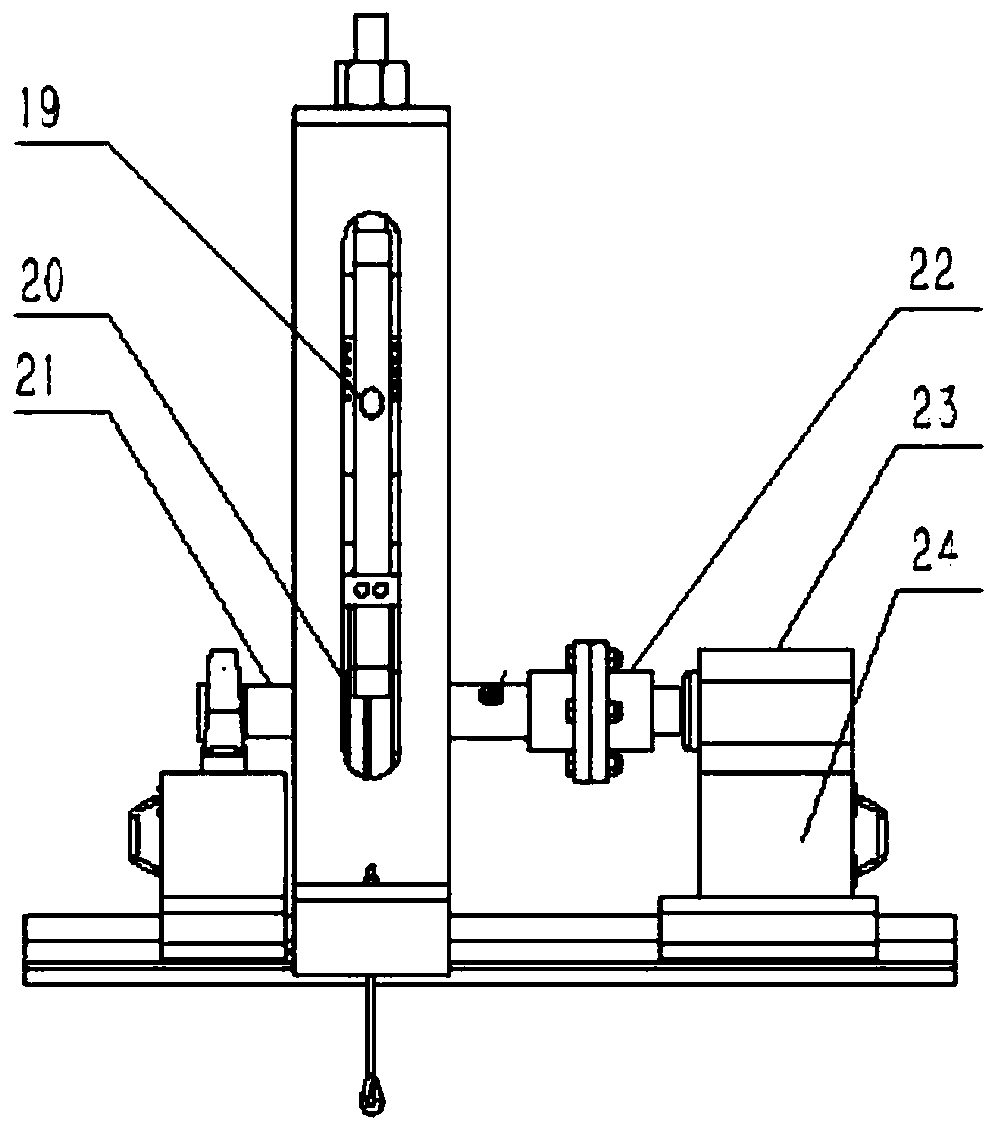

A device for repairing wheel treads using additive materials

一种修复车轮、踏面的技术,应用在增材加工、车辆部件、运输和包装等方向,能够解决车轮尺寸小、浪费人力物力财力等问题,达到节约材料、避免车轮尺寸变小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0022] The purpose of the present invention is to provide a device for repairing wheel treads by using additive materials to solve the problems existing in the prior art. It can avoid repairing the wheel and causing the wheel to become smaller in size and be scrapped, which is conducive to saving materials, and the repair process is carried out automatically, saving Save time and effort.

[0023] In order to make the above objects, features and advantages of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com