Small green-vegetable harvester with vacuum suction device

A technology of vacuum adsorption and vacuum adsorption holes, applied in the direction of harvesters, conveyors, cutters, etc., can solve the problems of falling small vegetables, easy sliding, high cost, etc., to save space, enhance friction, and increase friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

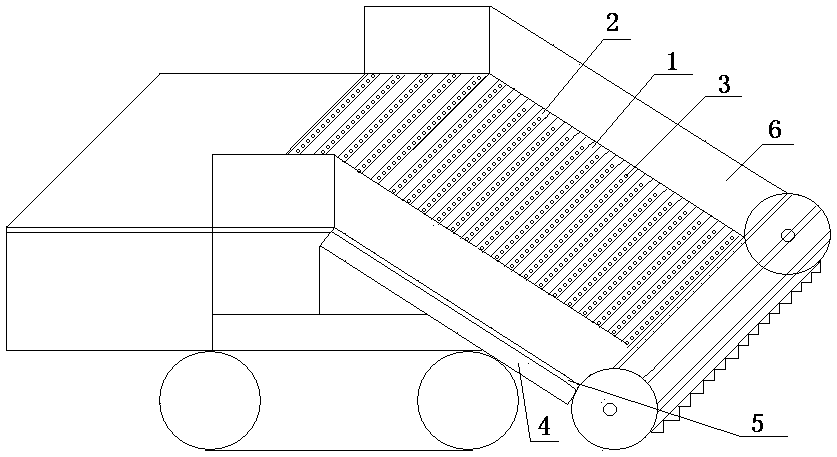

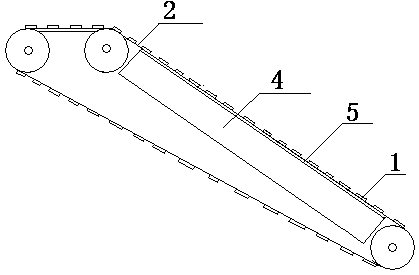

[0026] like figure 1 and figure 2 As shown, the small vegetable harvester equipped with a vacuum adsorption device includes a harvesting device, a conveyor belt, a collection device, a motor, and wheels. One end of the conveyor belt is connected to the harvesting device, and the other end is connected to the collection device. 1 and a group of groove layers 2, two adjacent protrusion layers 1 and groove layers 2 are alternately connected, the shape of the protrusion layer 1 is rectangular, triangular or elliptical, and the protrusion layer 1 and the groove layer 2 are connected alternately. The groove layers 2 are alternately connected along the conveying direction of the conveyor belt. The raised layer 1 is provided with anti-slip textures, the groove layer 2 is provided with a group of adsorption holes 3, and a vacuum adsorption device 4 is provided below the upper conveyor belt. A vacuum generator is provided, and an adsorption plate 5 with a smooth surface is passed betw...

Embodiment 2

[0034] like figure 1 and figure 2 As shown, the small vegetable harvester equipped with a vacuum adsorption device includes a harvesting device, a conveyor belt, a collection device, a motor, and wheels. One end of the conveyor belt is connected to the harvesting device, and the other end is connected to the collection device. 1 and a group of groove layers 2, two adjacent protrusion layers 1 and groove layers 2 are alternately connected, the shape of the protrusion layer 1 is rectangular, triangular or elliptical, and the protrusion layer 1 and the groove layer 2 are connected alternately. The groove layers 2 are alternately connected along the conveying direction of the conveyor belt. The raised layer 1 is provided with anti-slip textures, the groove layer 2 is provided with a group of adsorption holes 3, and a vacuum adsorption device 4 is provided below the upper conveyor belt. A vacuum generator is provided, and an adsorption plate 5 with a smooth surface is passed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com