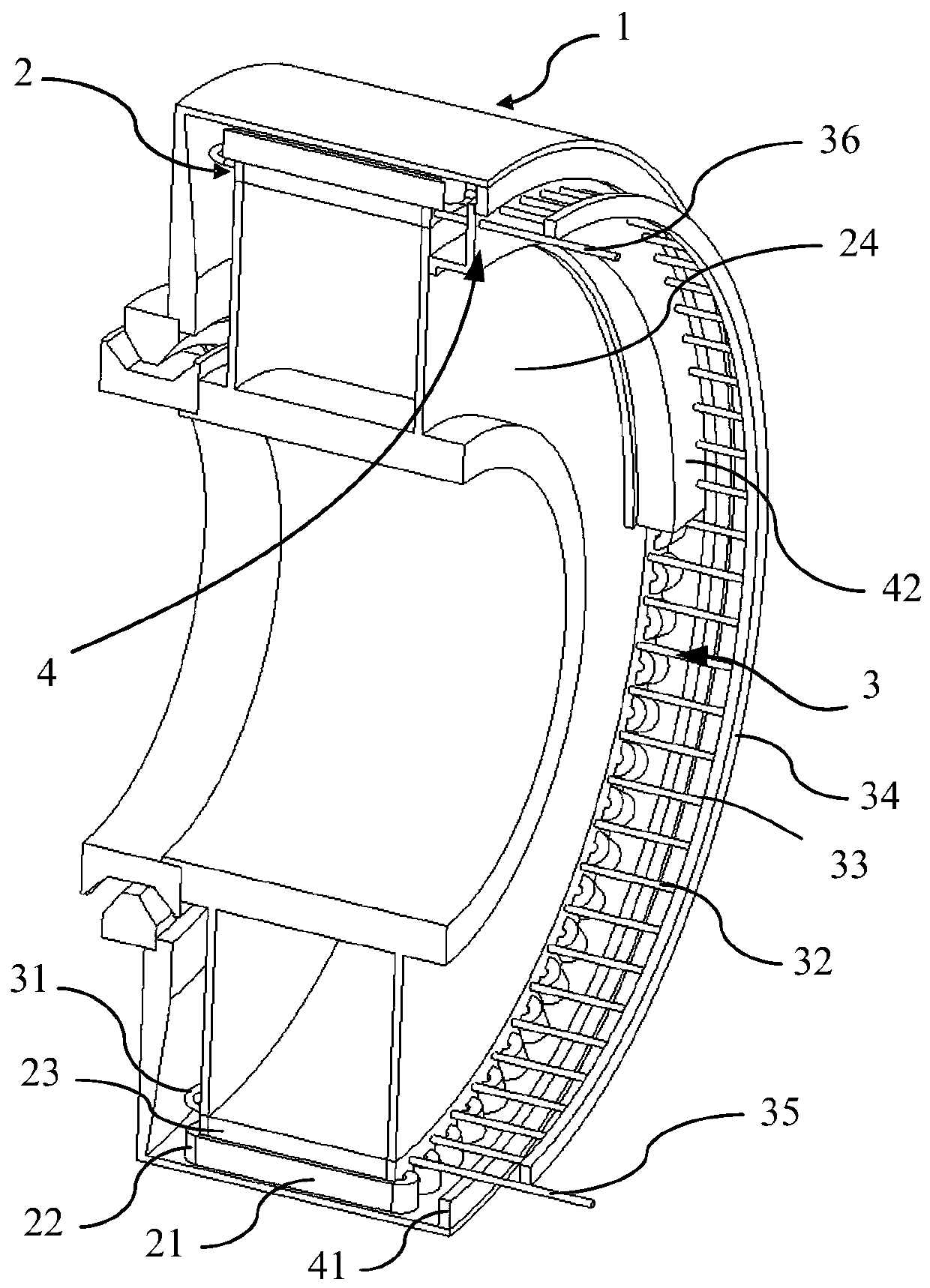

[0034] Such as Figure 1-Figure 4 As shown, this embodiment discloses a wind power generator, which includes a liquid cooling device for the wind power generator. The wind power generator liquid cooling device of this embodiment includes a generator G and a liquid cooling pipe 3 . Wherein, the generator G includes a driving end and a non-driving end, and the generator G is inclined relative to the horizontal plane so that the driving end is higher than the non-driving end. Among them, such as figure 1 As shown, the generator G forms an angle β with the horizontal plane. The size of the included angle β can be determined according to actual application conditions.

[0035] Such as figure 2 , image 3 and Figure 4 As shown, the liquid cooling device of the wind power generator in this embodiment also includes a liquid cooling pipe 3 for cooling liquid, the liquid cooling pipe 3 is arranged in the generator G, and the connection 33 of the liquid cooling pipe 3 is arranged...

Embodiment 2

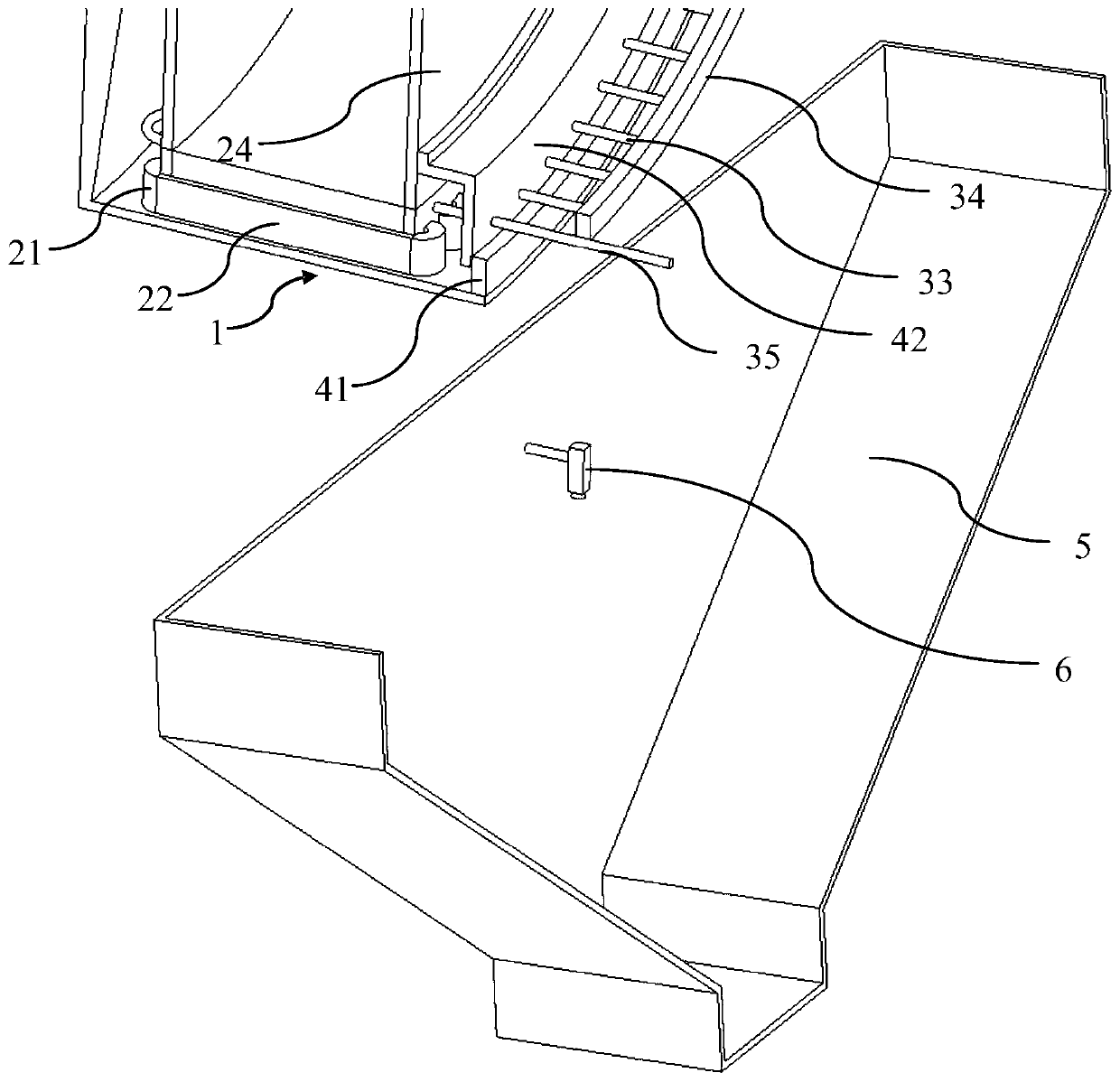

[0050] Such as Figure 5 and Figure 6 As shown, this embodiment discloses another liquid cooling device for wind power generators. Wherein, the generator of this embodiment further includes a stator 2 and a rotor 1 , and the sealing assembly 4 further includes a moving end 41 and a stationary end 42 . Wherein, the moving end 41 is connected to the rotor 1 , and the stationary end 42 is connected to the stator 2 , and the moving end 41 and the stationary end 42 cooperate with each other to form a seal. The sealing assembly 4 is divided into a stationary end 42 and a moving end 41 respectively connected to the stator 2 and the rotor 1 , so that the sealing assembly 4 does not interfere with the relative movement between the stator 2 and the rotor 1 while completing the sealing.

[0051] Such as Figure 5 and Figure 6 As shown, the moving end 41 in this embodiment extends around the circumference of the rotor 1, and the stationary end 42 extends around the circumference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com