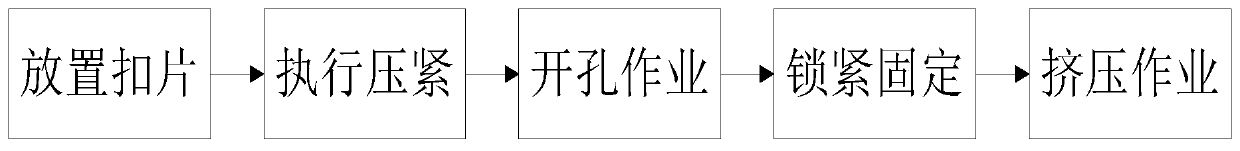

Switch socket buckling piece shaping device and shaping method

A technology of shaping device and buckle, applied in transportation and packaging, other manufacturing equipment/tools, molding tools, etc., can solve the problems of long time consumption, complex process, low production efficiency, etc., to save time and reduce process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

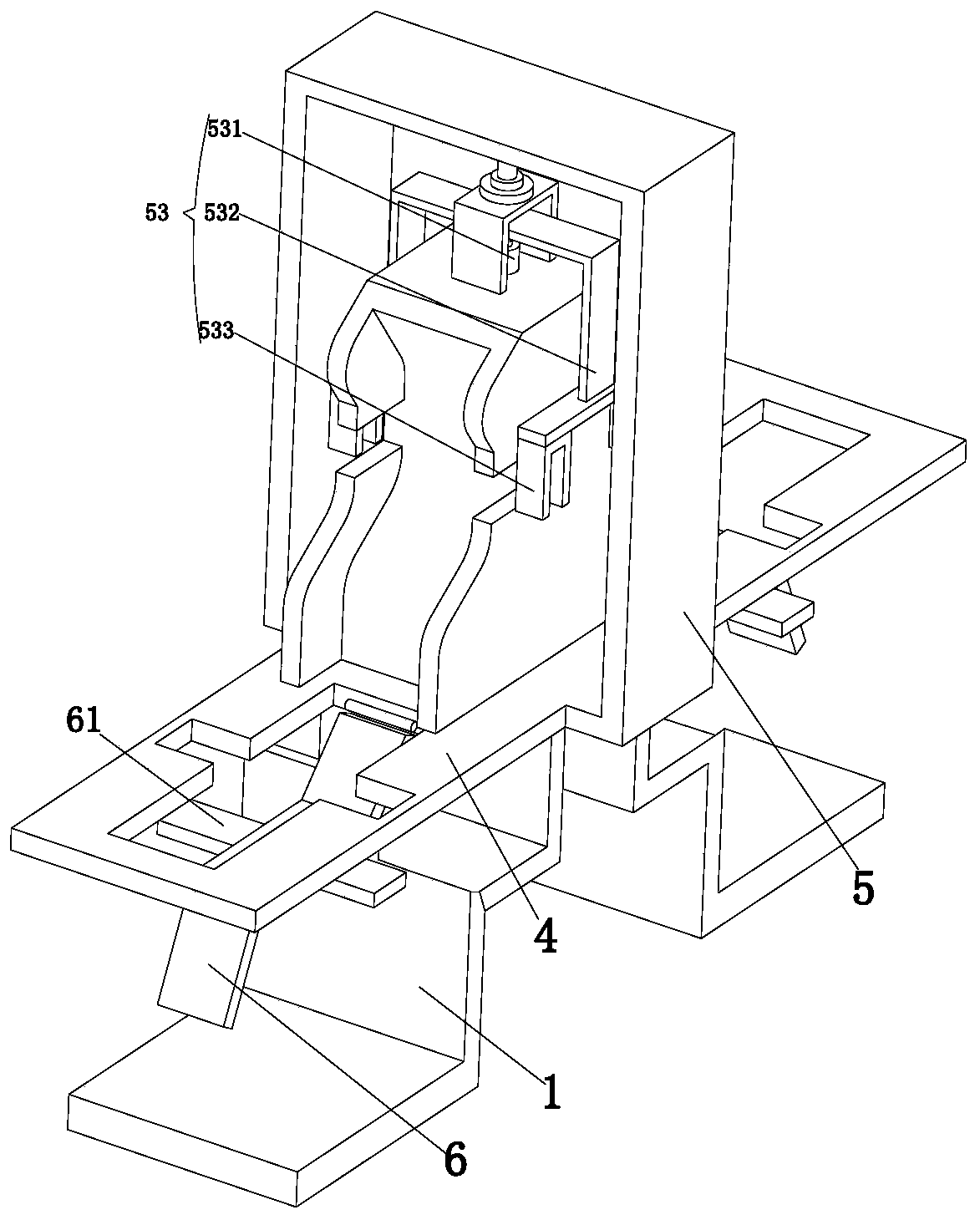

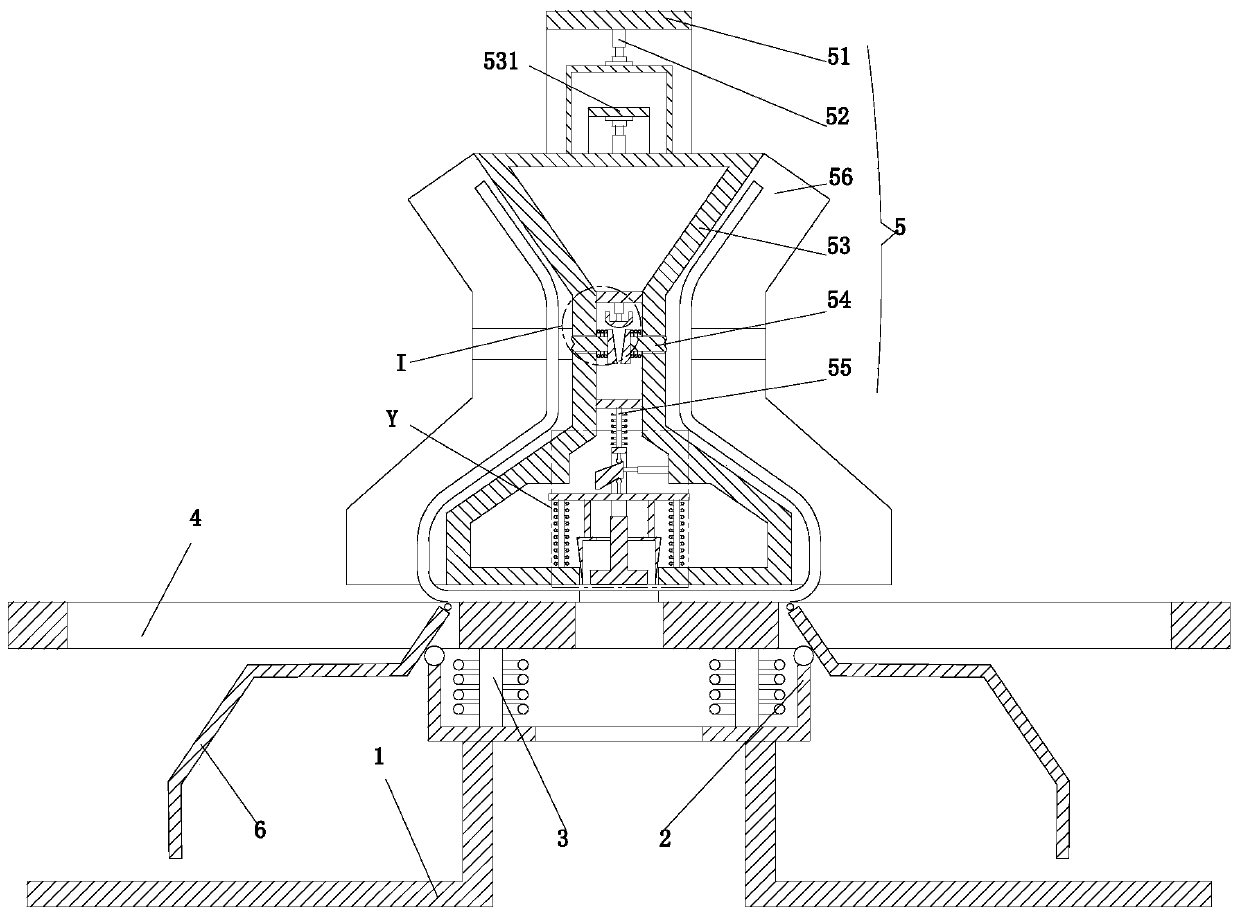

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0036] Such as Figure 1 to Figure 6 As shown, a switch socket buckle shaping device includes a support base 1, and a support plate 2 is symmetrically arranged on the support base 1, and a shaping base 4 is installed on the support base 1 through a telescopic plate 3, and the shaping base 4 is Plastic mold 5 is installed;

[0037] The shaping bottom plate 4 is symmetrically provided with a shaping groove, and a shaping frame 6 is arranged through a pin shaft in the shaping groove, and the shaping frame 6 is leaned against the abutment plate 2

[0038] The shaping mold 5 includes a fixing bracket 51 installed on the shaping base plate 4, a shaping cylinder 52 is installed on the lower end of the fixing bracket 51, a shaping frame 53 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com