Patents

Literature

47results about How to "Efficient and convenient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

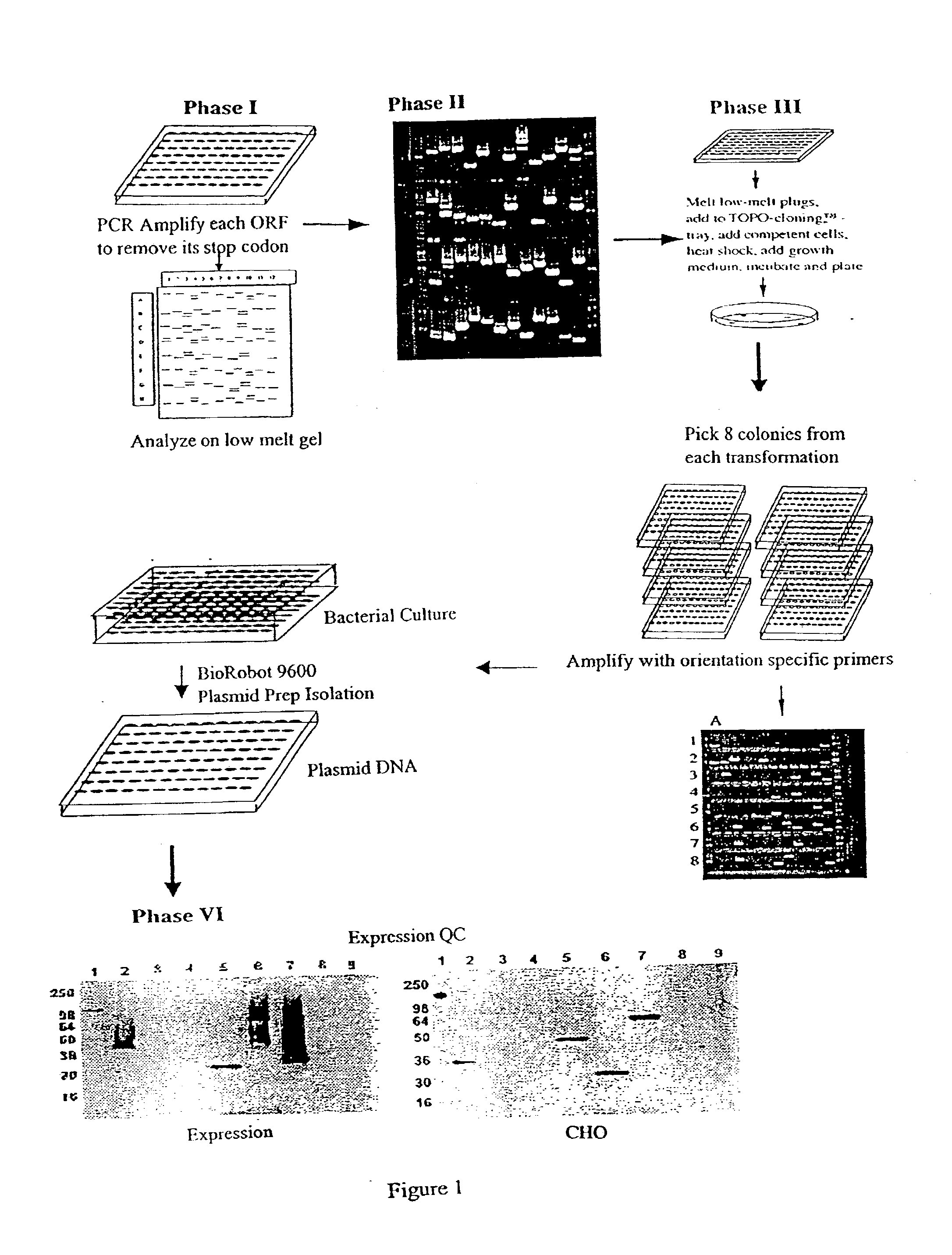

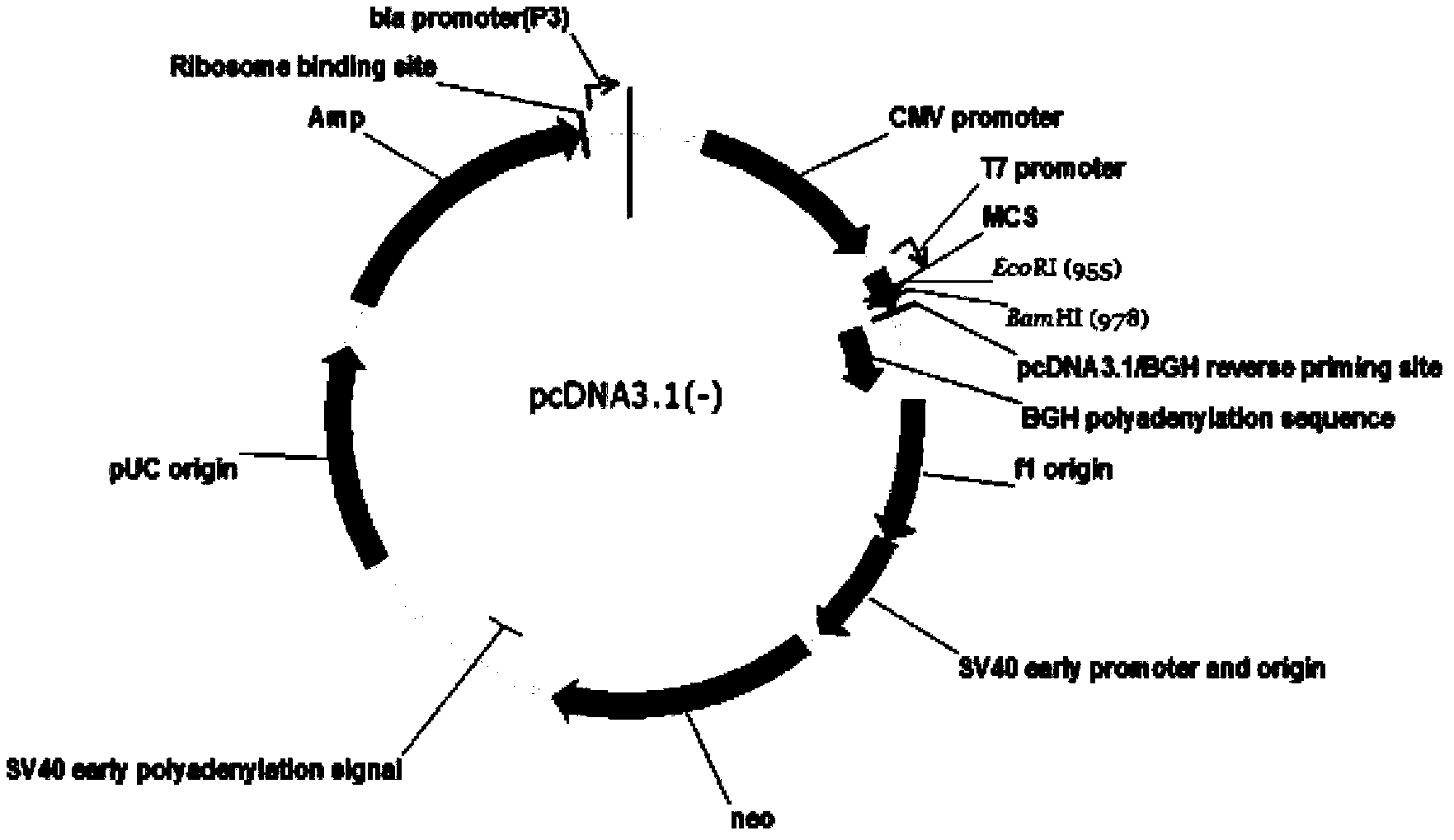

Methods for producing libraries of expressible gene sequences

InactiveUS20040009477A1Efficient and convenient productionLow costMicrobiological testing/measurementBiological testingGeneComputational biology

The present invention comprises a method for producing libraries of expressible gene sequences. The method of the invention allows for the simultaneous manipulation of multiple gene sequences and thus allows libraries to be created in an efficient and high throughput manner. The expression vectors containing verified gene sequences can be used to transfect cells for the production of recombinant proteins. The invention further comprises libraries of expressible gene sequences produced using the method of the invention and expression vectors used in the construction of said libraries.

Owner:LIFE TECH CORP

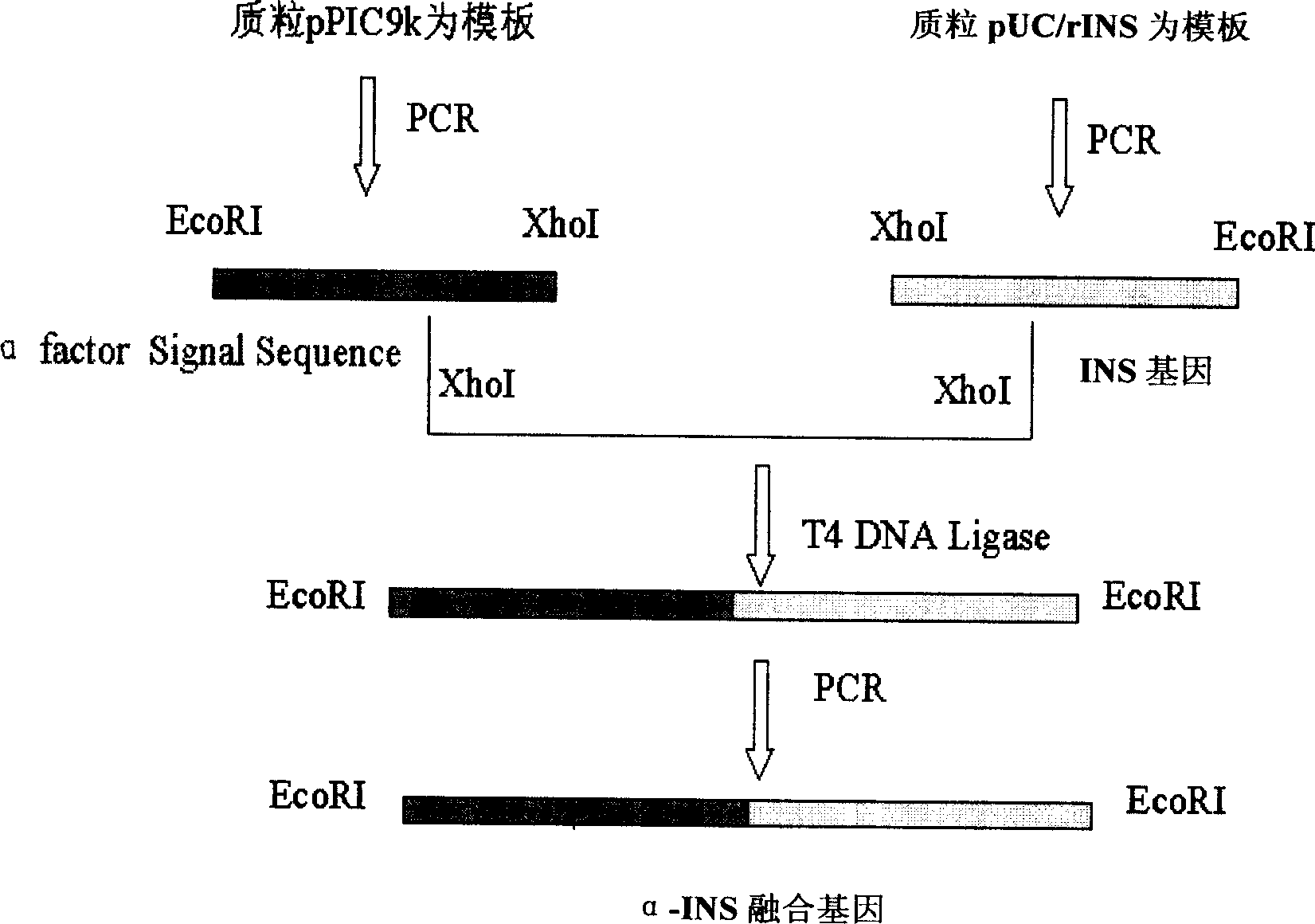

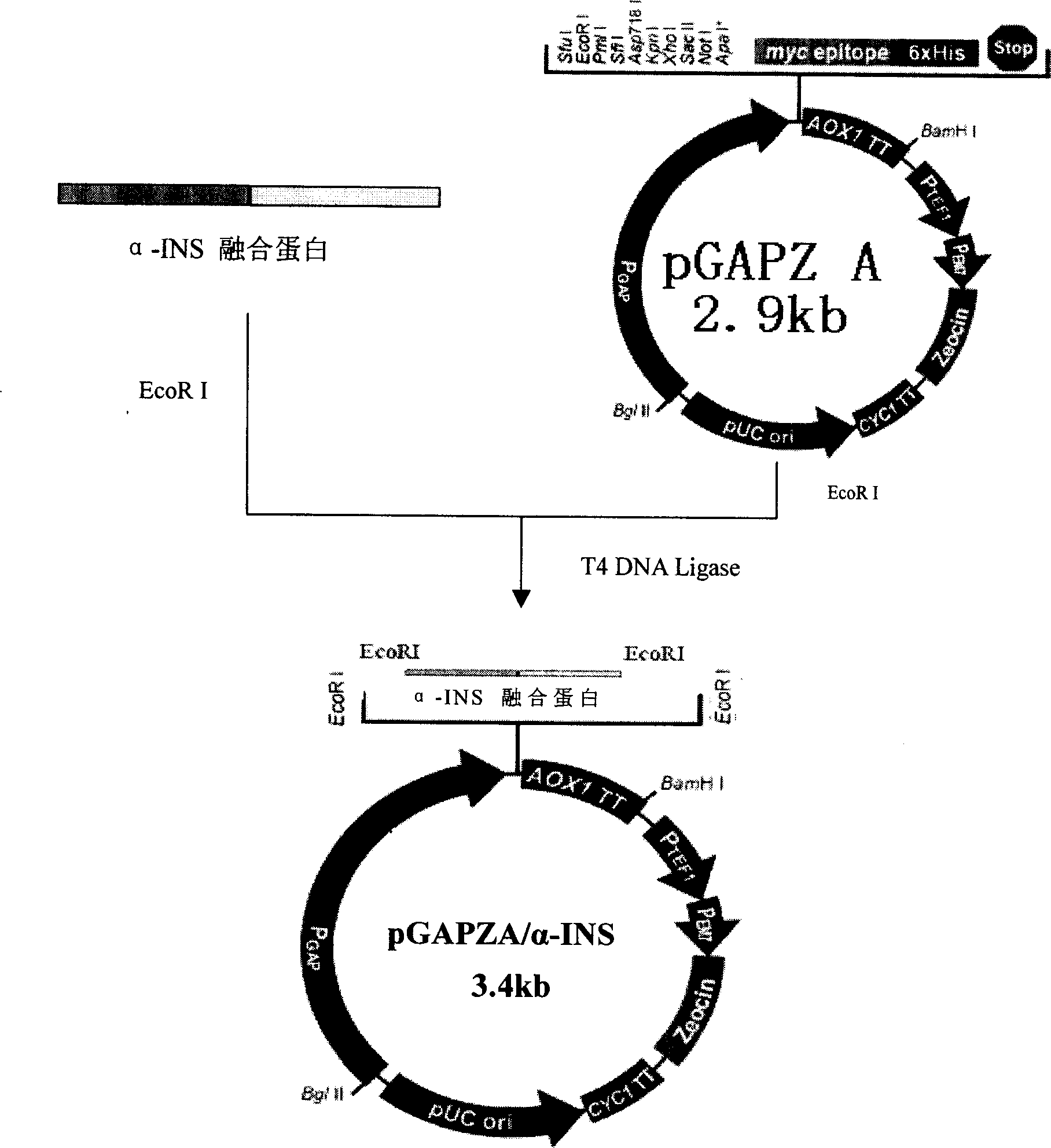

Method for producing recombined human proinsulin

This invention provides a method for producing recombinant human proinsulin from N-end leader peptide, and relevant expression vector. The method comprises: (1) fusing yeast alpha-factor leader peptide sequence and the human proinsulin N-end leader peptide, and introducing into a yeast constitutive expression vector; (2) transferring into Pichia pastoris cells to realize constitutive and secretory expression; (3) fermenting and purifying. The recombinant human proinsulin has such advantages as high stability, high activity and simple production. The method has such advantages as high expression level, high purification yield, and high efficiency.

Owner:SHANGHAI NEWSUMMIT BIOPHARMA

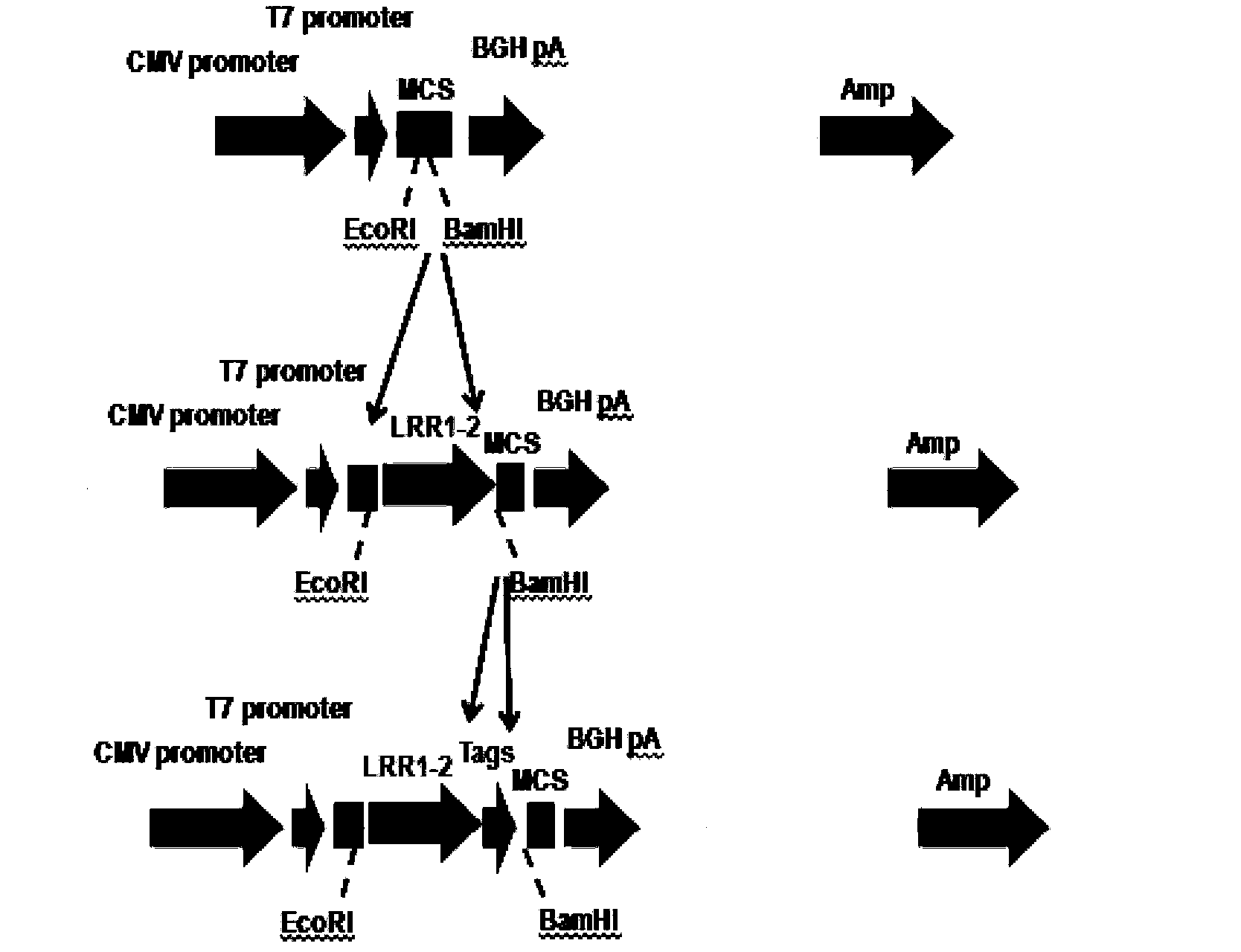

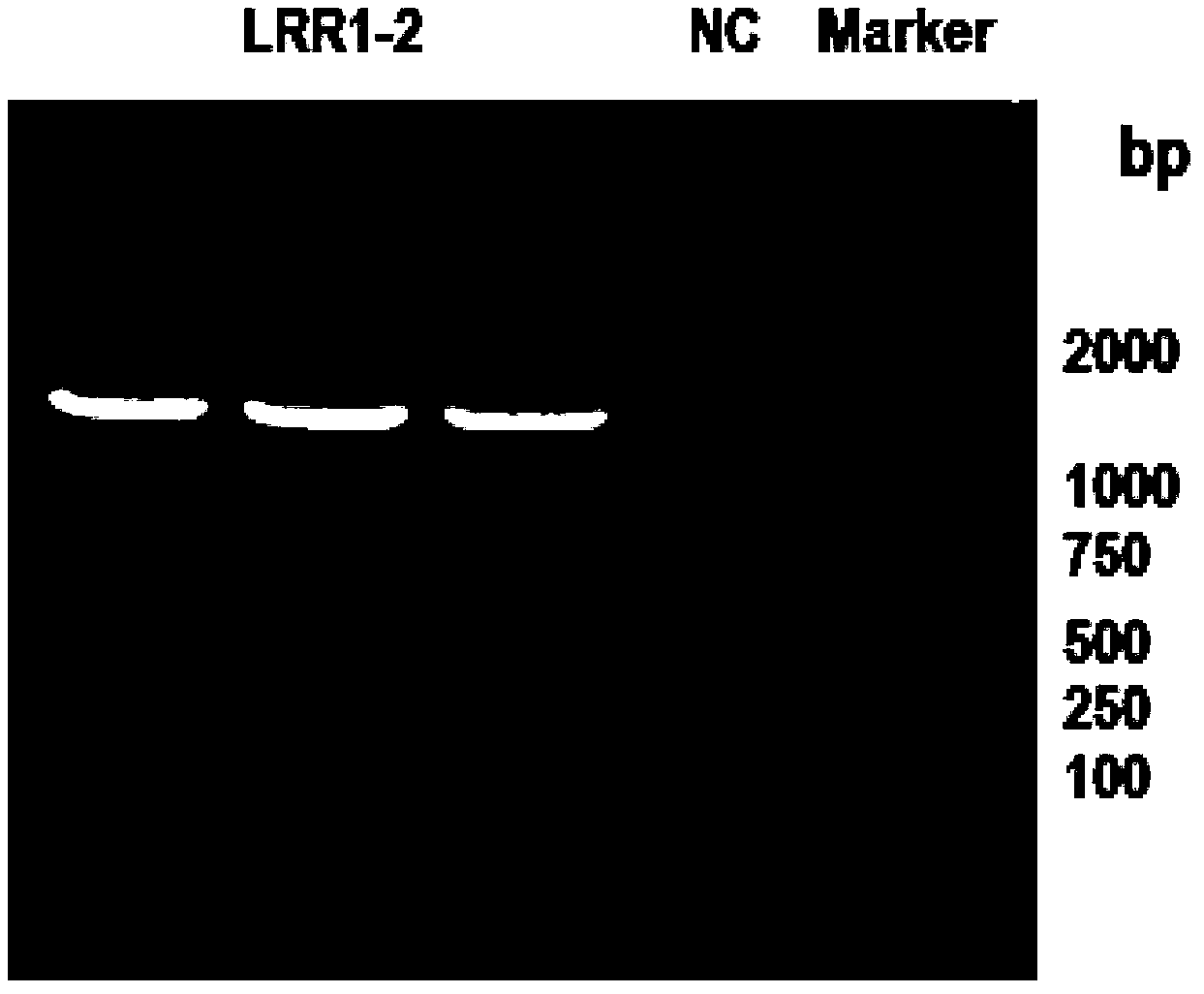

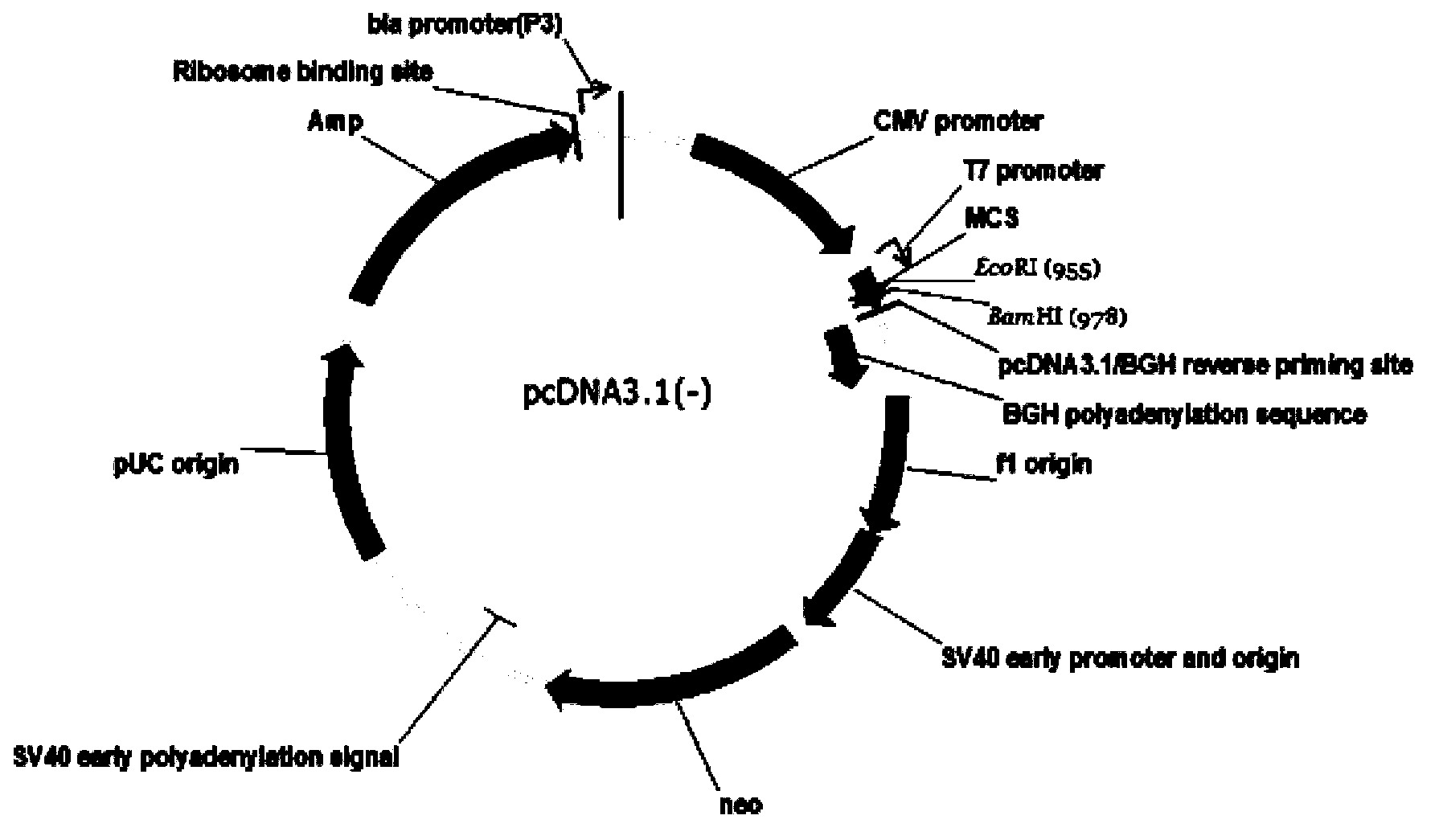

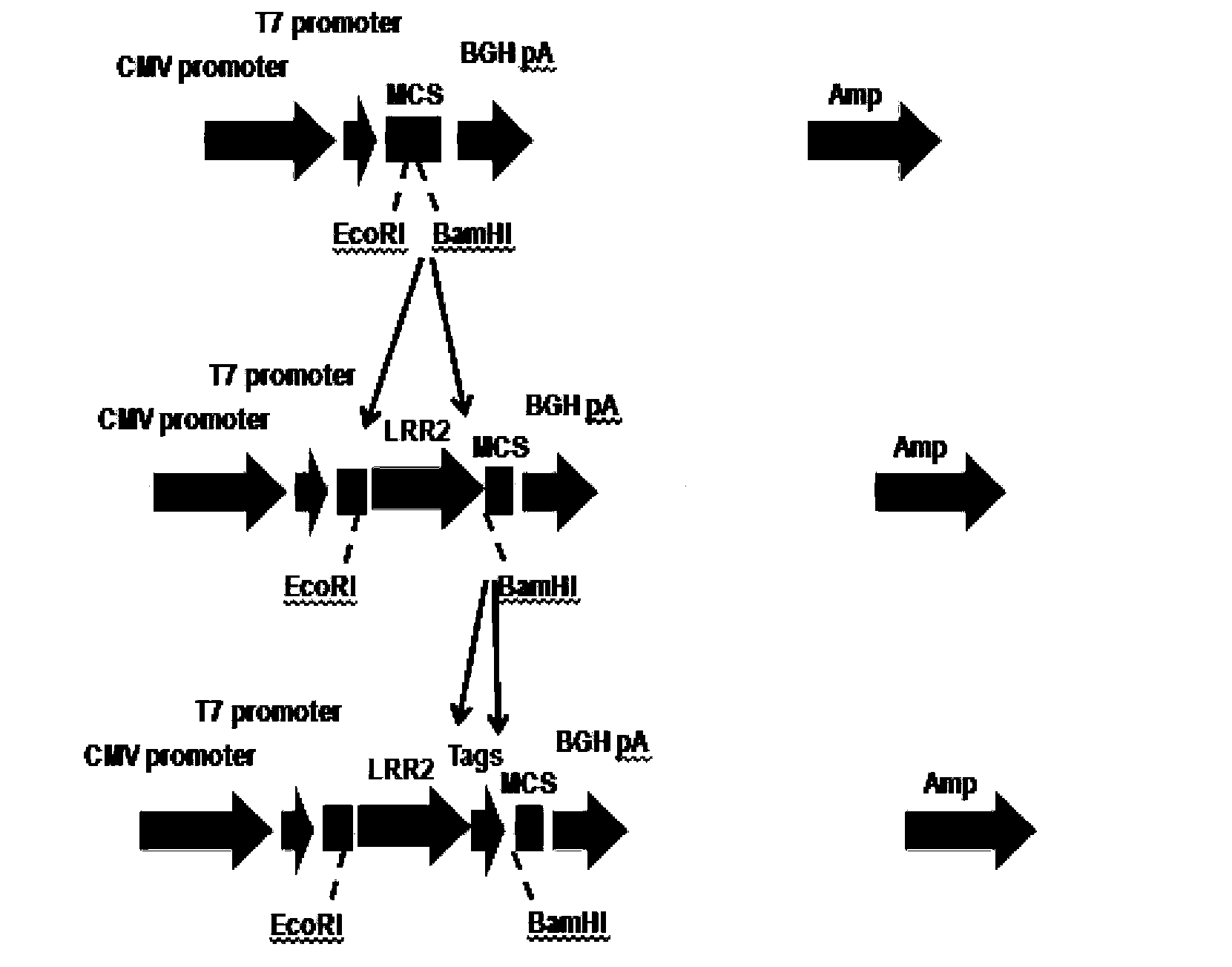

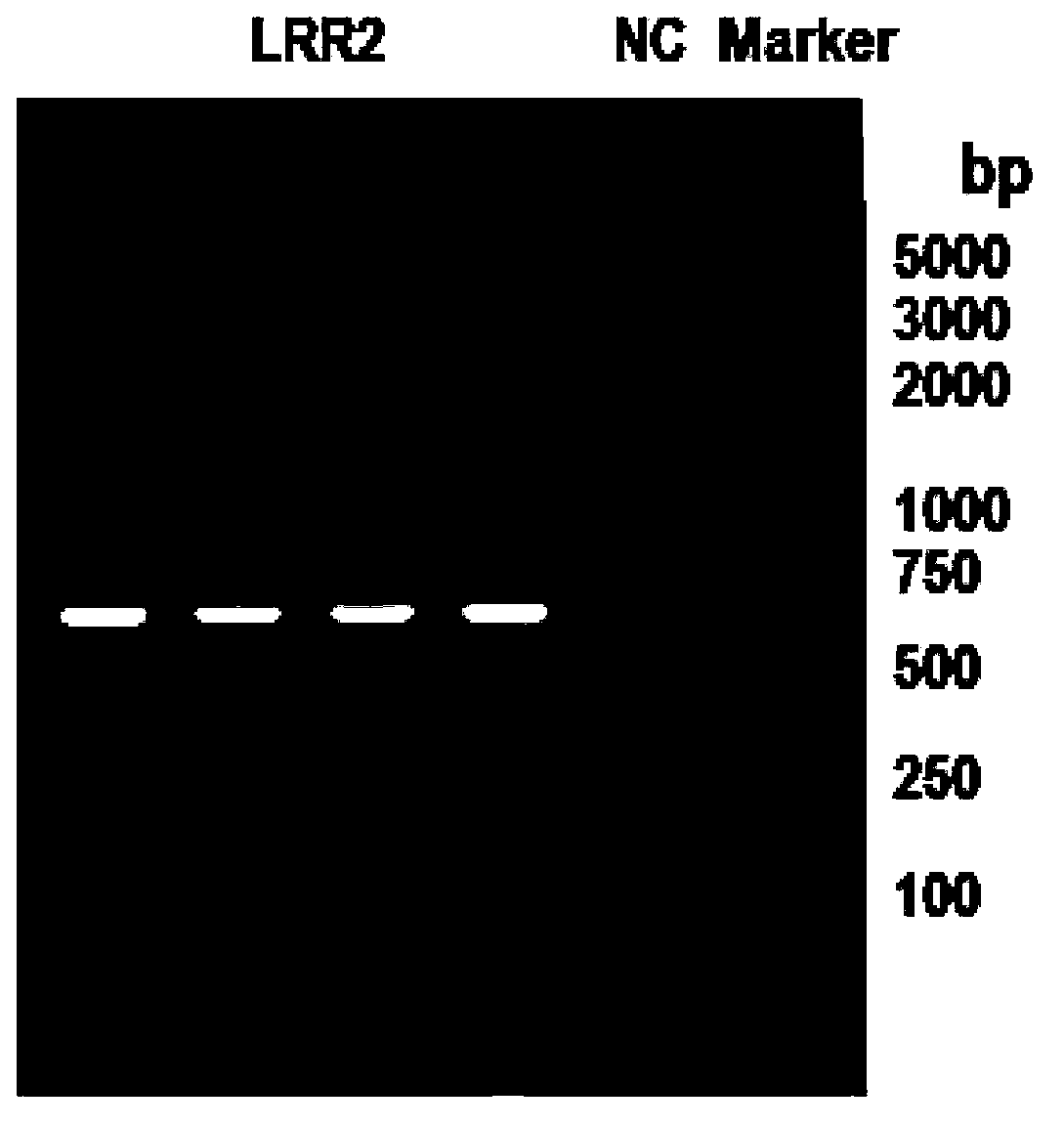

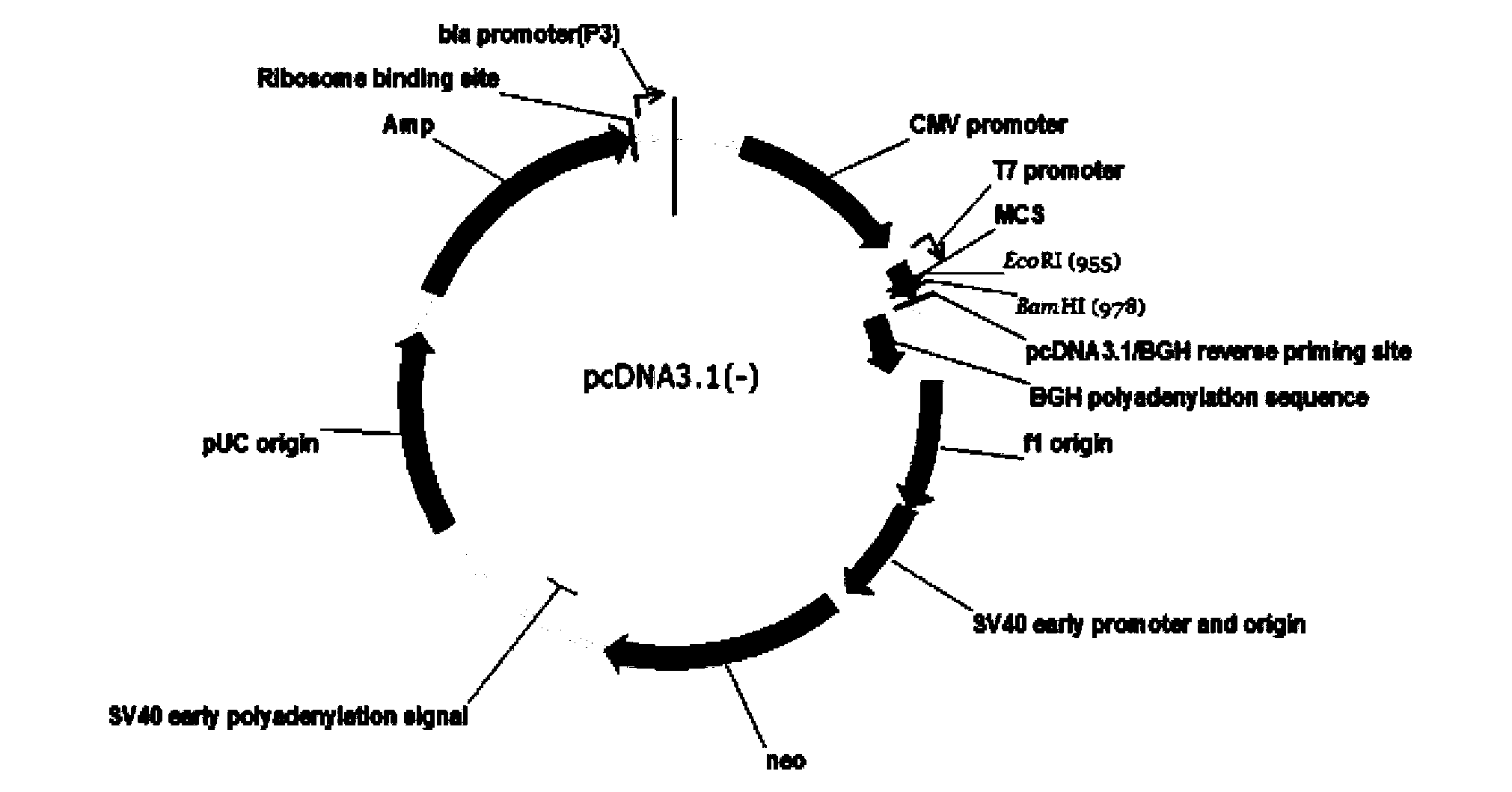

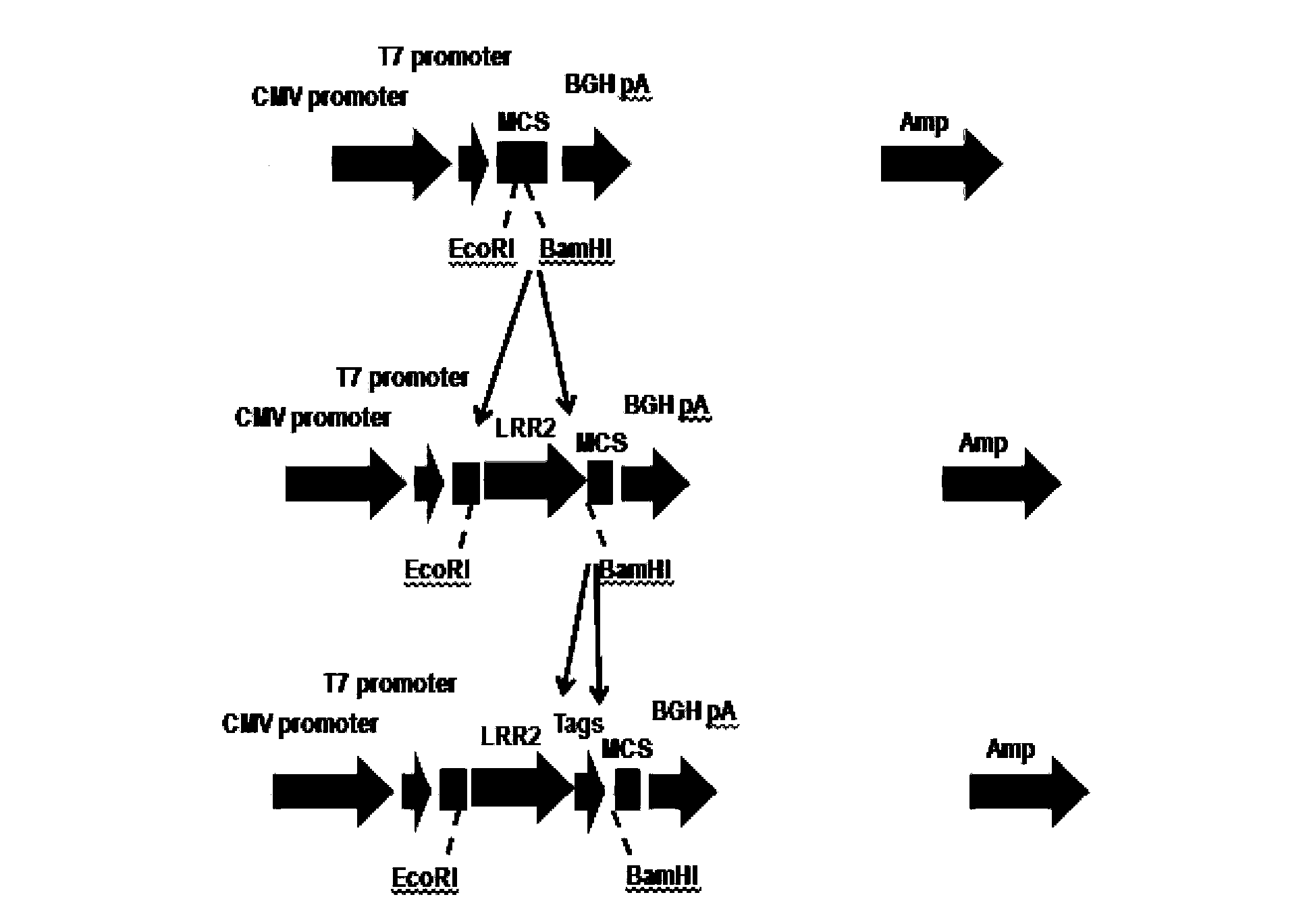

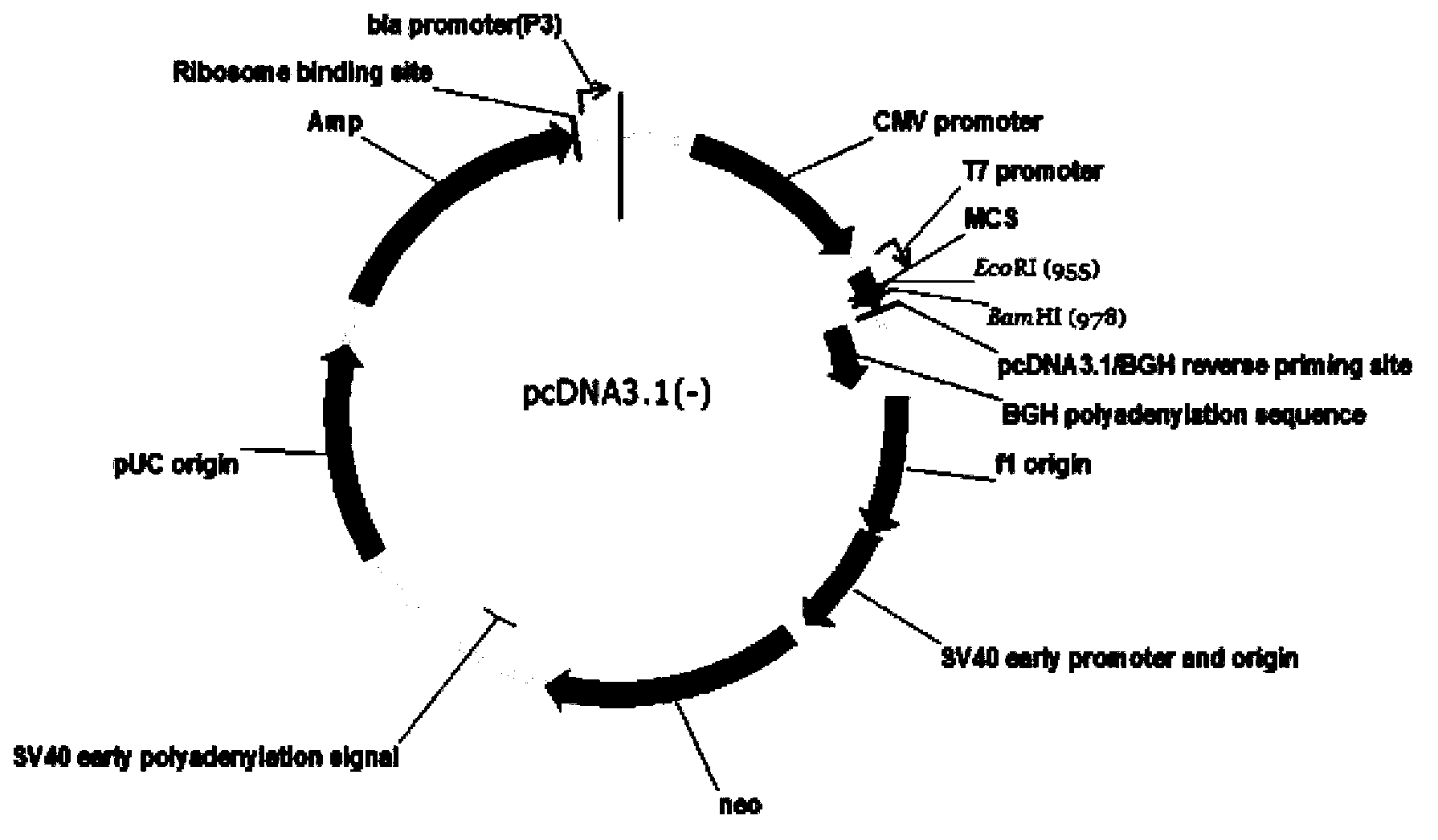

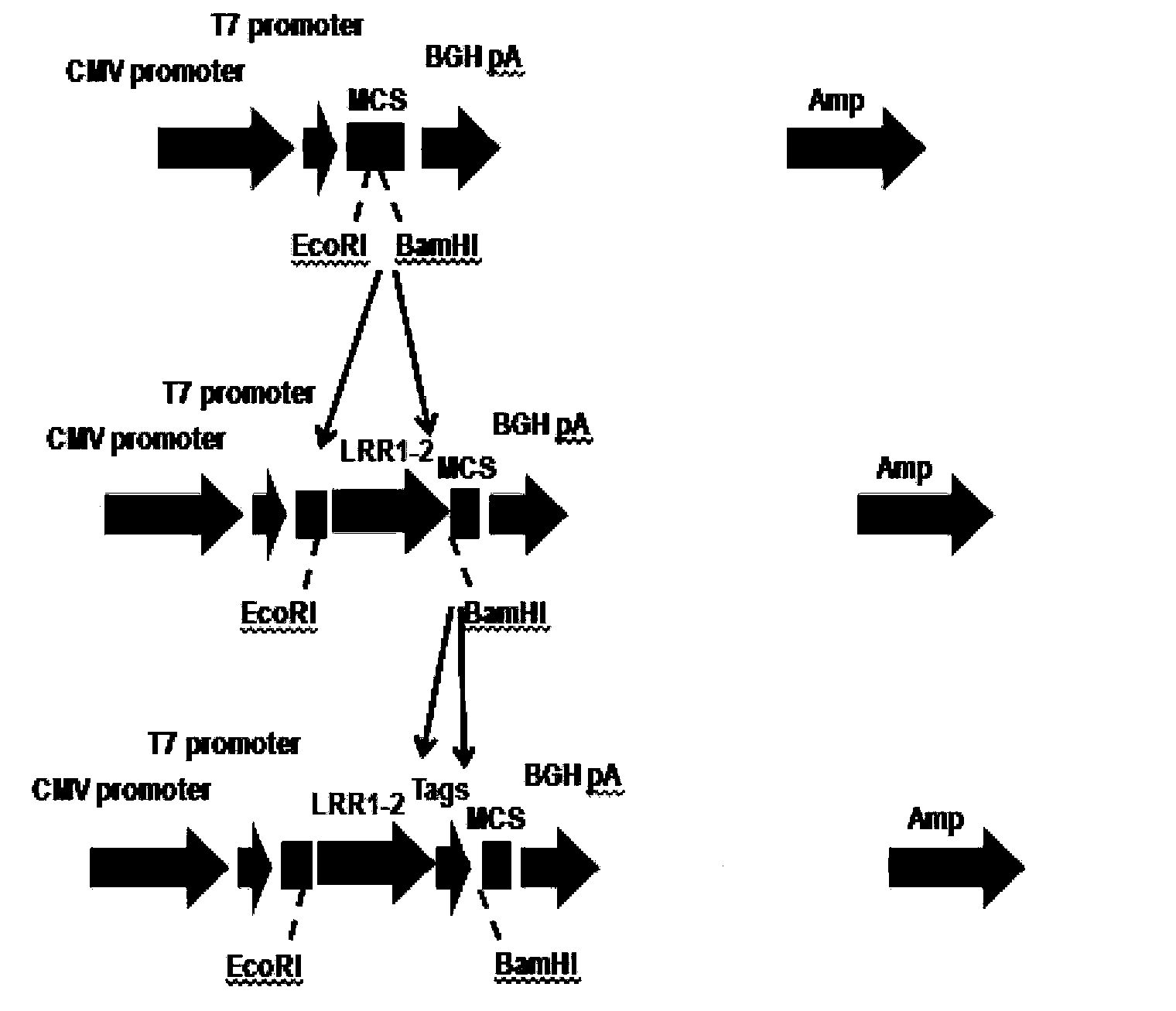

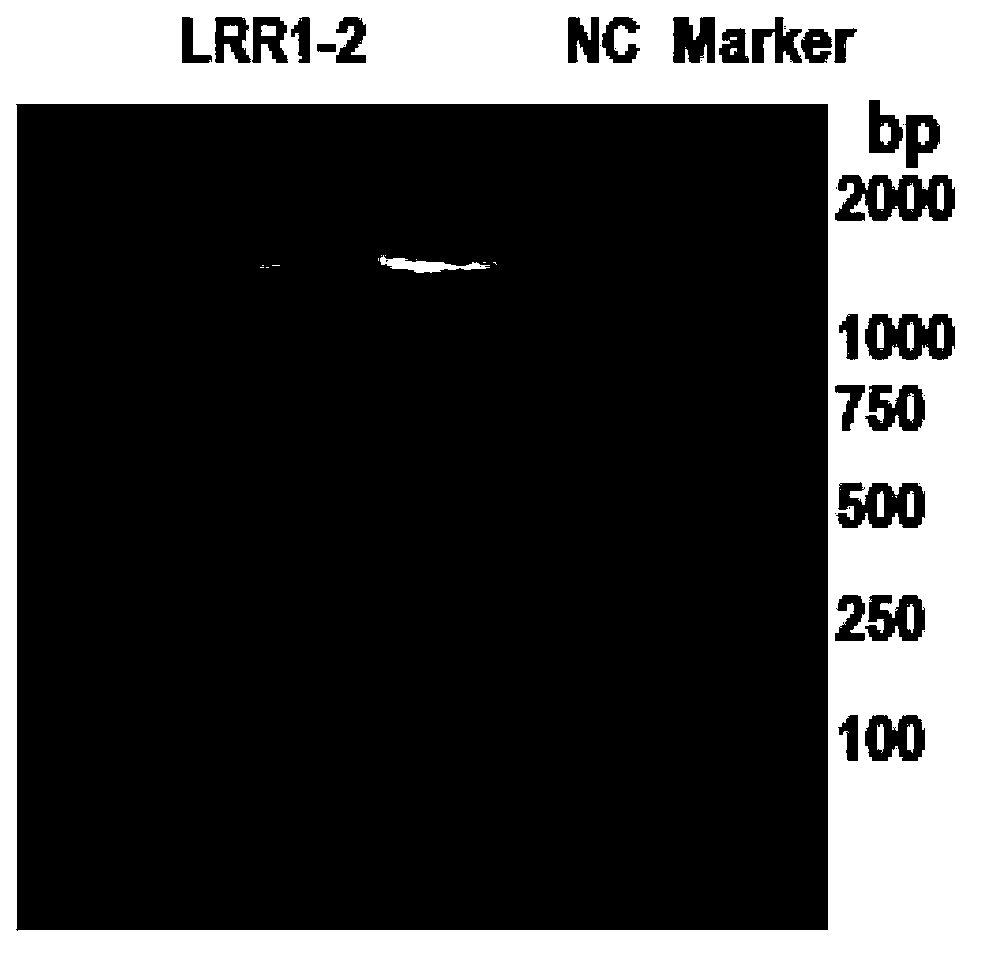

Fusion protein containing leucine-rich repetitive sequence, and preparation method and application thereof

InactiveCN104119445AEfficient and convenient productionFermentationHybrid peptidesSlit2 proteinTert-leucine

The invention discloses fusion protein containing a leucine-rich repetitive sequence, and a preparation method and application thereof. Concretely, the invention relates to fusion protein, and the fusion protein possesses the following structure from N terminal to C terminal: A-X-E-Y1-Y2 (formula Ia) or A-Y2-Y1-E-X (formula Ib), wherein A is an optional secretion signal peptide, X is a member rich in leucine repetitive sequence 1-2 (LRRs1-2) of Slit2 protein (neuronal guidance factor 2), E is a restriction enzyme cutting site, Y1 is a first tag peptide member, Y2 is a second tag short peptide member and the second tag short peptide member is His tag member, and '-' represents a peptide bond or a peptide joint for connecting the above members. The fusion protein is beneficial for correct folding of LRR (leucine-rich repeat) and forming active functional polypeptide, and is capable of simply removing two tag members through once resection enzyme cutting, thereby preparing high-purity high-activity LRR sequence.

Owner:李华顺

Compositions for stabilizing chlorinated water to sunlight decomposition, and methods of preparation thereof

ActiveUS7728132B2Process stabilityLow viscosityOrganic chemistryOther chemical processesDecompositionSlurry

The invention includes a composition for stabilizing chlorinated water to sunlight decomposition, and methods of preparing compositions. The composition is a slurry composition of a monoalkali metal cyanurate, of low viscosity. Two methods of preparing the slurry are described, in which cyanuric acid or cyanuric acid wetcake is mixed with a monoalkali metal base. One method dry blends cyanuric acid or cyanuric acid wetcake with a monoalkali metal base. The invention also describes a method of preparing a dry, solid monoalkali metal cyanurate.

Owner:ENVIRO TECH CHEM SERVICES

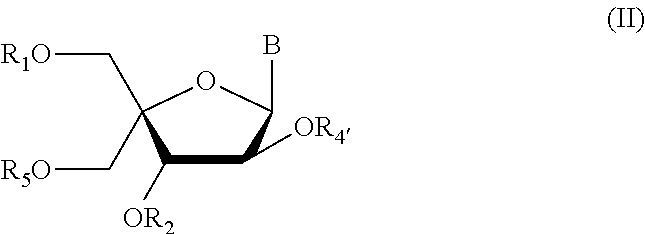

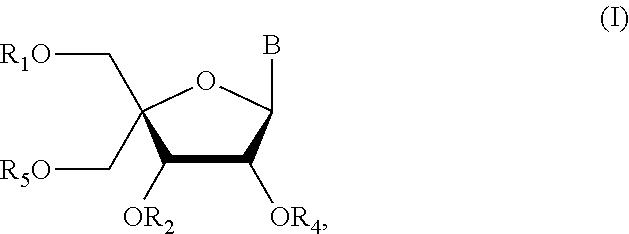

Method for synthesizing nucleic acid

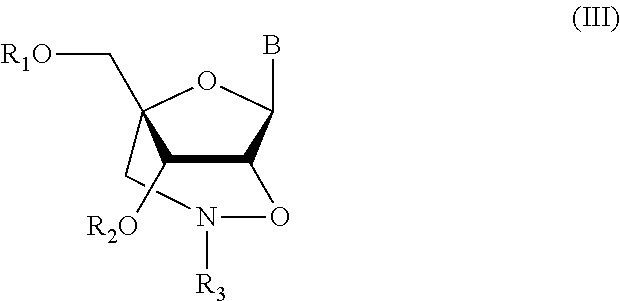

InactiveUS20120108800A1Type efficiently and convenientlyHigh yieldSugar derivativesSugar derivatives preparationCombinatorial chemistryMethods of production

Provided is a new production method for the synthesis of an NC type nucleoside efficiently and conveniently in a high yield without unnecessary protecting group conversion steps. It relates to a step of producing a compound represented by the formula (II):or a salt thereof, by inverting a compound represented by the formula (I):and a method of producing a compound represented by the formula (III):or a salt thereof (wherein each symbol is as defined in the specification), which includes the step.

Owner:TAKEDA PHARMA CO LTD

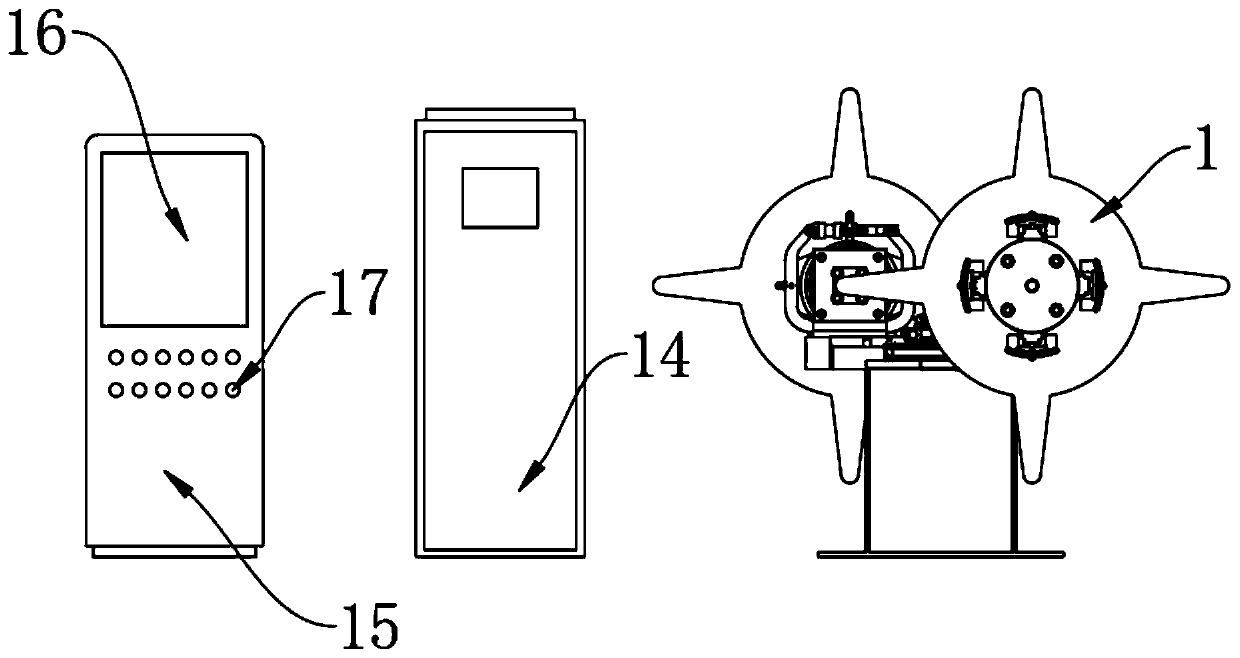

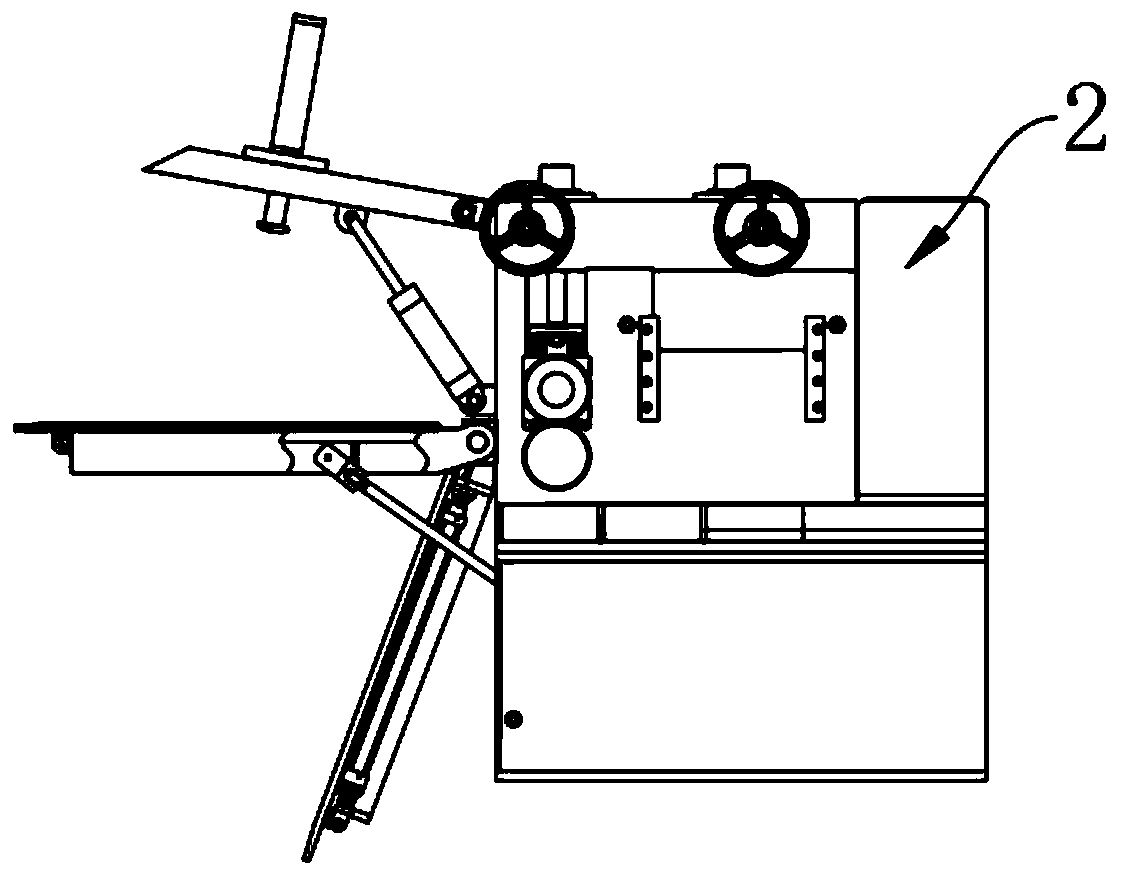

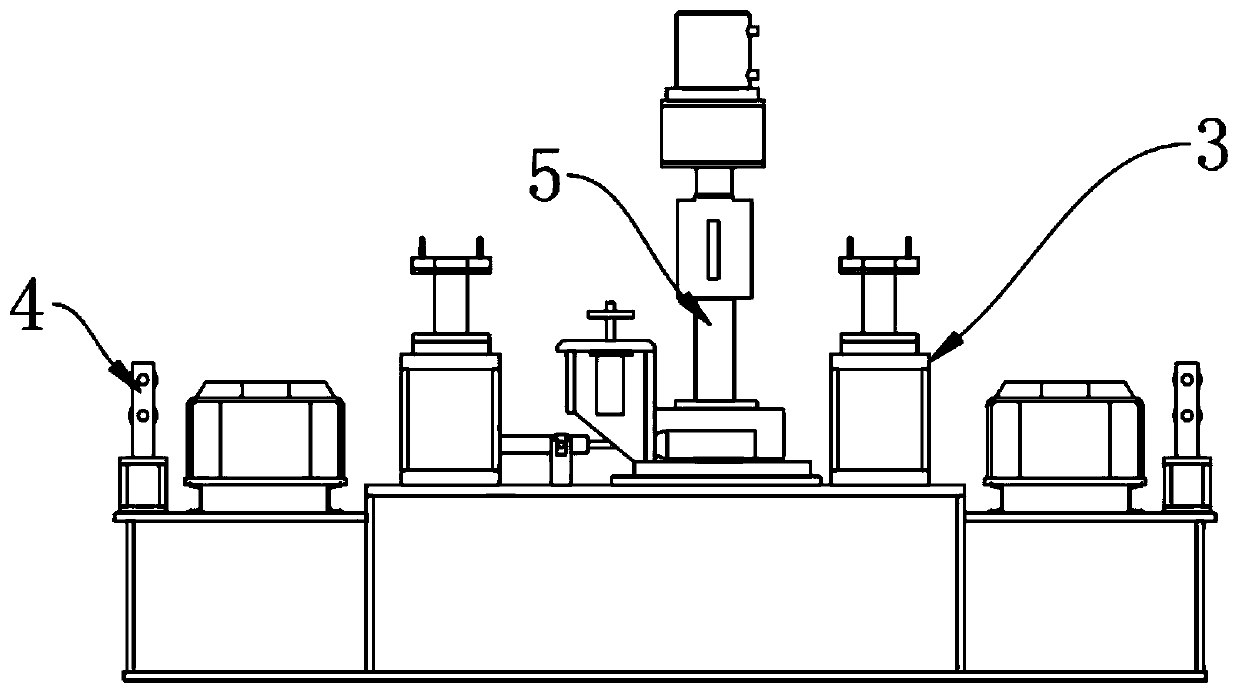

High-speed structural steel intelligent production line

PendingCN110014331AHigh degree of automationReduce labor intensityMetal working apparatusProduction linePunching

The invention discloses a high-speed structural steel intelligent production line, and relates to the technical field of intelligent control automation. In order to solve the problems that a high-speed structural steel production line is many in production working procedure, high in manual cost and low in work efficiency, the production line is provided. A flattening machine is arranged on one side of a dual-head uncoiling machine, an automatic shearing butt welding machine is arranged on the other side of the flattening machine, pinch devices are arranged on the two ends of the automatic shearing butt welding machine, a shear welding device is arranged in the middle of the automatic shearing butt welding machine, a horizontal spiral loop is arranged on the other side of the automatic shearing butt welding machine, a punching mechanism is arranged on the other side of the horizontal spiral loop, a forming main engine is arranged on the other side of the punching mechanism, a hydrauliccutting-off mechanism is arranged on the other side of the forming main engine, a stacking mechanism is arranged on the other side of the hydraulic cutting-off mechanism, a packaging mechanism is arranged on the other side of the stacking mechanism, and a full-automatic packaging machine is arranged at one end of the packaging mechanism.

Owner:ARCTECH SOLAR CHANGZHOU CO LTD

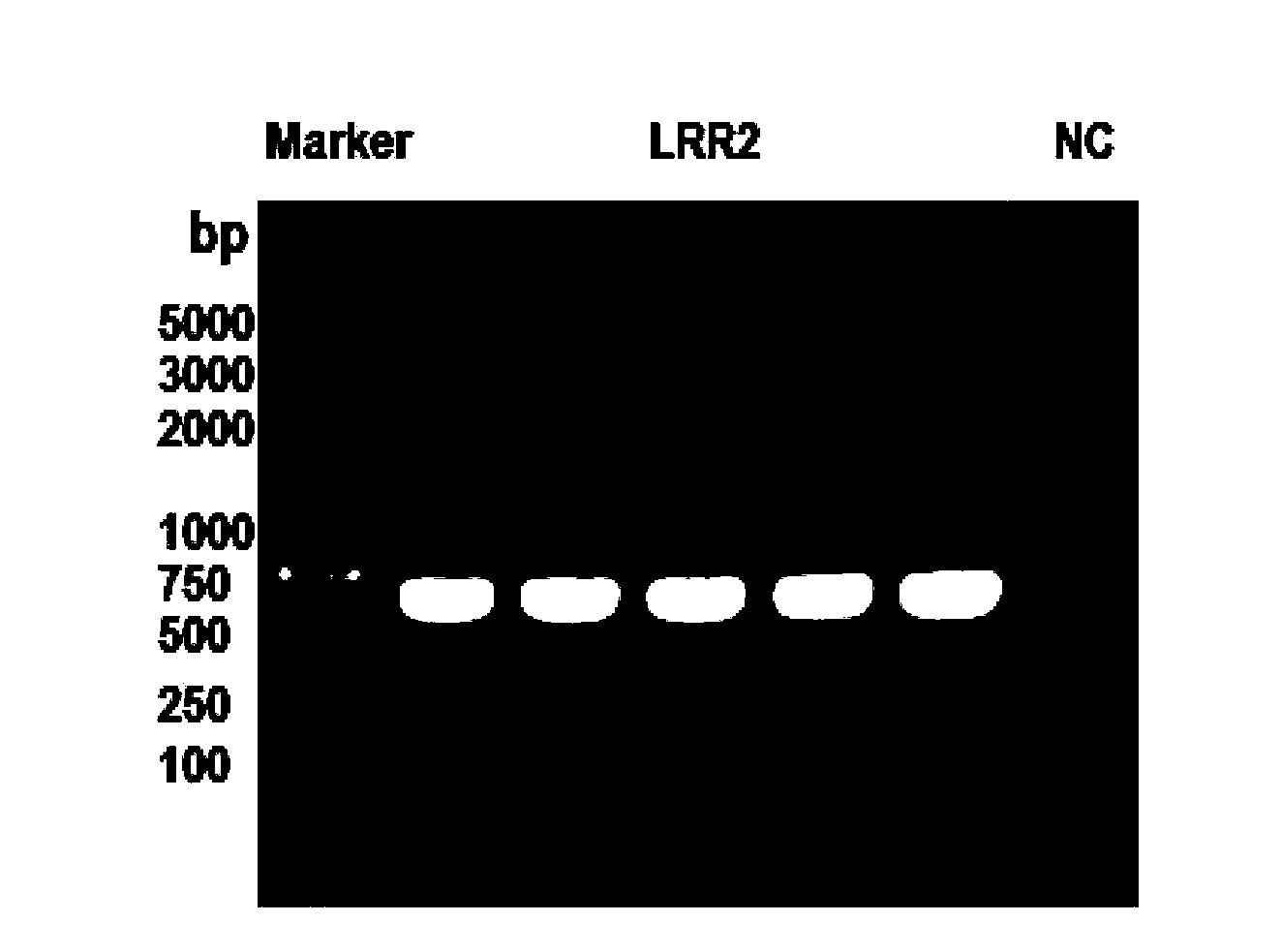

Fusion protein containing leucine-rich repetitive sequence, and preparation method and application thereof

InactiveCN104119447AEfficient and convenient productionMicroorganism based processesArtificial cell constructsSlit2 proteinTert-leucine

The invention discloses fusion protein containing a leucine-rich repetitive sequence, and a preparation method and application thereof. Concretely, the invention relates to fusion protein, and the fusion protein possesses the following structure from N terminal to C terminal: A-X-E-Y1-Y2 (formula Ia) or A-Y2-Y1-E-X (formula Ib), wherein A is an optional secretion signal peptide, X is a member rich in leucine repetitive sequence 2 (LRRs2) of Slit2 protein (neuronal guidance factor 2), E is a restriction enzyme cutting site, Y1 is a first tag peptide member, Y2 is a second tag short peptide member and the second tag short peptide member is His tag member, and '-' represents a peptide bond or a peptide joint for connecting the above members. The fusion protein is beneficial for correct folding of LRR (leucine-rich repeat) and forming active functional polypeptide, and is capable of simply removing two tag members through once resection enzyme cutting, thereby preparing high-purity high-activity LRR sequence.

Owner:李华顺

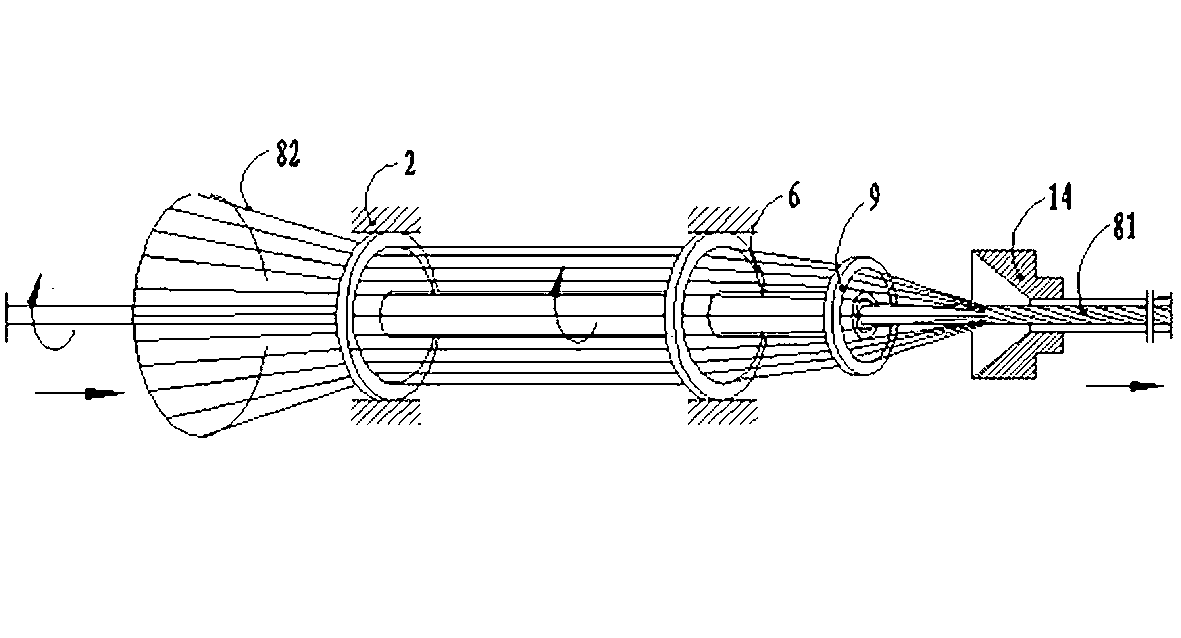

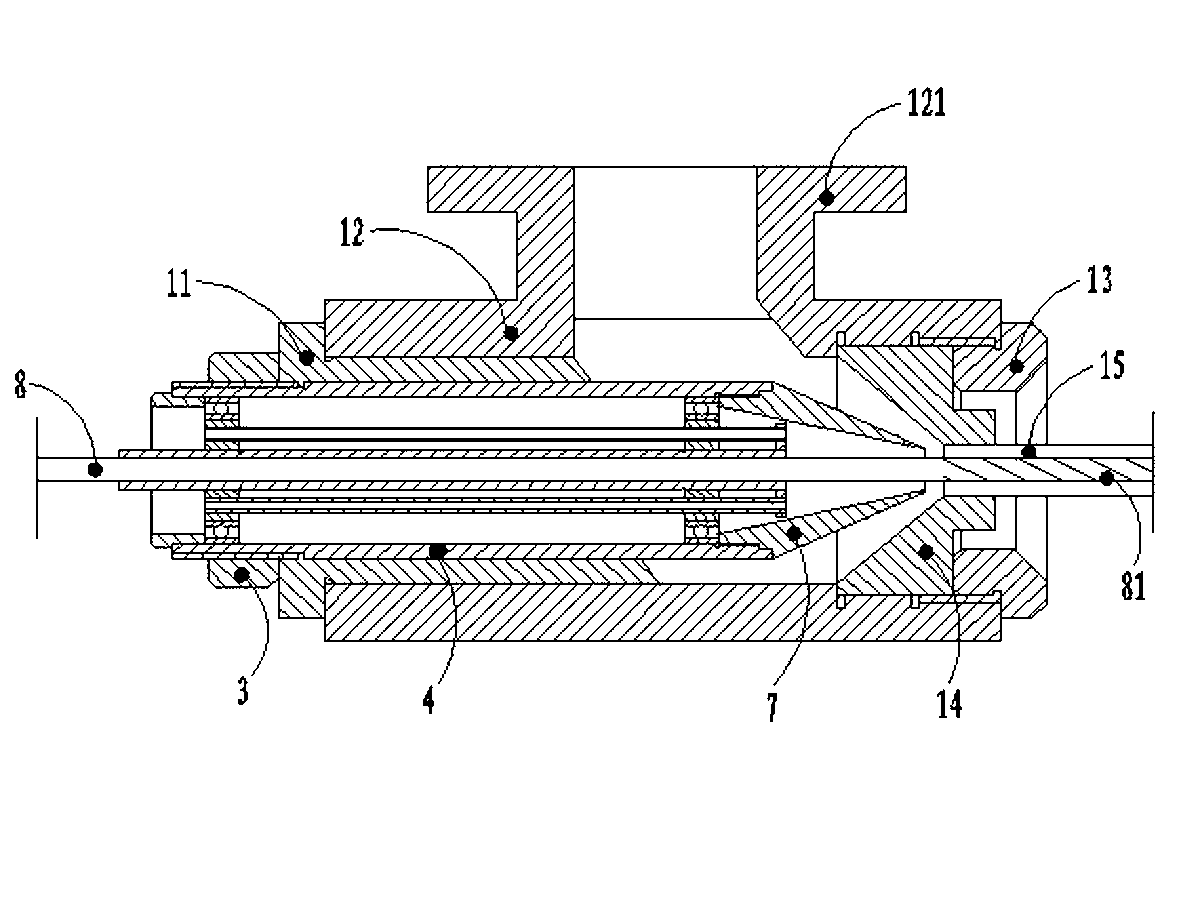

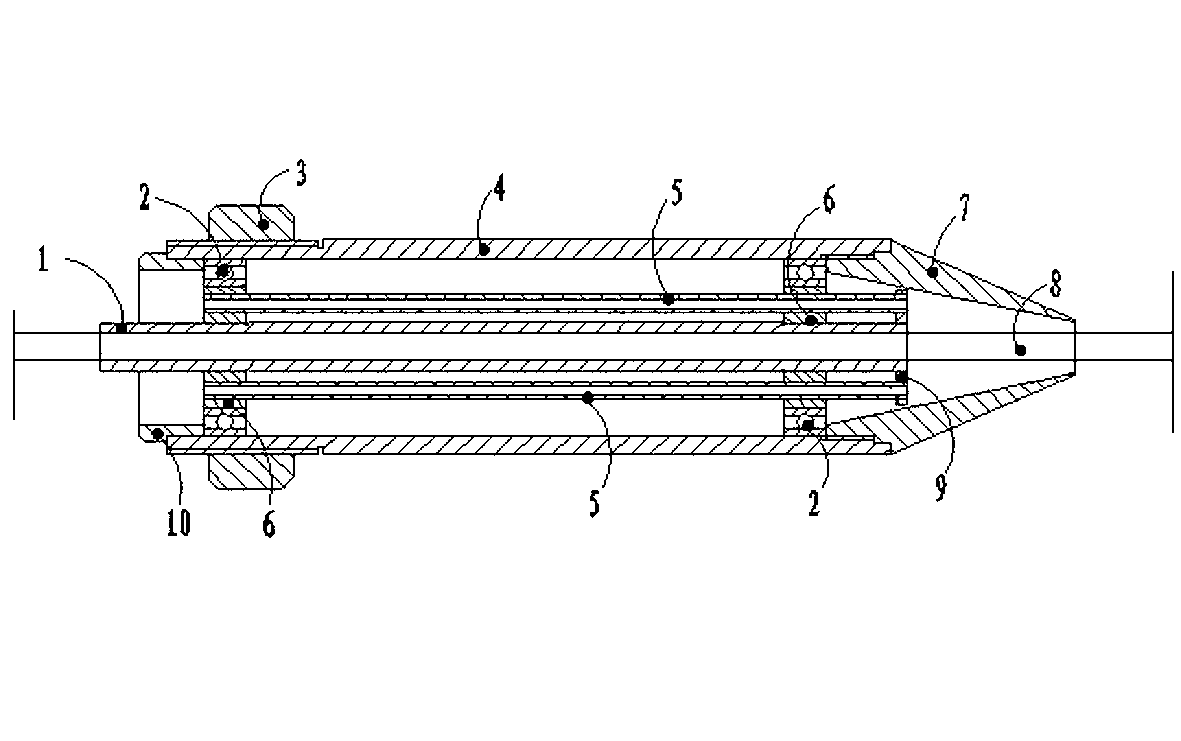

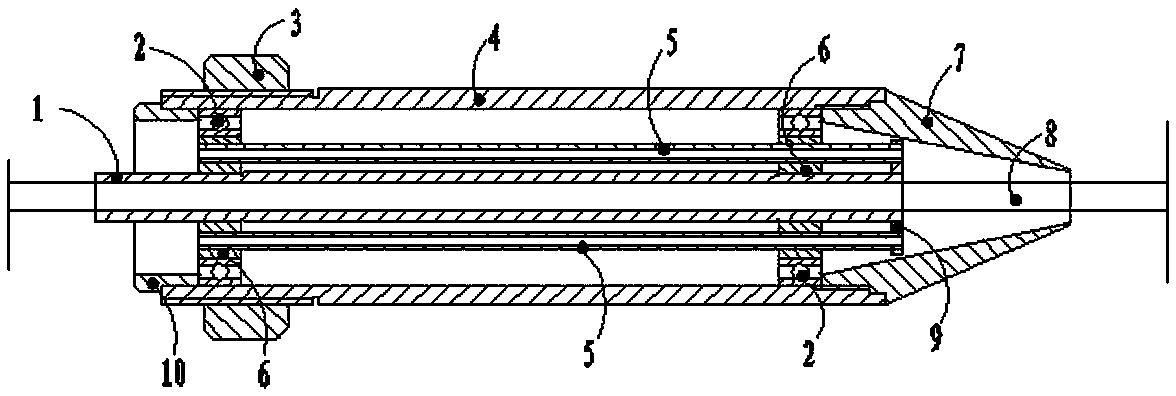

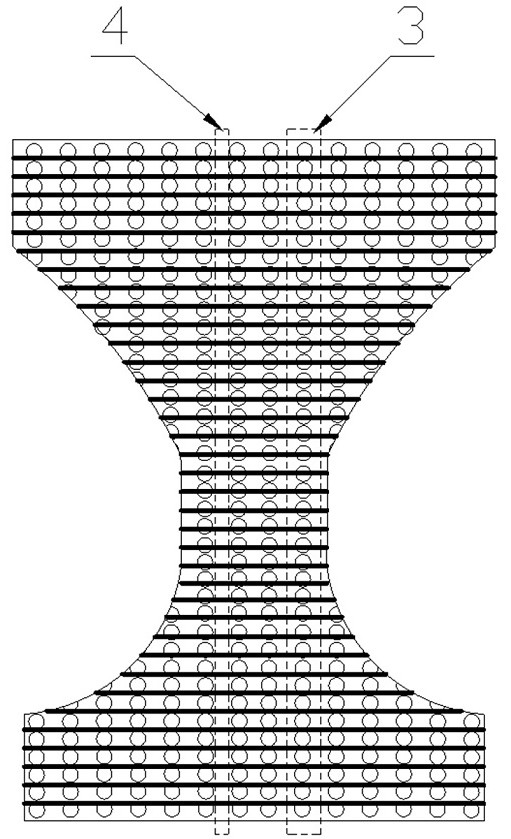

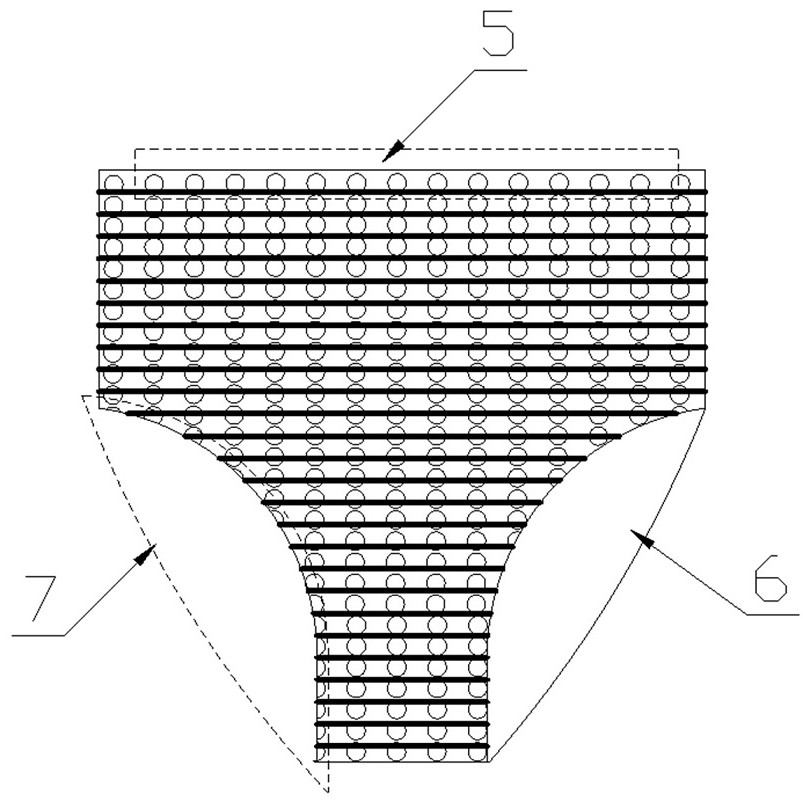

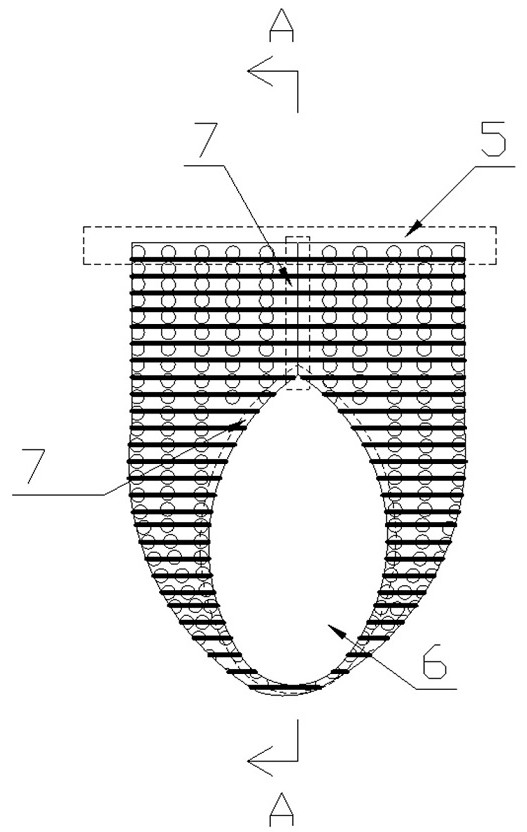

Plastic extruding mould for producing electric cables

ActiveCN103341960ASolve the poor uniformity of the gap distribution of the wrapped single wireLow manufacturing costStructural engineeringManufacturing engineering

The invention relates to the electric wire and electric cable manufacture field, and particularly to a plastic extruding mould required by production of a concentric sparse winding shielding layer of a plurality of single-wire conductors under a cable sheath layer. Disclosed is the plastic extruding mould for producing electric cables. The plastic extruding mould includes a plastic extruding mould base; a male mould and a female mould are respectively arranged at two sides of a cavity in the plastic extruding mould base, a mould cavity is formed between the male mould and the female mould, the female mould is connected with a forming pipe, and the male mould is connected with a mould body; the interior of the mould body is connected with a stranding cage through bearings, the interior of the stranding cage is provided with a threading pipe, the stranding cage can rotate around the threading pipe, the right end of the stranding cage is provided with a distributing terminal board, and the distributing terminal board is provided with wire harness conduits. A wire core is passed through the threading pipe, then through the male mould and the female mould, next through the forming pipe, and is connected with a traction machine set; and sparse winding single wires are passed through the wire harness conduits and the distributing terminal board.

Owner:SICHUAN JIUZHOU WIRE & CABLE

Fusion protein containing leucine-rich repetitive sequence, and preparation method and application thereof

InactiveCN104119448AEfficient and convenient productionFermentationHybrid peptidesTert-leucineC-terminus

The invention discloses fusion protein containing a leucine-rich repetitive sequence, and a preparation method and application thereof. Concretely, the invention relates to fusion protein, and the fusion protein possesses the following structure from N terminal to C terminal: A-X-E-Y1-Y2 (formula Ia) or A-Y2-Y1-E-X (formula Ib), wherein A is an optional secretion signal peptide, X is a member rich in leucine repetitive sequence 2 (LRRs2) of Slit3 protein (neuronal guidance factor 3), E is a restriction enzyme cutting site, Y1 is a first tag peptide member, Y2 is a second tag short peptide member and the second tag short peptide member is His tag member, and '-' represents a peptide bond or a peptide joint for connecting the above members. The fusion protein is beneficial for correct folding of LRR (leucine-rich repeat) and forming active functional polypeptide, and is capable of simply removing two tag members through once resection enzyme cutting, thereby preparing high-purity high-activity LRR sequence.

Owner:李华顺

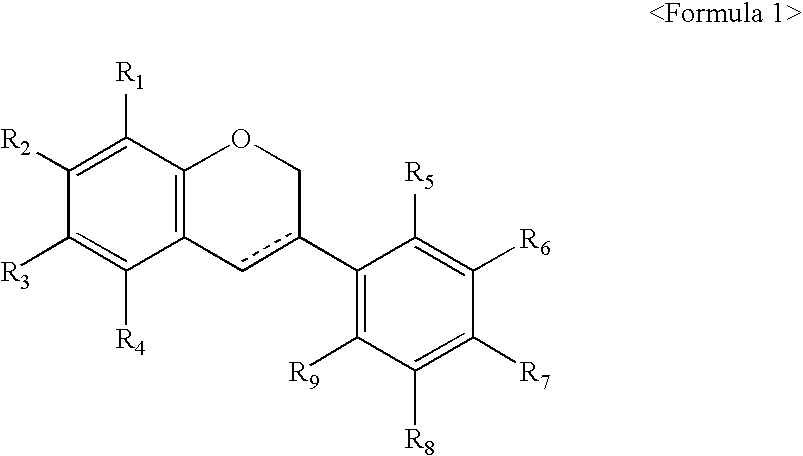

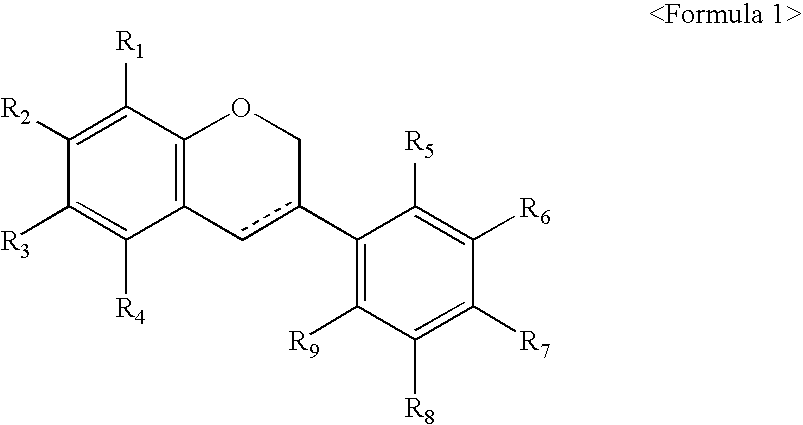

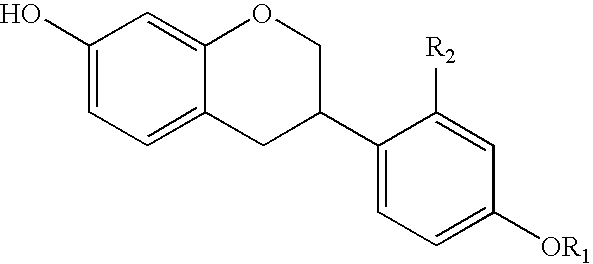

Manufacturing process of isoflavan or isoflavene derivatives

InactiveUS20070037874A1Efficient and convenient productionBiocideOrganic chemistryUltravioletMedicinal chemistry

The present invention relates to a method of synthesizing isoflavan and isoflavene derivatives of the Formula 1, which have the biological efficacy of antioxidation and protection against ultraviolet light. The method is effective and suitable for a mass production of isoflavan and isoflavene derivatives, which is a more convenient alternative preparation method compared to the isolation method by the extraction of plants, such as licorice, via troublesome preparative processes.

Owner:BICBIO

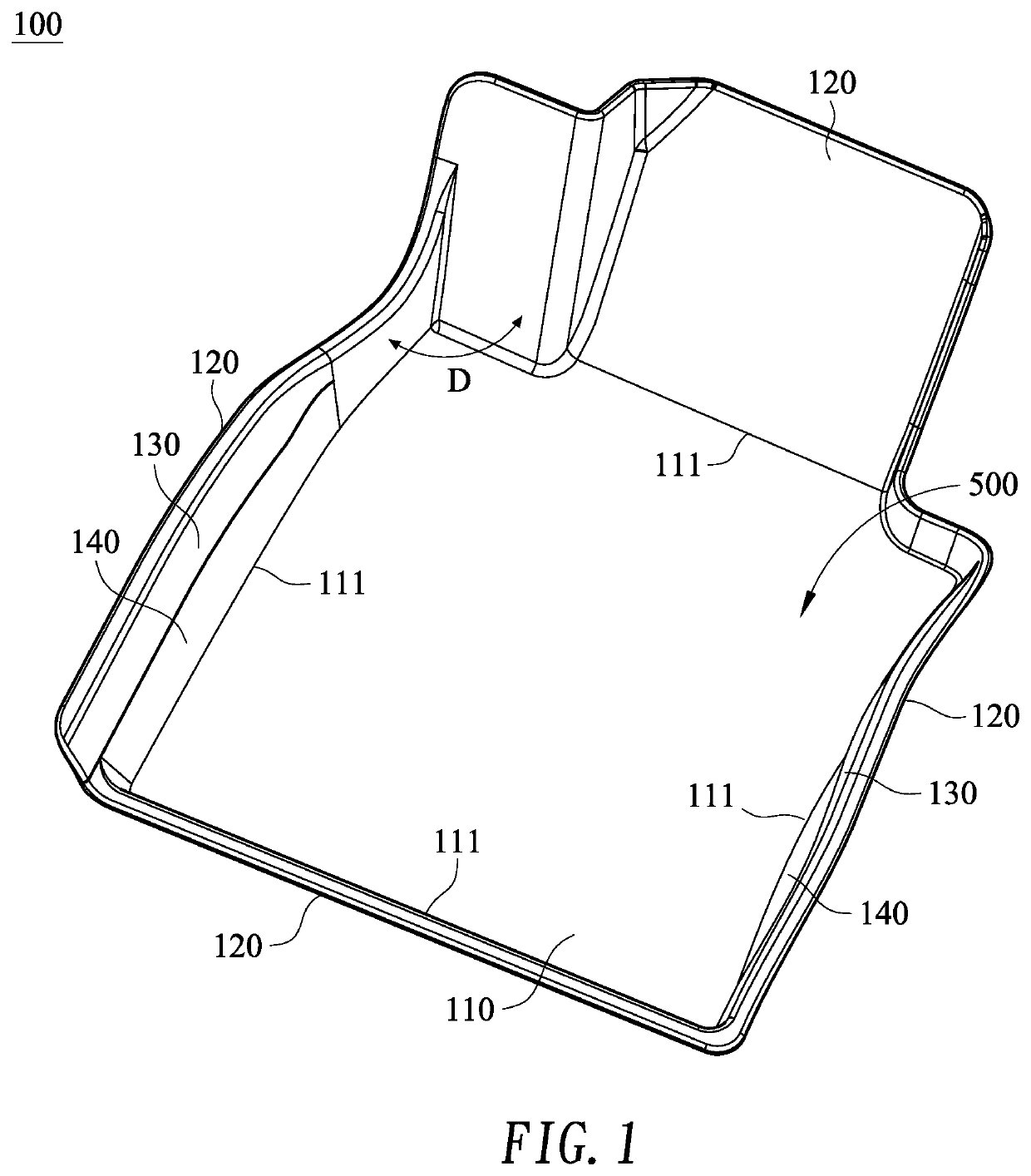

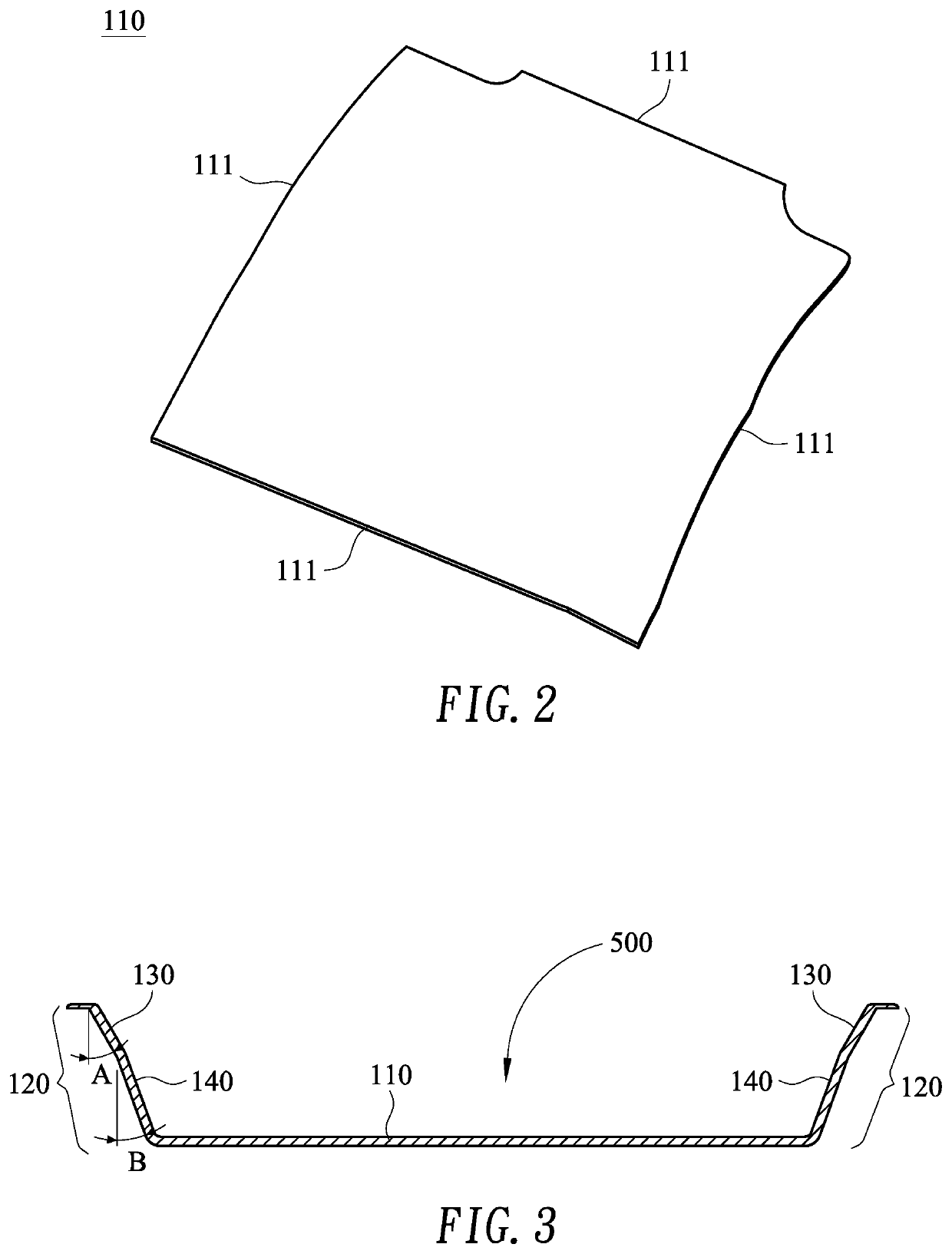

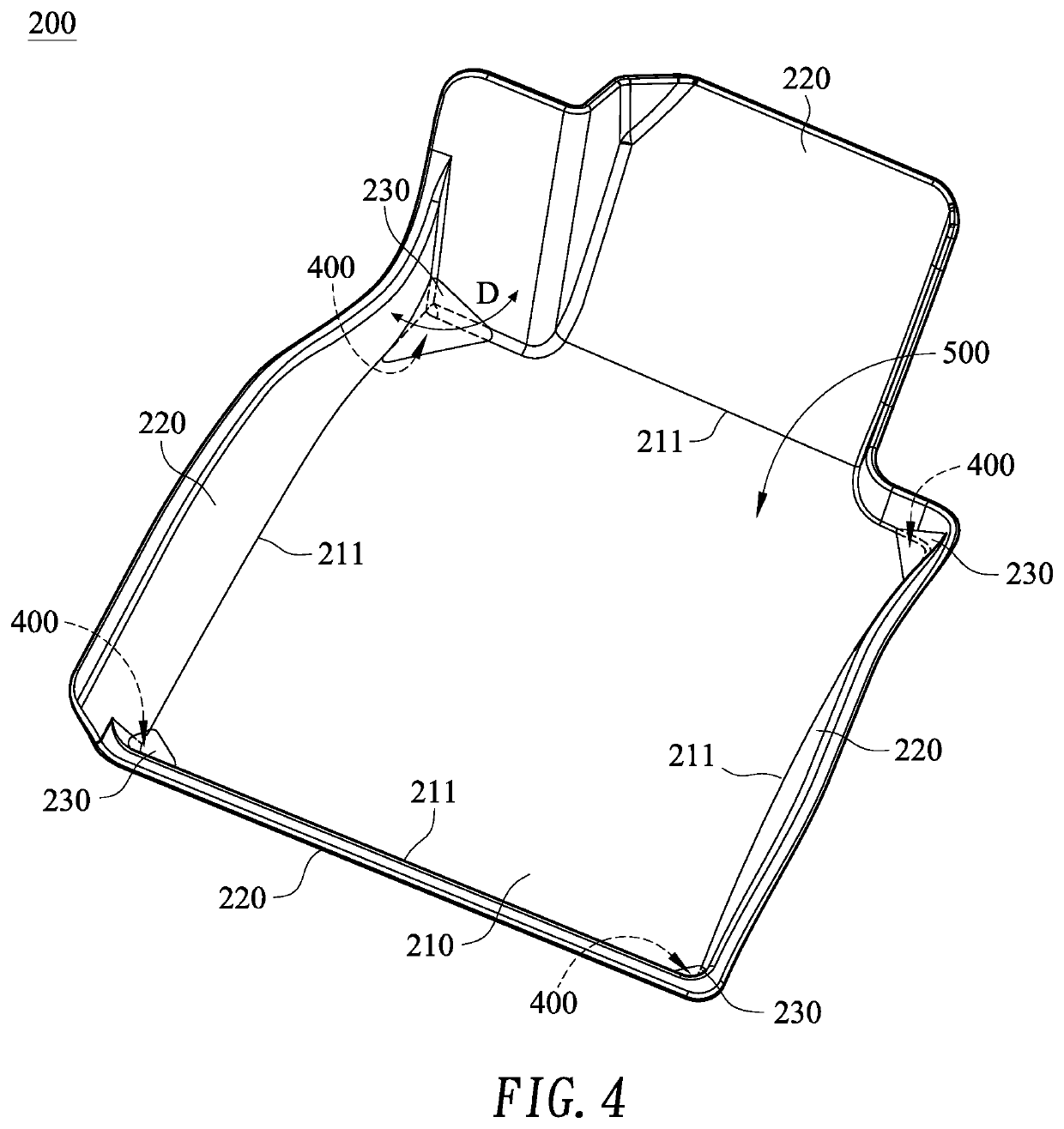

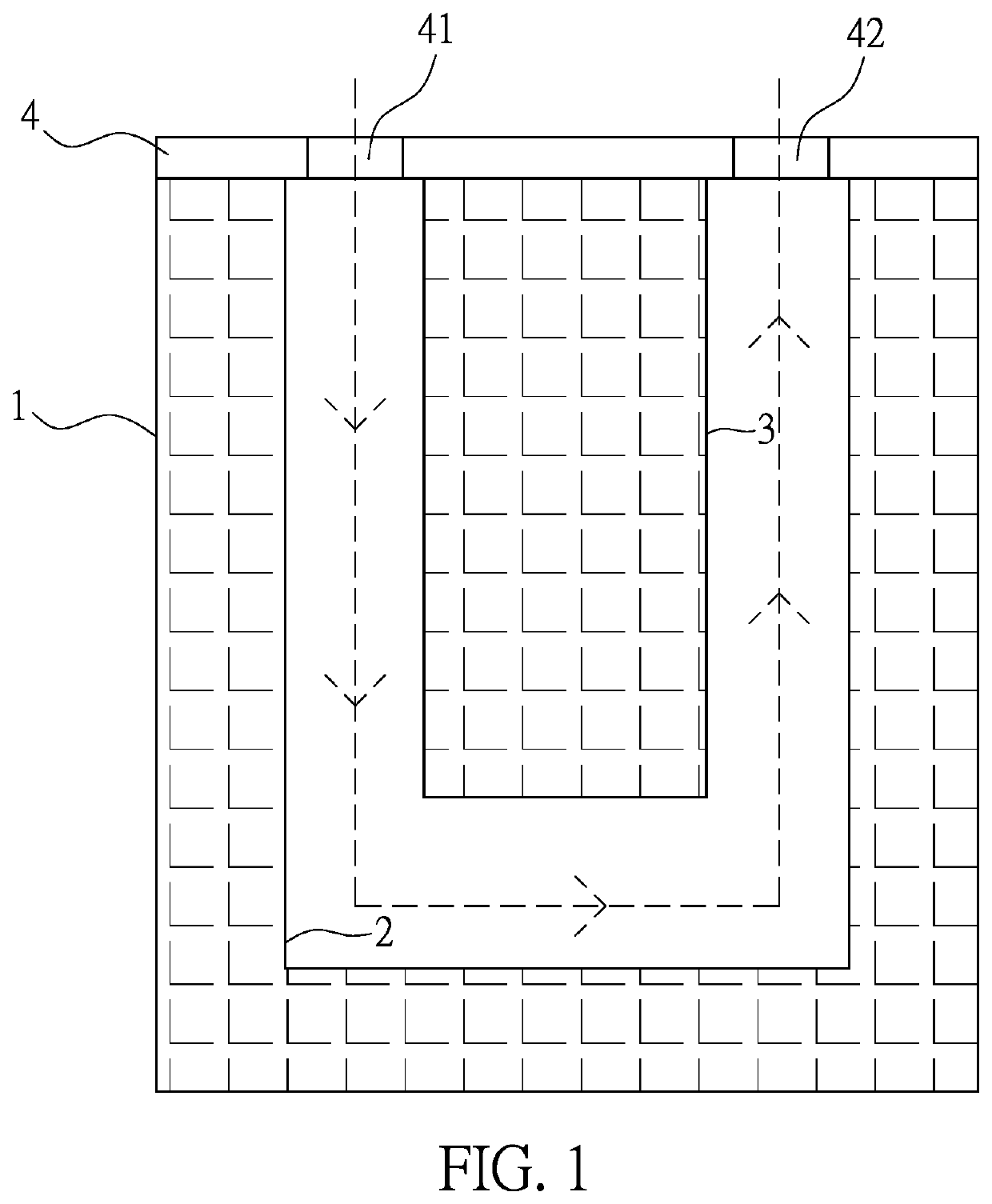

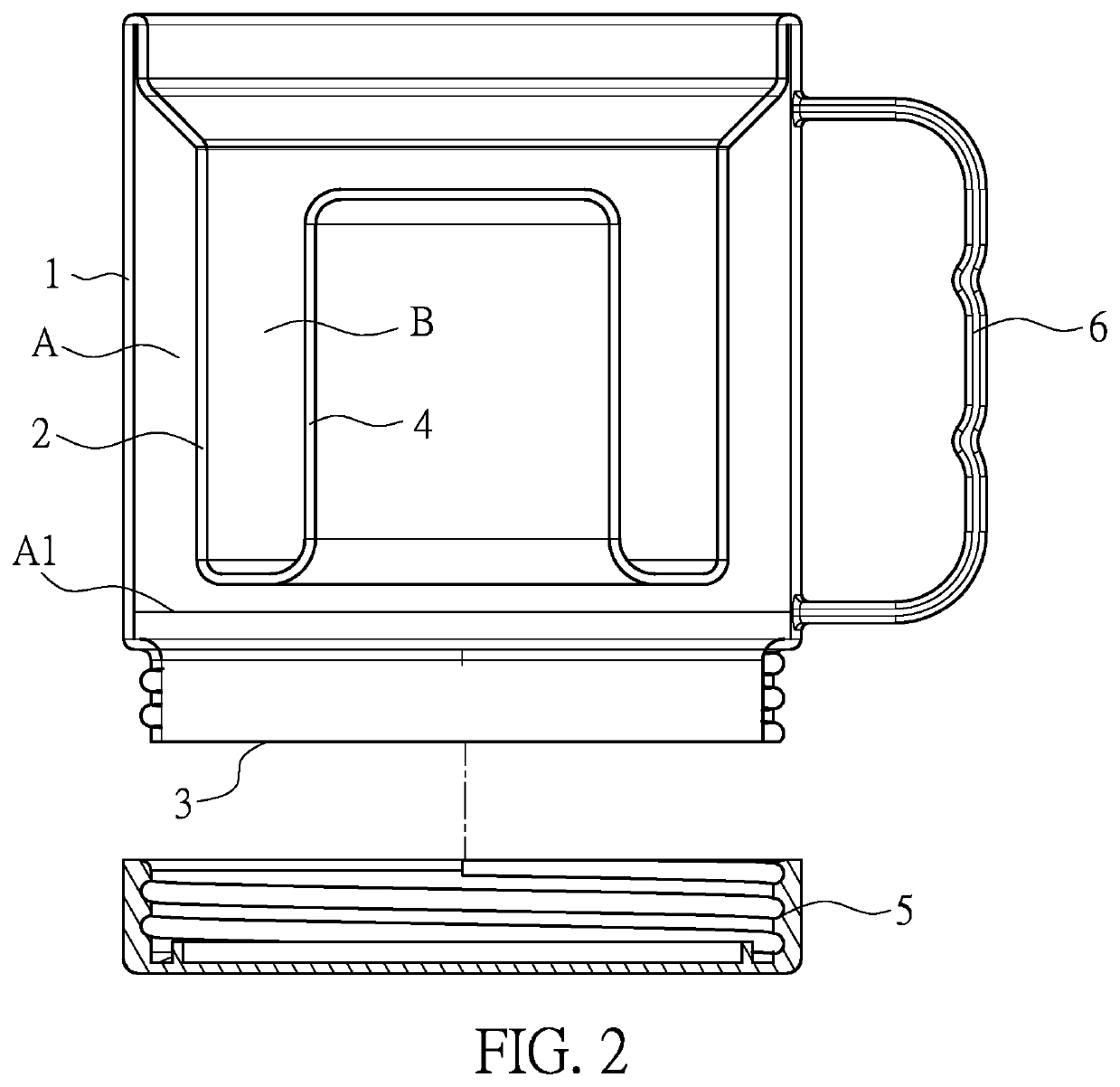

Car Mat Structures

InactiveUS20210237635A1Easy to cleanEfficient and convenient productionVehicle arrangementsLouverStructural engineering

The present invention discloses car mat structures used to set on the floor compartment area in a car to contain water drops or debris fallen or brought into the car. One car mat structure includes a bottom pad with plural sidelines; and plural dams, each being raised from one said sideline, wherein two opposite members of the dams are dual slop walls each being built with two inclined surfaces with different inclined angles. Another car mat structure includes a bottom pad; plural dams raised from the sidelines of the bottom pad; and plural triangle shutters formed to cover bottom corners each formed by two adjacent dams and the bottom pad. A third car mat structure includes a bottom pad; plural dams raised from the sidelines of the bottom pad, wherein two opposite members of the dams each being built with two inclined surfaces with different inclined angles; and plural triangle shutters. With the implementation of the new design dams and triangle shutters of the present invention, molding is easier when forming and producing mat structures; cleaning becomes easier since no hidden corners existing on the mat structures; and deformation or collapsing of mat structures being effectively prevented. When further build an inclined cover pad to cover the junction area between a dam and the bottom pad, molding for production and cleaning the mats become even more convenient and efficient.

Owner:FORMOSA SAINT JOSE

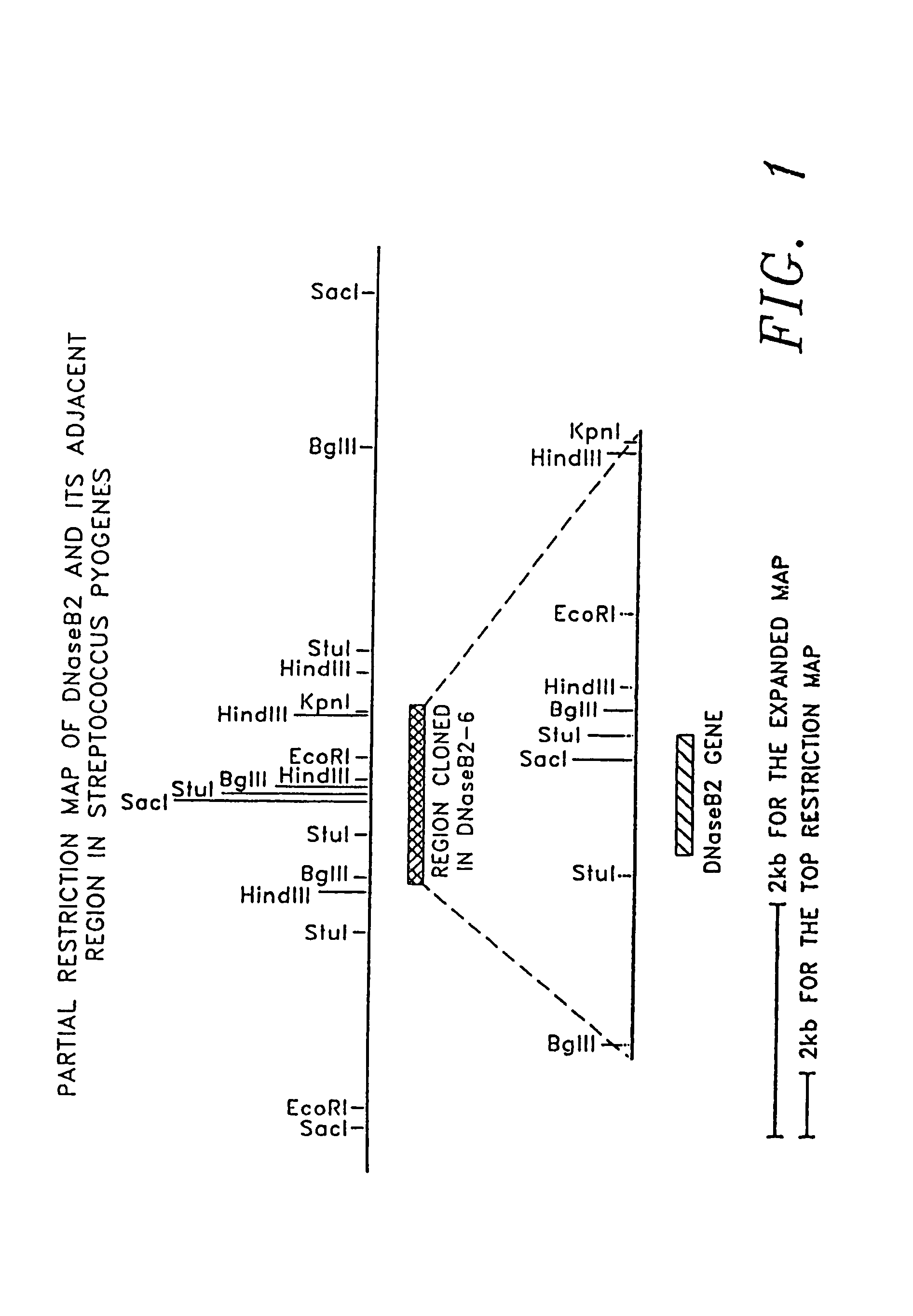

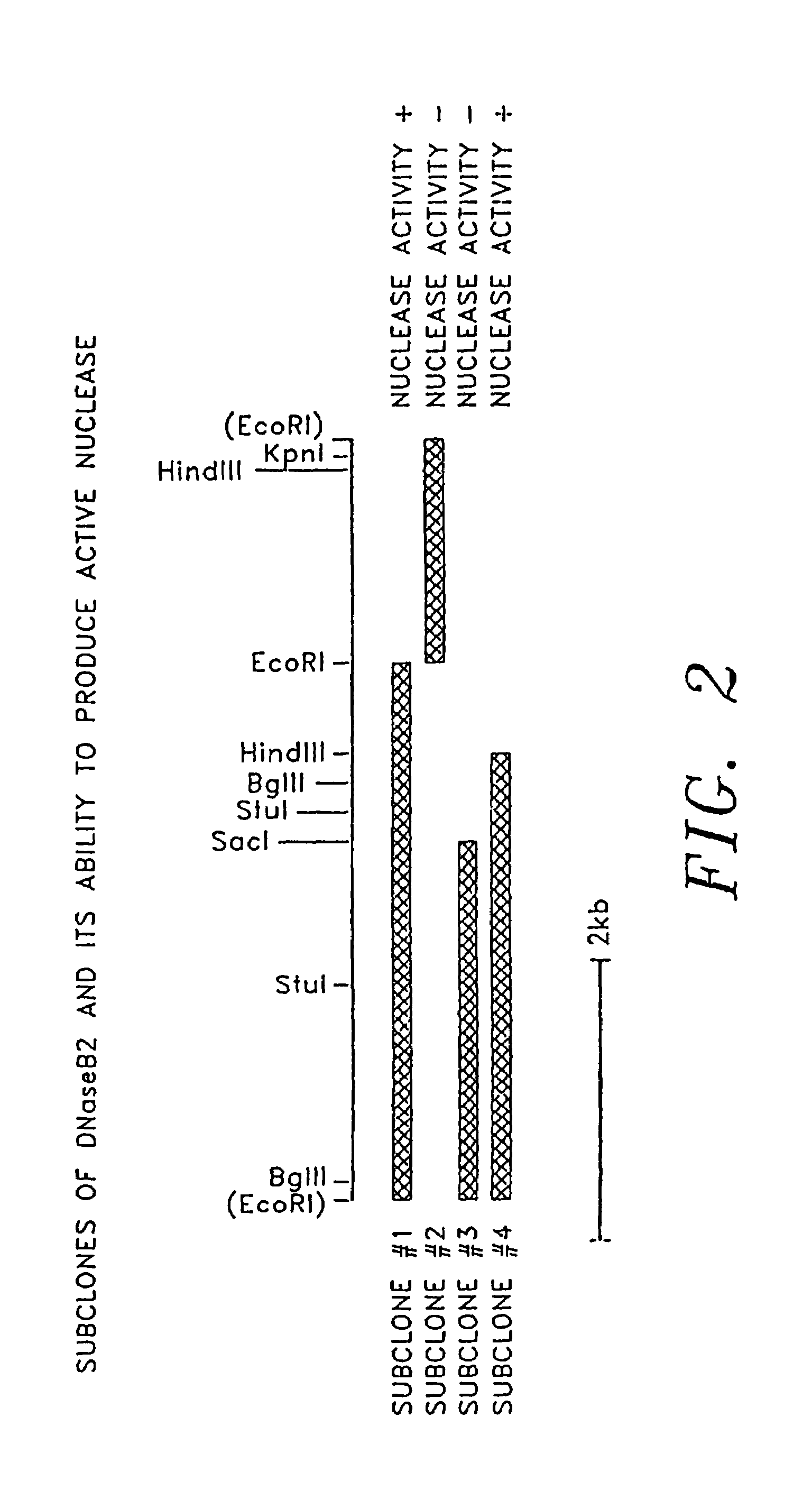

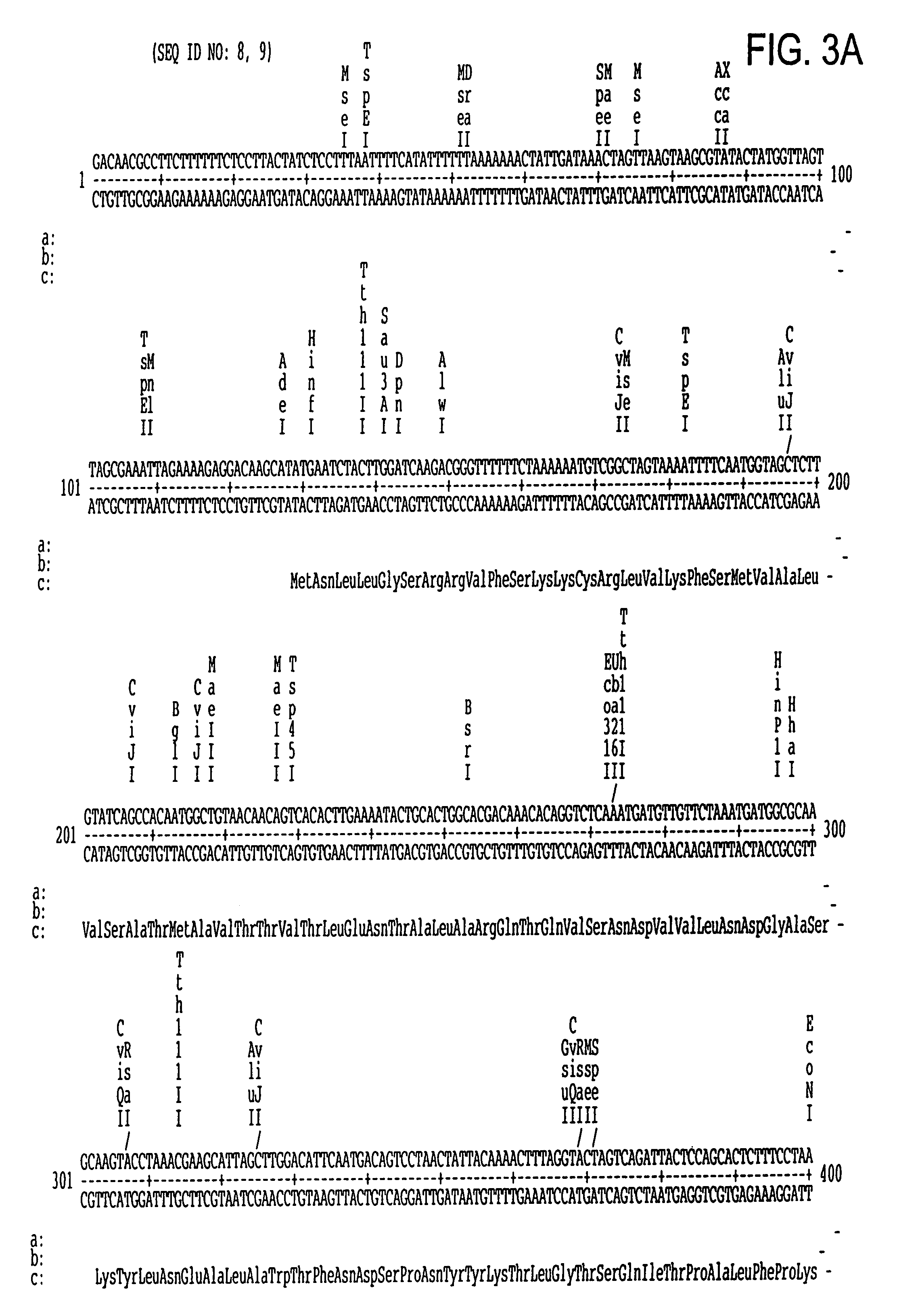

Recombinant DNase B derived from Streptococcus pyogenes

InactiveUS7005510B1Efficient and convenient productionEfficient productionSugar derivativesBacteriaAnti-DNAse B antibodyAntibody

Owner:BECKMAN COULTER INC

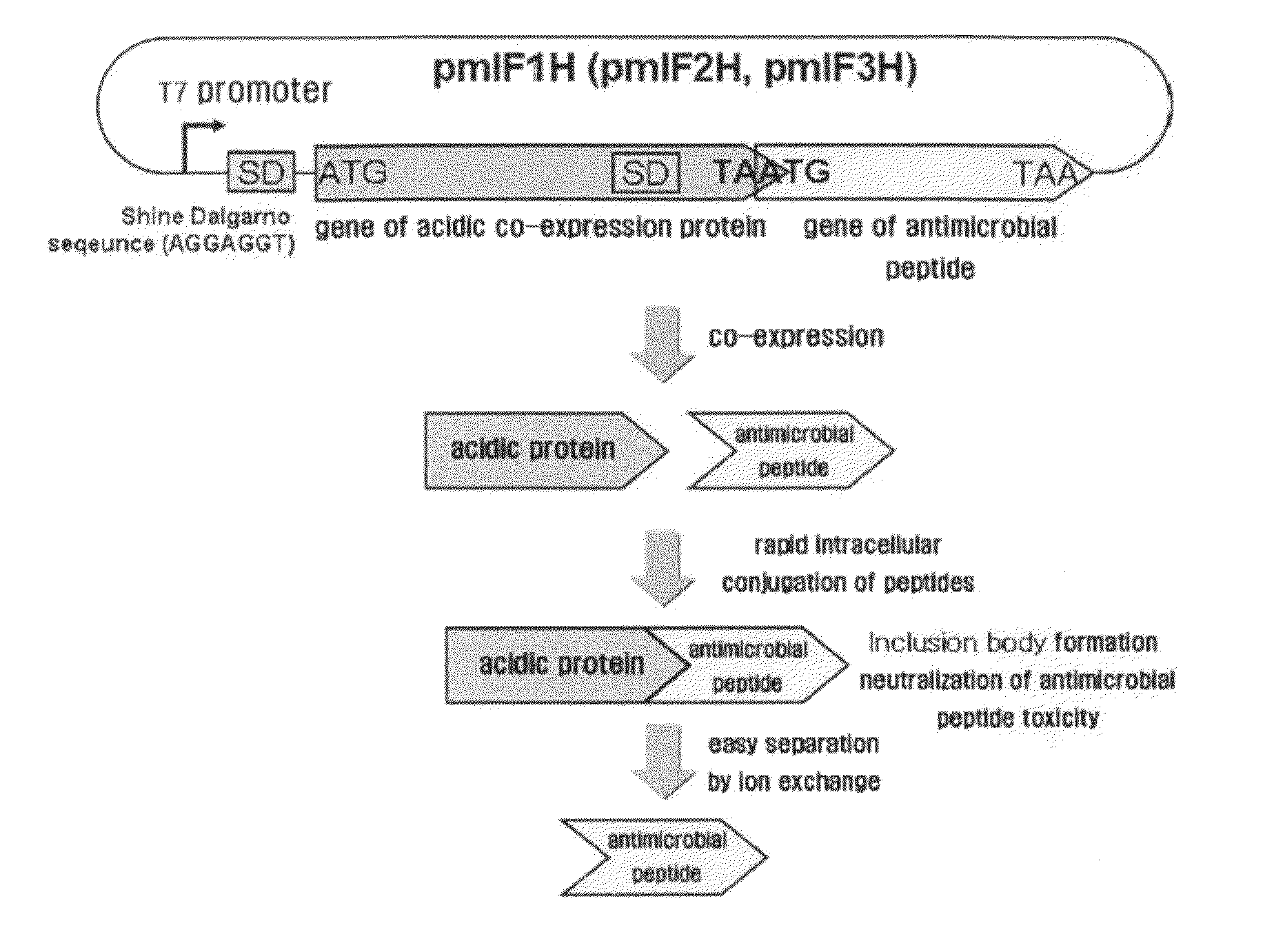

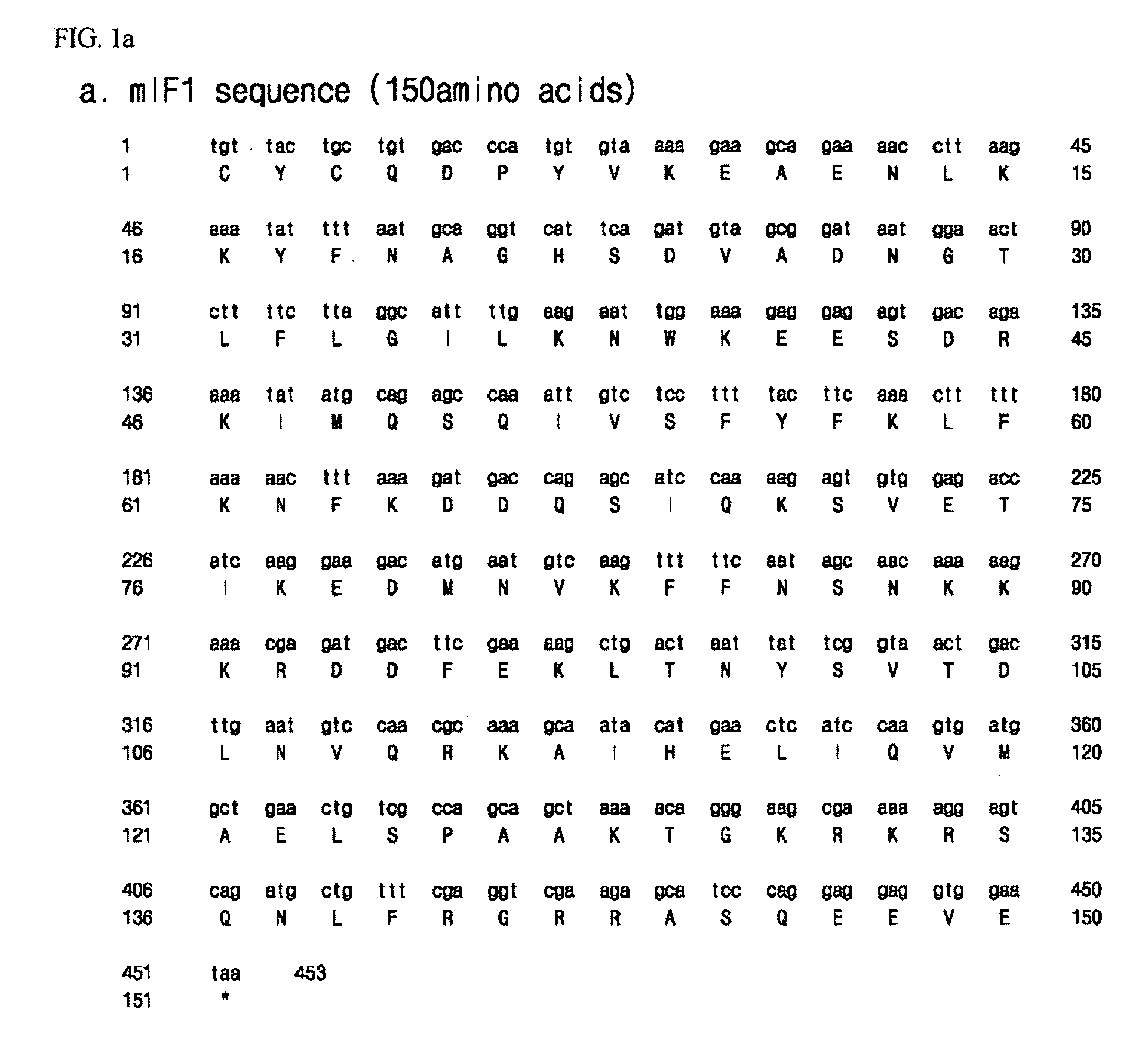

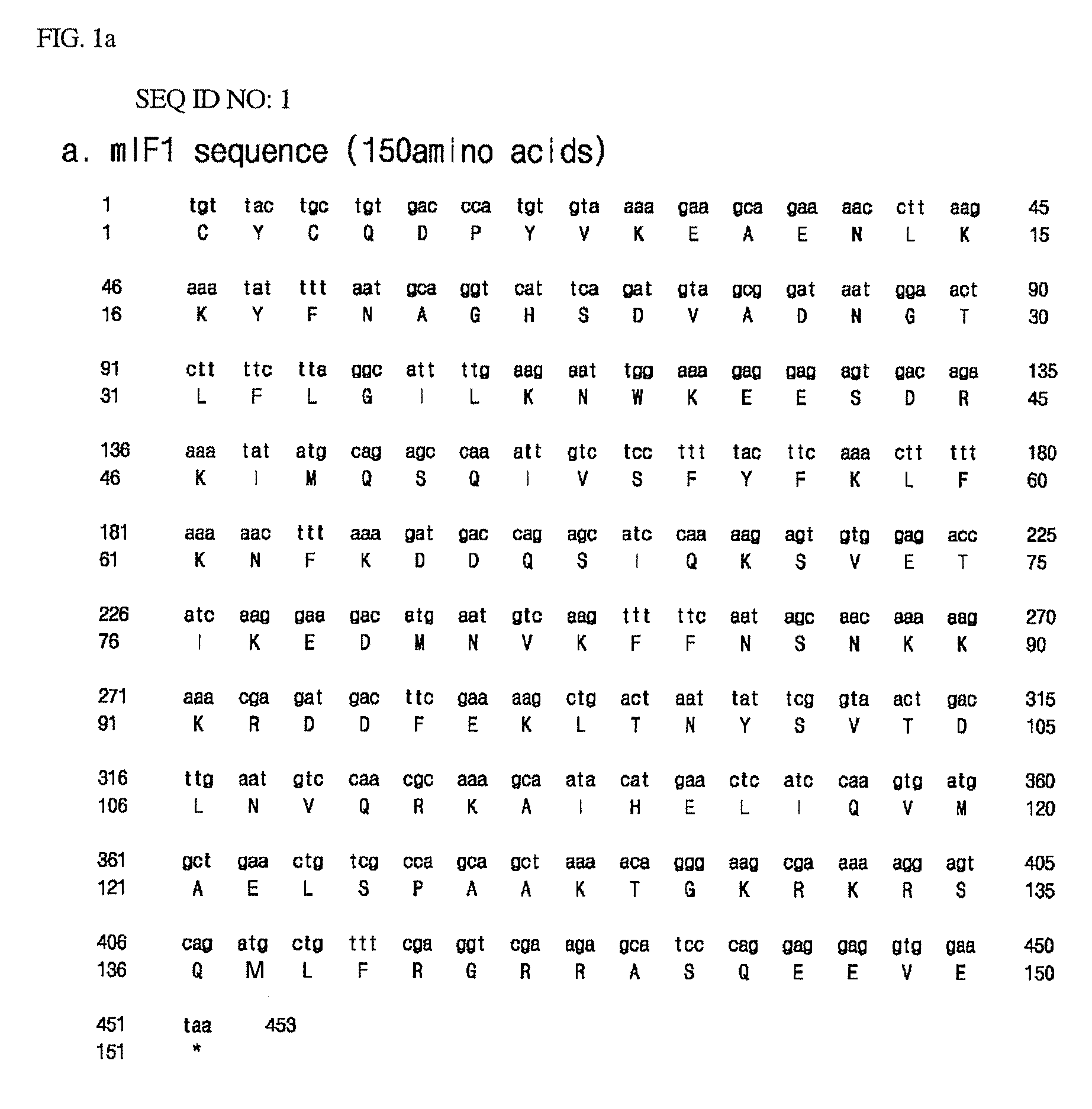

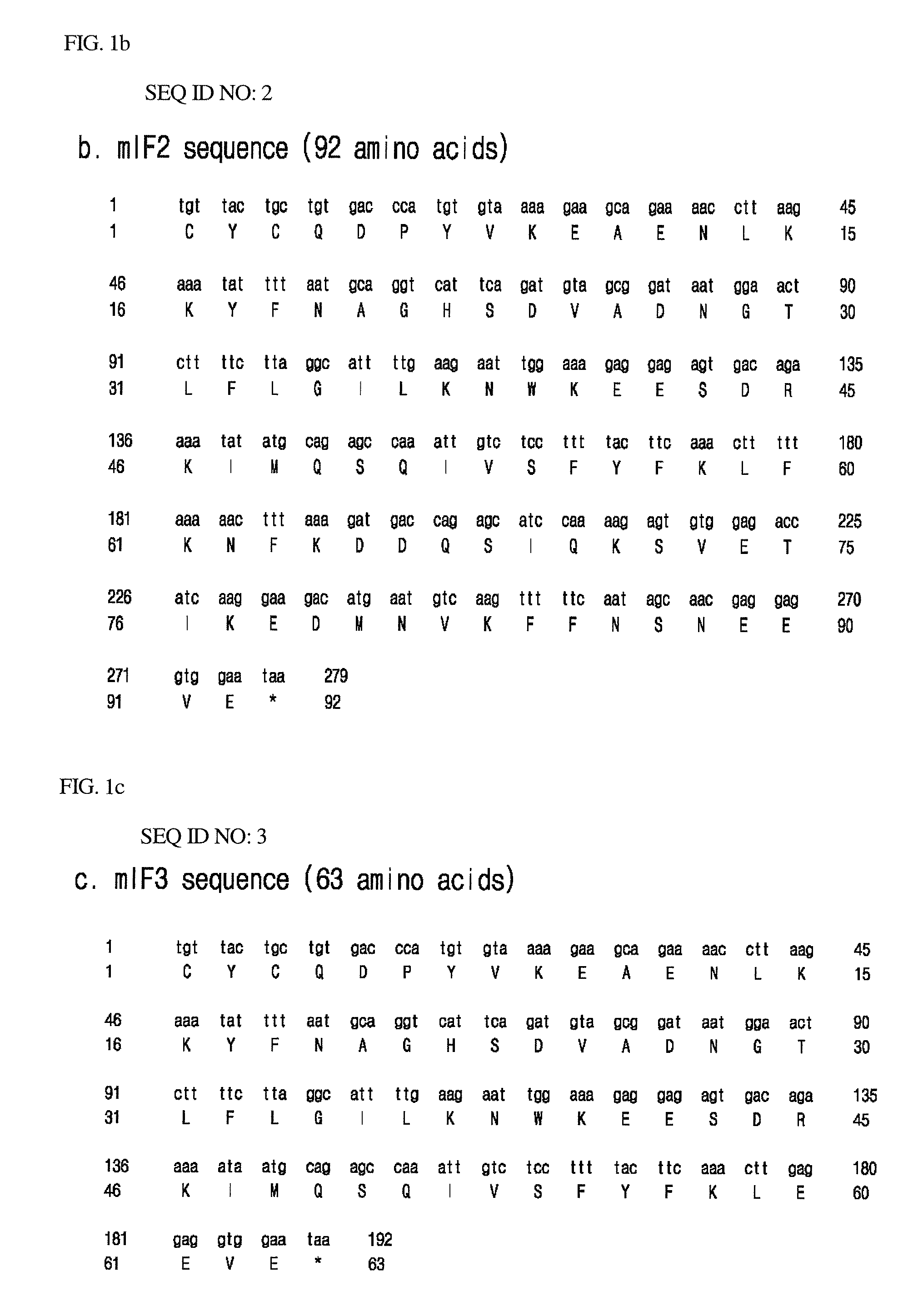

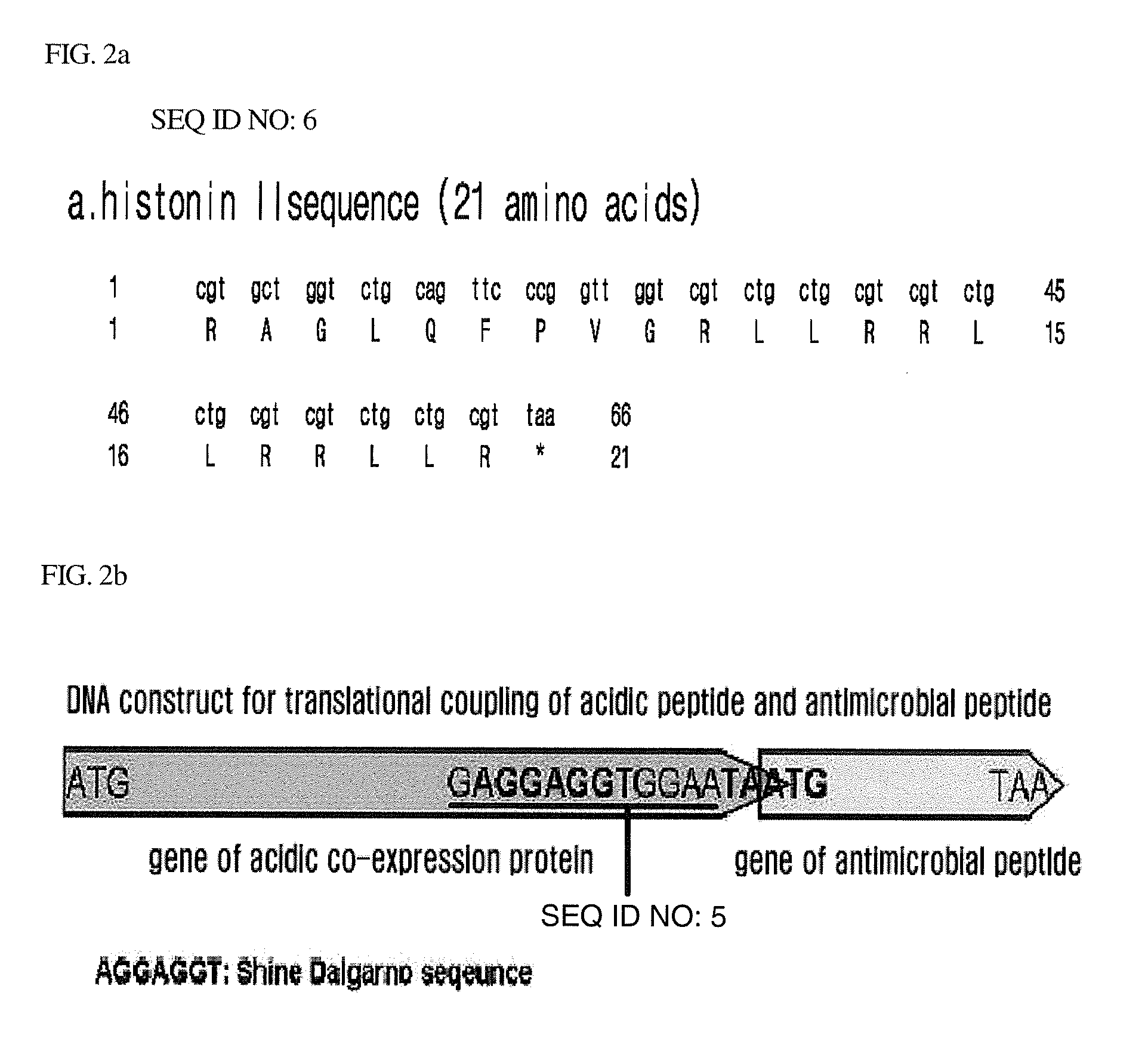

Method for the mass expression of an antimicrobial peptide by using a translational coupling system

ActiveUS20100184949A1Convenient and efficient mass production of antimicrobialLoss of productivitySugar derivativesPeptide/protein ingredientsMicroorganismCytotoxicity

The present invention relates to a gene construct which is capable of achieving efficient production of an antimicrobial peptide in a microorganism, and a method for efficient mass production and separation of an antimicrobial peptide using the same. The gene construct of the present invention has a translationally coupled configuration of two independent and separate cistrons which encode an acidic peptide and a basic antimicrobial peptide, each having an opposite charge, under the control of a single promoter. The translationally coupled acidic peptide and basic antimicrobial peptide undergo charge-charge interaction simultaneously with expression thereof to neutralize the potential cytotoxicity of the antimicrobial peptide, resulting in prevention of antimicrobial peptide-mediated killing of host microorganisms. In addition, a conjugate of the acidic peptide and the antimicrobial peptide can be separated without chemical or enzymatic treatment. Therefore, it is possible to achieve easy mass production of antimicrobial peptides from recombinant microorganisms.

Owner:KOREA ADVANCED INST OF SCI & TECH

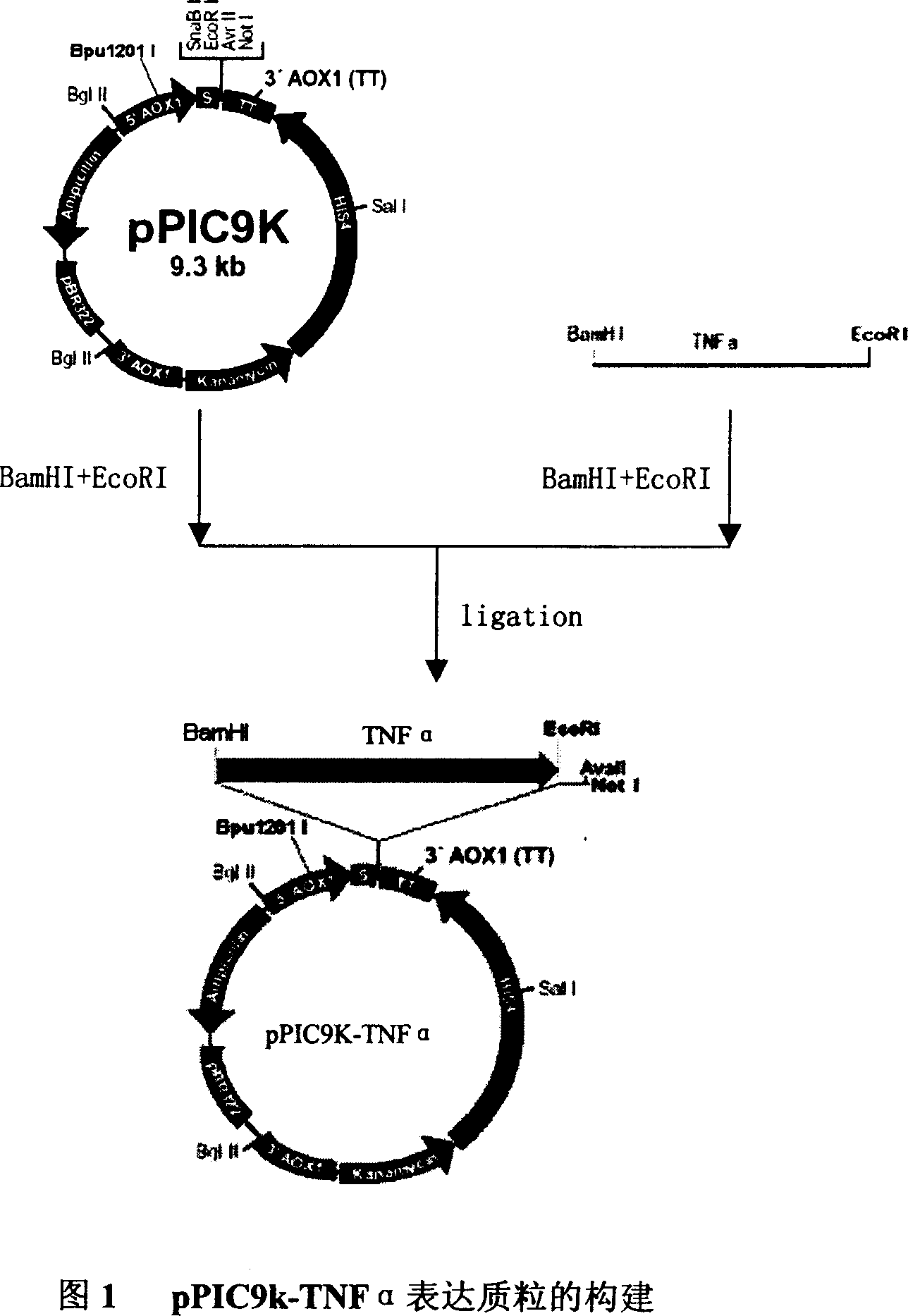

Production method for human tumor necrosis factor TNF-alpha mutant

InactiveCN1876817AEfficient and convenient productionTumor necrosis factorPeptide preparation methodsWilms' tumorMutant

The invention provides a method of producing mutant of tumour necrosis factor called TNF-alphaand the related technology about expression carrying agent and, the construction, expression and decontamination of engineering cell. The protein gene of mutant of tumour necrosis factor called TNF-alpha,which has been optimized, is very much suitable for expression in pichia, meanwhile, improves expression quantity and the rate of purification through the optimization of fermentation and decontamination, has the advantages of high expression, good stability, compact production technology. This invention can get the protein gene of mutant of tumour necrosis factor called TNF-alpha with performance, briefness and low cost.

Owner:SHANGHAI NEWSUMMIT BIOPHARMA

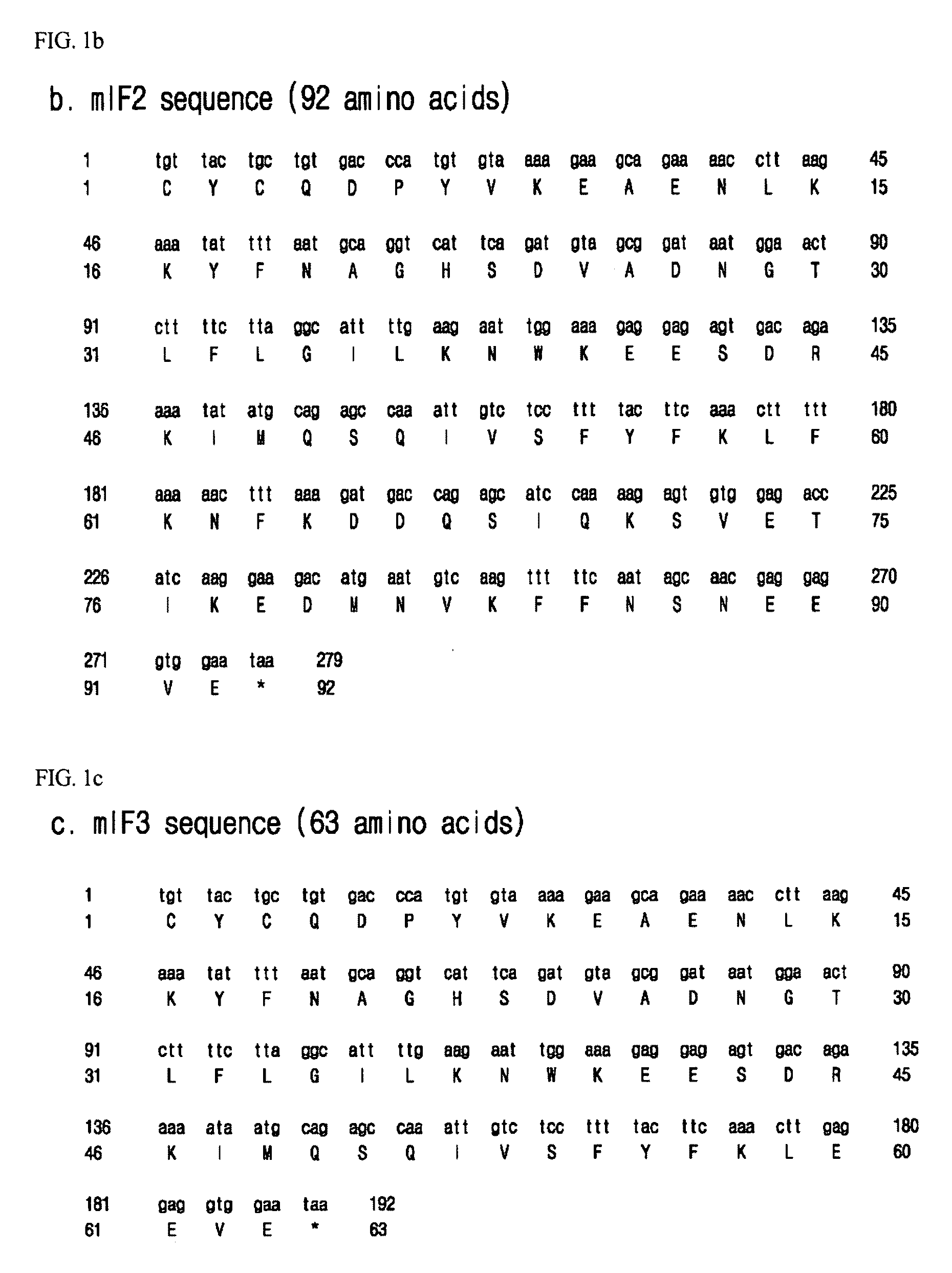

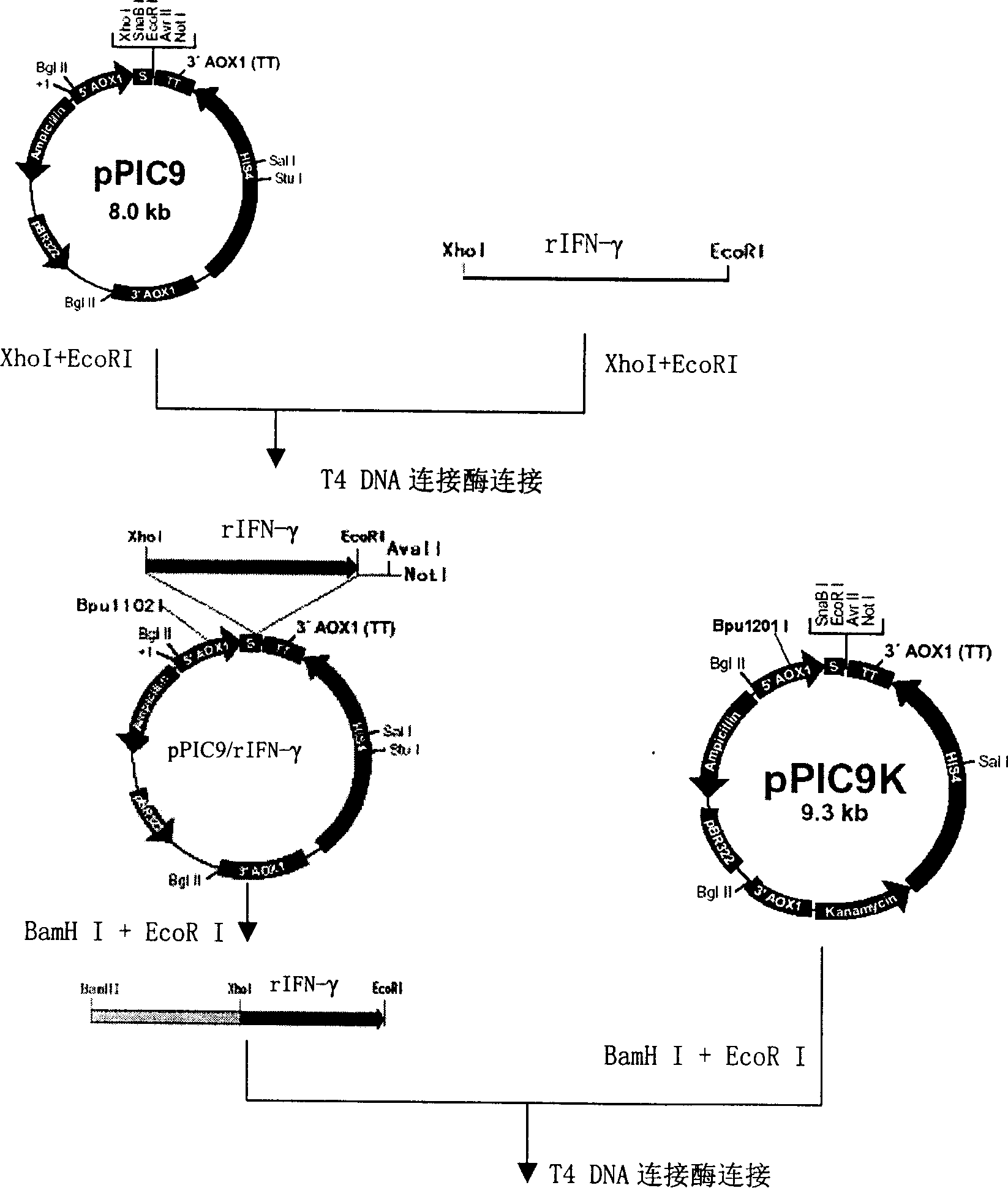

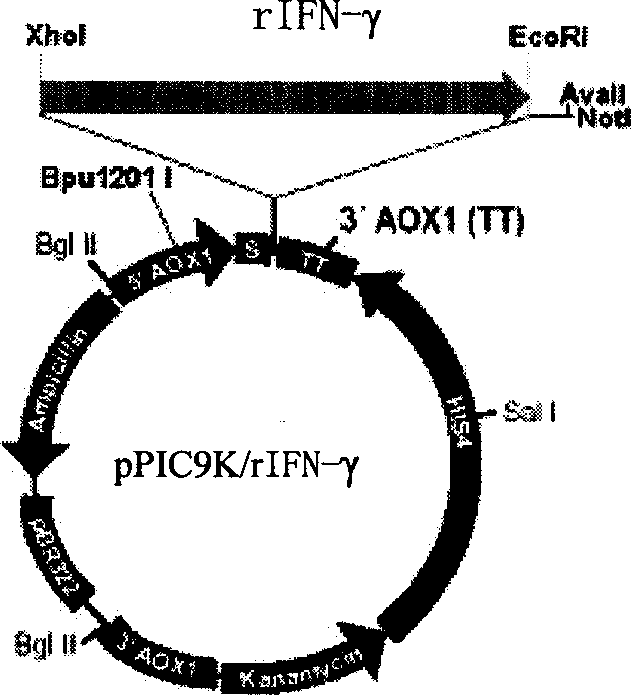

Production method of recombination human interferon gamma

InactiveCN1869228AEfficient and convenient productionFermentationInterferonsNucleotideNucleotide sequencing

The invention relates to a reconstruction interferon gamma nucleotide sequence and the manufacture method to produce reconstruction interferon gamma, and the relative expression carrier and engineer cell construction, expression and purification technology. The method improves the expression quantity and the purification yield. It has the advantage of high expression, good stability, and simple technology. It could gain reconstruction human interferon gamma high efficiently, conveniently and in low cost.

Owner:SHANGHAI NEWSUMMIT BIOPHARMA

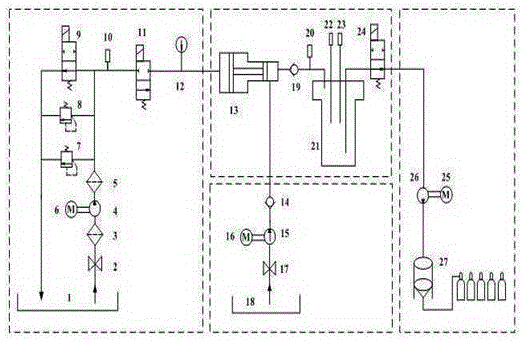

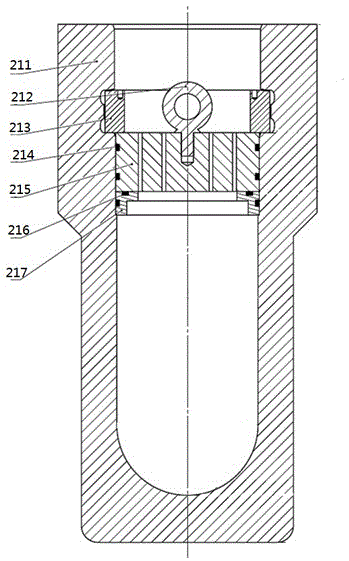

Water-hydraulic ultrahigh pressure system for liquid food and production device thereof

InactiveCN105054214AReasonable designSafe by designServomotorsFood preservationPressure systemLiquid state

The invention discloses a water-hydraulic ultrahigh pressure system for liquid food and a production device thereof, and belongs to the field of liquid food processing. The ultrahigh pressure system comprises a water-hydraulic system, a liquid food delivering, pressurizing, and pressure-maintaining system, and a filling system, which are connected in sequence. The water-hydraulic system provides basic work power to the whole system, the liquid food is subjected to an ultrahigh pressure treatment in the liquid food delivering, pressurizing, and pressure-maintaining system, then the processed liquid food is automatically extracted from the pressure cylinder and filled, the ultrahigh pressure system can prominently improve the processing efficiency of liquid food, and the production process is clean and pollution-free. At the same time, the pressure cylinder used in the processing process has a simple structure, is convenient to operate, and is suitable for the ultrahigh pressure system.

Owner:SOUTH CHINA AGRI UNIV

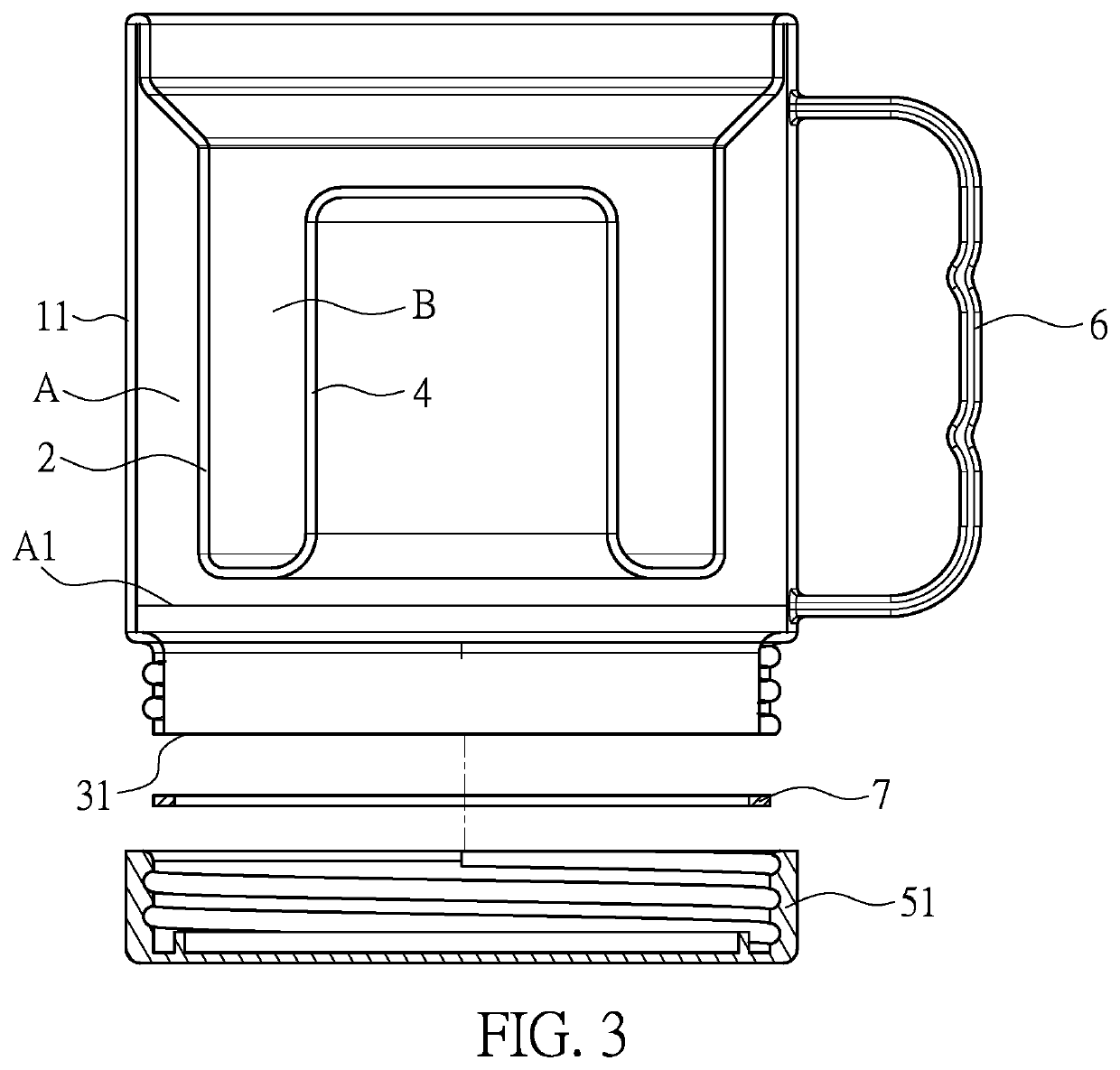

Rapid beverage cooling device and refrigeration method thereof

InactiveUS20220287486A1Simple and reasonable structureRapid coolingLighting and heating apparatusCooling fluid circulationRefrigerationPhysics

A rapid beverage cooling device and a refrigeration method thereof are provided. The rapid beverage cooling device includes an outer cup body and an inner cup body of which rims are connected. An interlayer inner cavity for storing a liquid is formed between the outer cup body and the inner cup body; a liquid injection port communicated with the interlayer inner cavity is made at a bottom of the outer cup body; the liquid injection port can be opened or sealed; a liquid accommodating cavity is disposed in the inner cup body; a convex column extends toward the liquid accommodating cavity from a wall of the inner cup body; and an inner cavity of the convex column is communicated with the interlayer inner cavity.

Owner:LIU XIAOFENG

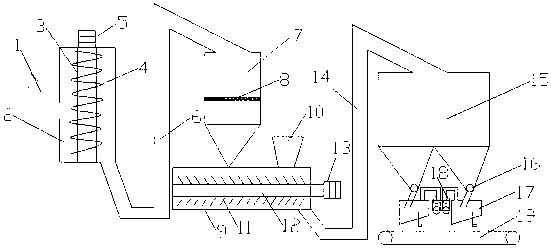

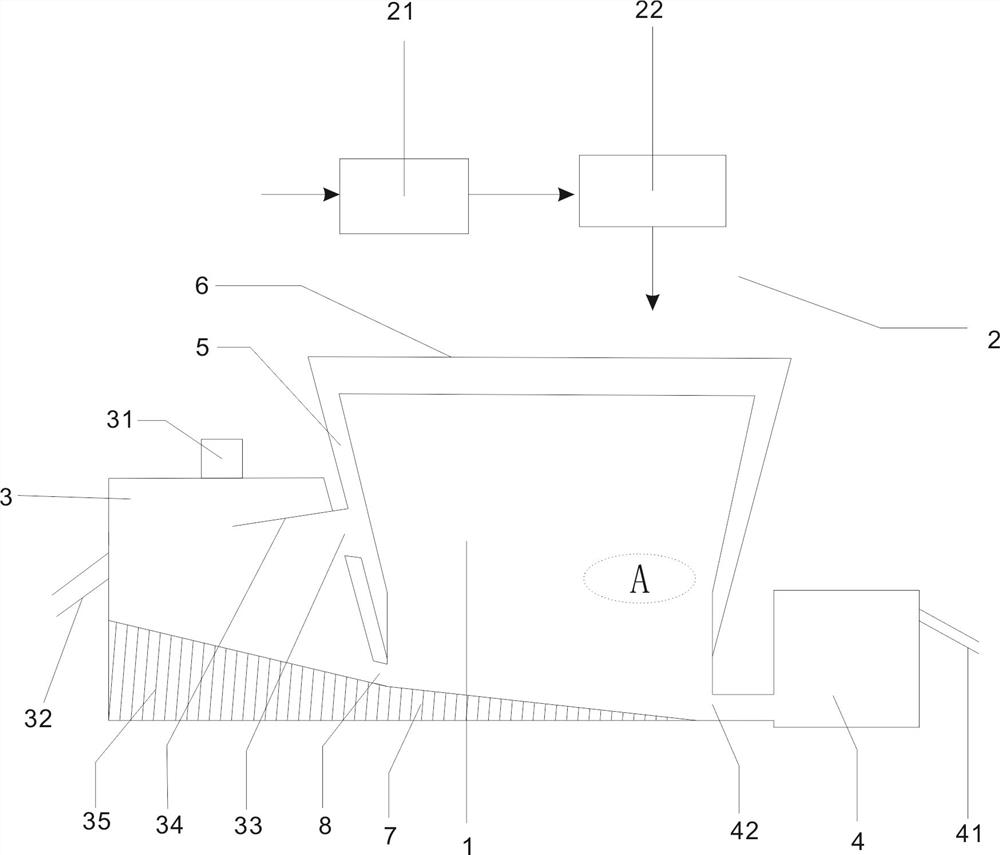

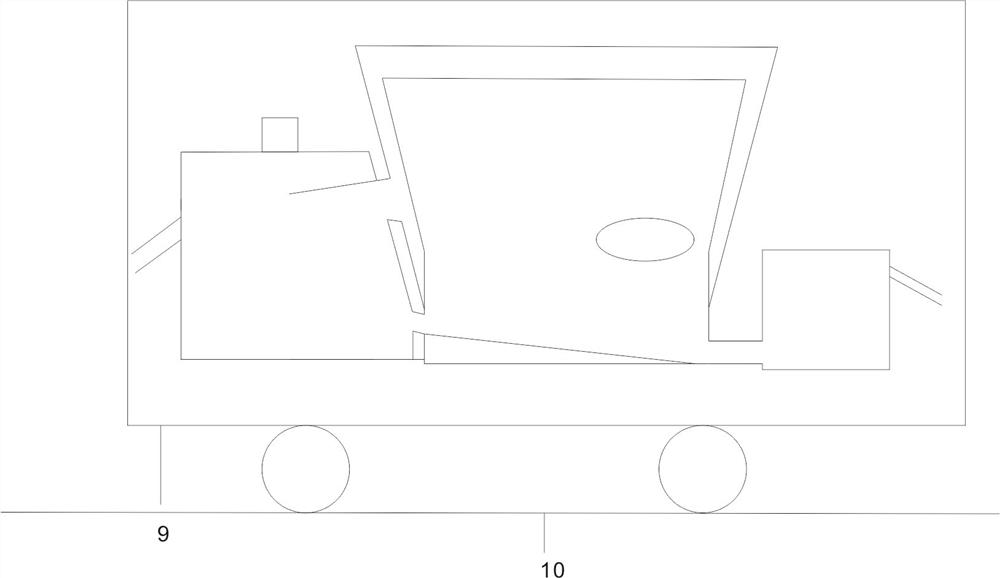

Production system of organic and inorganic compound fertilizer

InactiveCN107721521AReasonable layoutEfficient and convenient productionFertilizer mixturesInorganic compoundCrusher

The invention discloses a production system of organic and inorganic compound fertilizer. The production system comprises a crusher, a quantitative feeding device, a material mixing machine, a fillingmachine and a bag sewing machine, wherein the crusher is provided with an organic fertilizer feeding opening and a discharging opening; the discharging opening is connected with a feeding opening formed in the top of the quantitative feeding device through a first elevator; a discharging opening of the quantitative feeding device is communicated with the material mixing machine; the material mixing machine is provided with a discharging opening and an inorganic fertilizer feeding opening; a discharging opening of the material mixing machine is connected with a feeding opening of the filling machine through a second elevator ; a discharging opening which is used for outputting through a spiral conveyor is formed in the bottom of the filling machine; the discharging opening is connected with the bag sewing machine. The production system of the organic and inorganic compound fertilizer, disclosed by the invention, has the advantages of simple technology, safety and high efficiency, highautomation degree, easiness for controlling and large-scale production; the production efficiency is improved and the labor intensity of workers is also reduced.

Owner:ZHENGZHOU JINGHONG ANIMAL HUSBANDRY TECH CO LTD

Fusion protein containing leucine-rich repetitive sequence, and preparation method and application thereof

InactiveCN104119446AEfficient and convenient productionFermentationHybrid peptidesSequence signalTert-leucine

The invention discloses fusion protein containing a leucine-rich repetitive sequence, and a preparation method and application thereof. Concretely, the invention relates to fusion protein, and the fusion protein possesses the following structure from N terminal to C terminal: A-X-E-Y1-Y2 (formula Ia) or A-Y2-Y1-E-X (formula Ib), wherein A is an optional secretion signal peptide, X is a member rich in leucine repetitive sequence 1-2 (LRRs1-2) of Slit3 protein (neuronal guidance factor 3), E is a restriction enzyme cutting site, Y1 is a first tag peptide member, Y2 is a second tag short peptide member and the second tag short peptide member is His tag member, and '-' represents a peptide bond or a peptide joint for connecting the above members. The fusion protein is beneficial for correct folding of LRR (leucine-rich repeat) and forming active functional polypeptide, and is capable of simply removing two tag members through once resection enzyme cutting, thereby preparing high-purity high-activity LRR sequence.

Owner:李华顺

Method for the mass expression of an antimicrobial peptide by co-expression of a basic antimicrobial peptide and an acidic peptide using a translational coupling system

ActiveUS8003348B2Efficient and convenient productionLoss of productivitySugar derivativesPeptide/protein ingredientsMicroorganismAntimicrobial peptides

The present invention relates to a gene construct which is capable of achieving efficient production of an antimicrobial peptide in a microorganism, and a method for efficient mass production and separation of an antimicrobial peptide using the same. The gene construct of the present invention has a translationally coupled configuration of two independent and separate cistrons which encode an acidic peptide and a basic antimicrobial peptide, each having an opposite charge, under the control of a single promoter. The translationally coupled acidic peptide and basic antimicrobial peptide undergo charge-charge interaction simultaneously with expression thereof to neutralize the potential cytotoxicity of the antimicrobial peptide, resulting in prevention of antimicrobial peptide-mediated killing of host microorganisms. In addition, a conjugate of the acidic peptide and the antimicrobial peptide can be separated without chemical or enzymatic treatment. Therefore, it is possible to achieve easy mass production of antimicrobial peptides from recombinant microorganisms.

Owner:KOREA ADVANCED INST OF SCI & TECH

Construction and Application of a three-line breeding system in the Peruvian scallop x Bay scallop hybrids

ActiveUS20170245478A1Low costLarge scaleClimate change adaptationPisciculture and aquariaSelf-FertilizationBiology

The current invent relates to the construction and application of a three-line breeding system in the Peruvian scallop×bay scallop hybrids. The said three-line consists of a male sterile line, a maintainer line and a restorer line of the bay scallop×Peruvian scallop hybrids. Herein the Peruvian scallop×bay scallop hybrids are hybrids resulted from the eggs of the Peruvian scallops fertilized with sperm of the bay scallops. In constructing the three-line, male sterile individuals are selected from F1 inter-specific hybrid families and continuously backcrossed with sperm of the selling family of the sperm-providing bay scallops of the F1 hybrid to obtain a combination of male sterile line and maintainer line whose hybrid progenies are all male sterile. Then selected individuals from the male sterile line are continuously backcrossed with sperm from the selfing family of a bay scallop until the resulted progenies are all hermaphroditic and exhibit excellent production traits. Commercial male sterile brood stocks are produced by backcrossing the eggs of the male sterile line with the sperm of the maintainer line and commercial Peruvian scallop×bay scallop hybrid spats are produced by backcrossing the eggs of the male sterile line and sperm of the restorer line. This invent establishes the three-line breeding system in animals for the first time and efficiently overcomes the barrier of self-fertilization in the hybridization between hermaphroditic scallops. The yield of the hybrid scallops can be increased by over 50% compared with the bay scallops.

Owner:QINGDAO AGRI UNIV +1

Niobium-iron alloy continuous production device and production method

ActiveCN111780558ARealize continuous productionRealize cleaner productionMaintainance of heating chambersCharge manipulationSlagNiobium

The invention provides a niobium-iron alloy continuous production device and a production method. The device comprises a smelting furnace, a slag pool and an alloy molten pool; and an alloy generatedin the smelting furnace is molten through siphon separation to discharge from the alloy molten pool, and waste slag is discharged from the slag pool. The device can realize continuous production of aniobium-iron alloy, is higher in heat utilization efficiency in the process, improves the utilization rate of waste heat by above 20%, can further reduce the use level of a smelting furnace material heating agent, realizes clean production of the iron alloy, is low in comprehensive energy consumption, is prominent in energy saving and consumption reducing effects, greatly reduces the production cost, in particular, can realize the reduction operation of production procedures through application of a thermal molten alloy granulation breakage-free process, greatly reduces the slag-rich generation ratio compared with an intermittent production process, improves the procedure metal yield by 2% or above, is excellent in comprehensive economic benefit, improves the production efficiency by above30% compared with a traditional process, is convenient and efficient in production, is environment-friendly, is obvious in technical progress and innovation demonstration effect, improves the productquality, and is prominent in social and economic benefits.

Owner:CHINA MOLYBDENUM

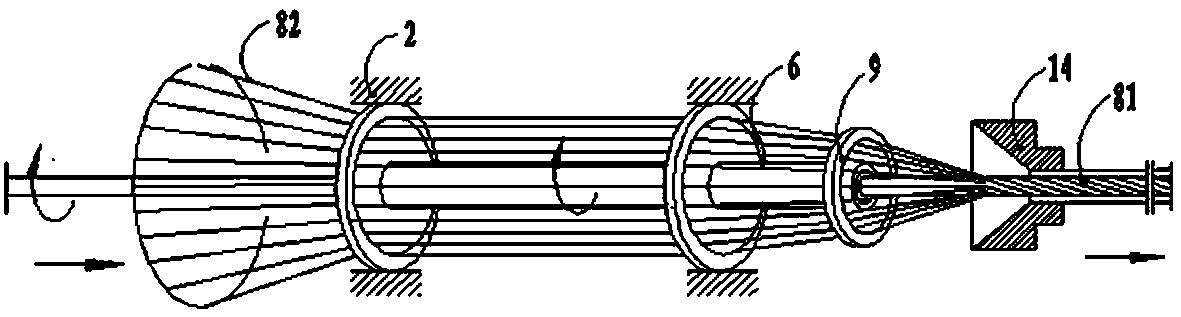

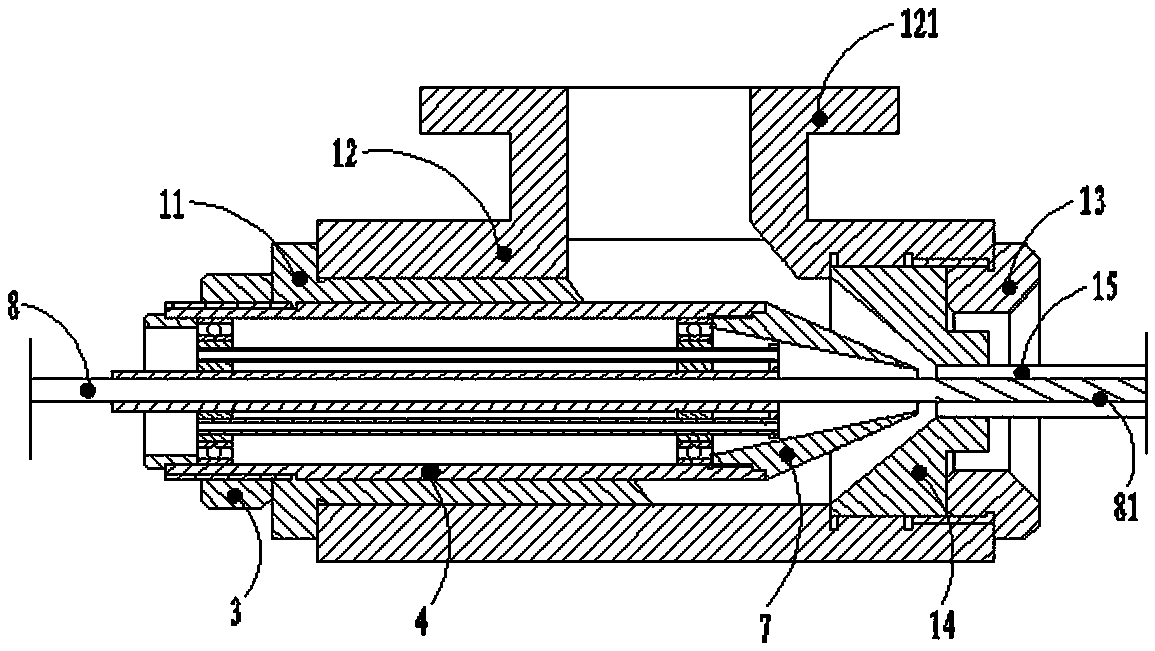

Extrusion mold for electric cable

InactiveCN103341960BSolve the problem of poor uniformity of the gap distribution of the wrapped single wireReduce manufacturing costElectrical conductorEngineering

The invention relates to the electric wire and electric cable manufacture field, and particularly to a plastic extruding mould required by production of a concentric sparse winding shielding layer of a plurality of single-wire conductors under a cable sheath layer. Disclosed is the plastic extruding mould for producing electric cables. The plastic extruding mould includes a plastic extruding mould base; a male mould and a female mould are respectively arranged at two sides of a cavity in the plastic extruding mould base, a mould cavity is formed between the male mould and the female mould, the female mould is connected with a forming pipe, and the male mould is connected with a mould body; the interior of the mould body is connected with a stranding cage through bearings, the interior of the stranding cage is provided with a threading pipe, the stranding cage can rotate around the threading pipe, the right end of the stranding cage is provided with a distributing terminal board, and the distributing terminal board is provided with wire harness conduits. A wire core is passed through the threading pipe, then through the male mould and the female mould, next through the forming pipe, and is connected with a traction machine set; and sparse winding single wires are passed through the wire harness conduits and the distributing terminal board.

Owner:SICHUAN JIUZHOU WIRE & CABLE

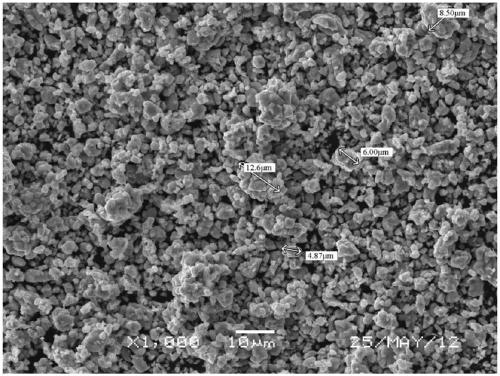

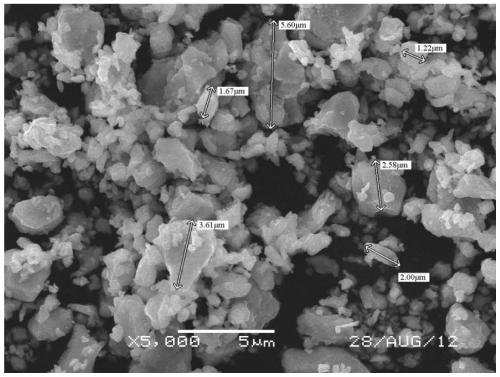

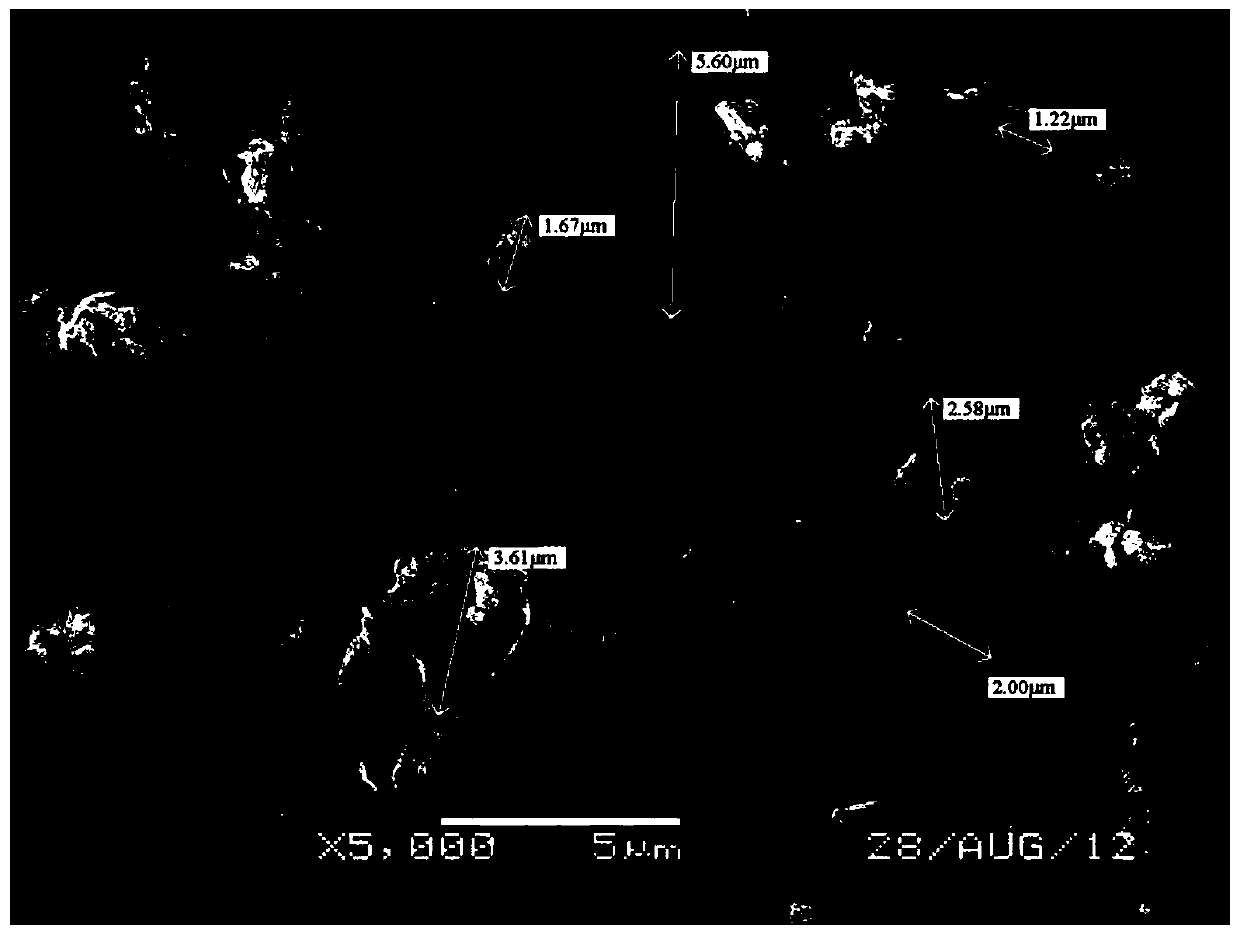

A kind of cuprous oxide powder and preparation method thereof

ActiveCN107162038BThe preparation method is simple and easyConcentration of particle sizeCopper oxides/halidesMolten stateNitrogen

The invention discloses cuprous oxide powder and a preparation method thereof. The preparation method of the cuprous oxide powder is as follows: smelting pure copper to a molten state, directly atomizing the copper in the molten state in a nitrogen and oxygen mixed atmosphere for oxidation reaction of the copper and oxygen to obtain the cuprous oxide powder. During production of the cuprous oxide powder by the atomization method, the nitrogen and oxygen mixed atmosphere is introduced for high-temperature oxidation of the pure copper and the oxygen in the atomization process to prepare the cuprous oxide powder, meanwhile because of lack of oxygen, cuprous oxide cannot continue to react with the oxygen to form copper oxide. The preparation steps of the method are efficient, fast and convenient, production steps are saved, the production method of the cuprous oxide powder is broadened; and the cuprous oxide powder prepared by the preparation method has relatively concentrated and uniform particle size distribution and excellent physical properties, and is easy to use later.

Owner:苏州昆腾威新材料科技有限公司

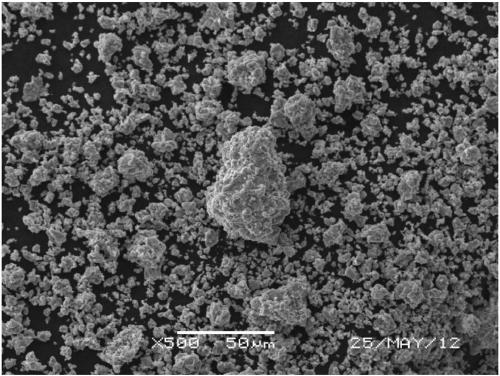

Piston type bean sprouting machine

InactiveCN104067925AEfficient and convenient productionAgriculture gas emission reductionCultivating equipmentsEngineeringLED lamp

The invention provides a piston type bean sprouting machine. The piston type bean sprouting machine comprises a frame (1); a cylindrical structure (2) is arranged in the frame; the cylindrical structure (2) is provided with a supporting plate (3); a water catchment basket (4) is arranged under the supporting plate; bean materials are put on the supporting plate; a piston type bearing plate (5) is arranged above the bean material region; in use, the piston type bearing plate (5) is raised in a piston manner by the lifting force generated by the sprouting of the bean materials, and therefore, the production quality of the bean sprout is improved; water catchment holes are formed in the supporting plate (3) and the root system of the bean sprout absorbs moisture from the water catchment basket; a sensor (6) is arranged on the upper portion of the cylindrical structure (2) and used for detecting the production status of the bean sprout and immediately sending out prompt information by use of voice or LED (Light-Emitting Diode) lighting; as the production status of the bean sprout can be detected and the prompt information can be sent out immediately, the yield can be increased.

Owner:ANQING LINGKANG ELECTROMECHANICAL PROD DESIGN

Sanitary towel partner trousers

The invention discloses sanitary towel partner trousers which comprise a trousers body composed of a single elastic inner core non-woven fabric, and the elastic inner core non-woven fabric is formed by compounding two non-woven fabric layers, a plurality of elastic fibers clamped between the two non-woven fabric layers and a plurality of point-shaped connecting lines perpendicular to the elastic fibers. A circle of elastic waistline is arranged at the top end of the trouser body along the trend of the elastic fibers, thigh openings are arranged on two sides of the trouser body, and pressing edges are arranged on the two sides of the trouser body and the edges of the thigh openings. The sanitary towel is made of the single elastic non-woven fabric, the elasticity and the air permeability are both considered, the good comfort degree is provided, the strength and the durability are good, the sanitary towel can be conveniently placed, the sanitary towel can be better attached to the private position of a woman, the overall structure is simple, replacement is easy, the production cost is low, and therefore the sanitary towel is easy to popularize and convenient to use.

Owner:广东强的卫材科技有限公司

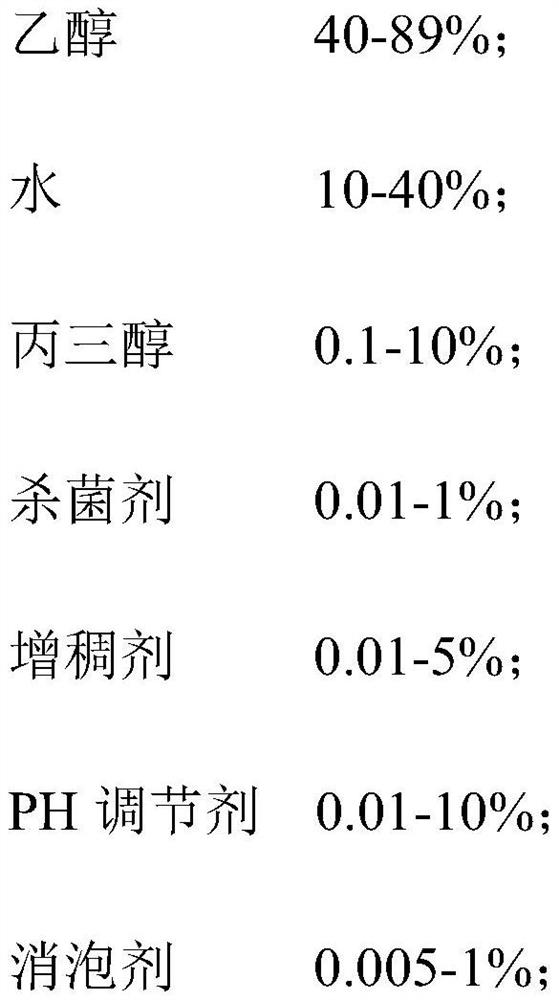

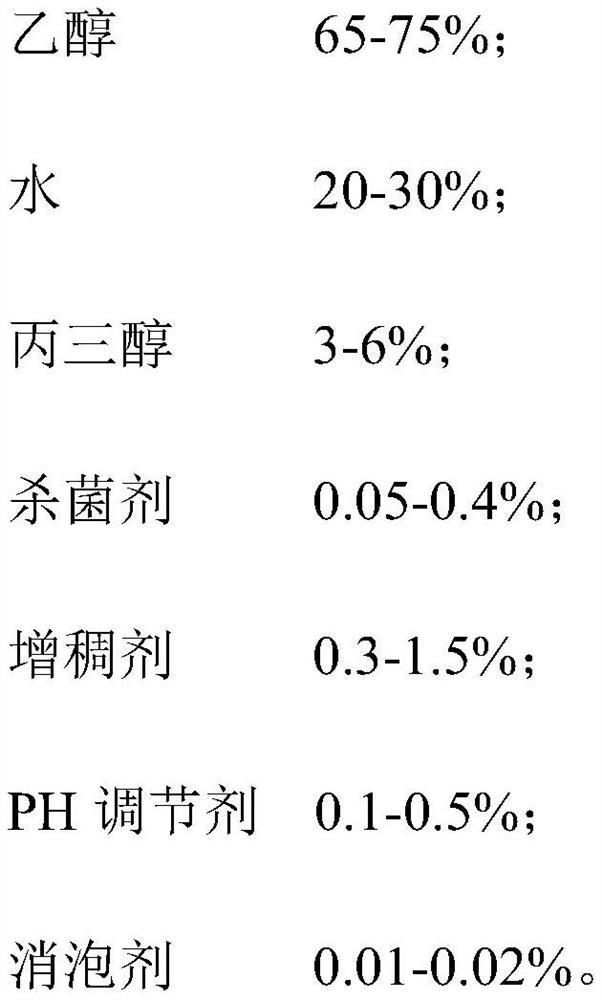

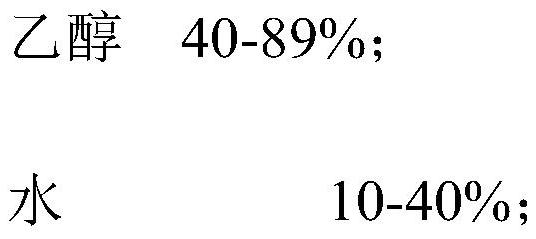

Convenient and easy-to-produce hand-washing-free disinfection gel and preparation method thereof

PendingCN113288860AEfficient and convenient productionShorten the production cycleHydroxy compound active ingredientsAerosol deliveryCelluloseGlycerol

The invention discloses hand-washing-free disinfection gel convenient and easy to produce and a preparation method of the hand-washing-free disinfection gel, and relates to the field of disinfectant preparation. The hand-washing-free disinfection gel comprises the following components in percentage by weight: 40-89% of ethanol; 10-40% of water; 0.1-10% of glycerol; 0.01-1% of a bactericide; 0.01-5% of a thickening agent; 0.01-10% of a pH regulator; 0.005-1% of a defoaming agent; wherein the thickening agent is a cationic cellulose thickening agent. According to the hand-washing-free disinfection gel, the cationic cellulose thickening agent and the defoaming agent are added, so that the defects of long production period and complex production process caused by long dissolving time of the thickening agent during production of a traditional hand-washing-free disinfection gel product and standing after production are avoided, and efficient and convenient production of the hand-washing-free disinfection gel is realized. As cations in the cationic cellulose thickening agent are uniformly distributed on a main chain of a polymer, the cationic cellulose thickening agent has higher viscosity when being independently dispersed in a water phase, and the production period of producing a hand washing gel product can be greatly shortened.

Owner:JIANGXI CHEPU IND CO LTD

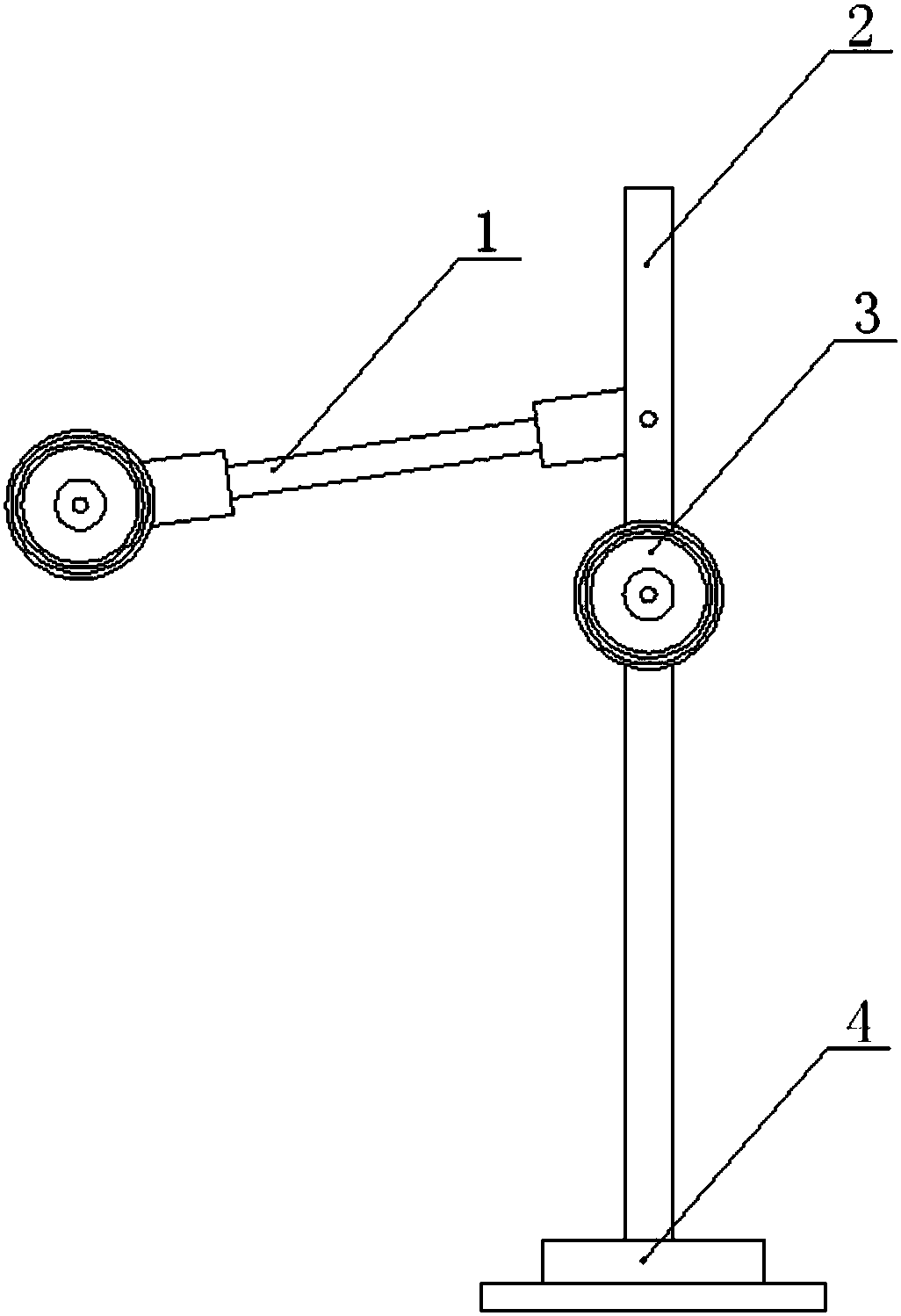

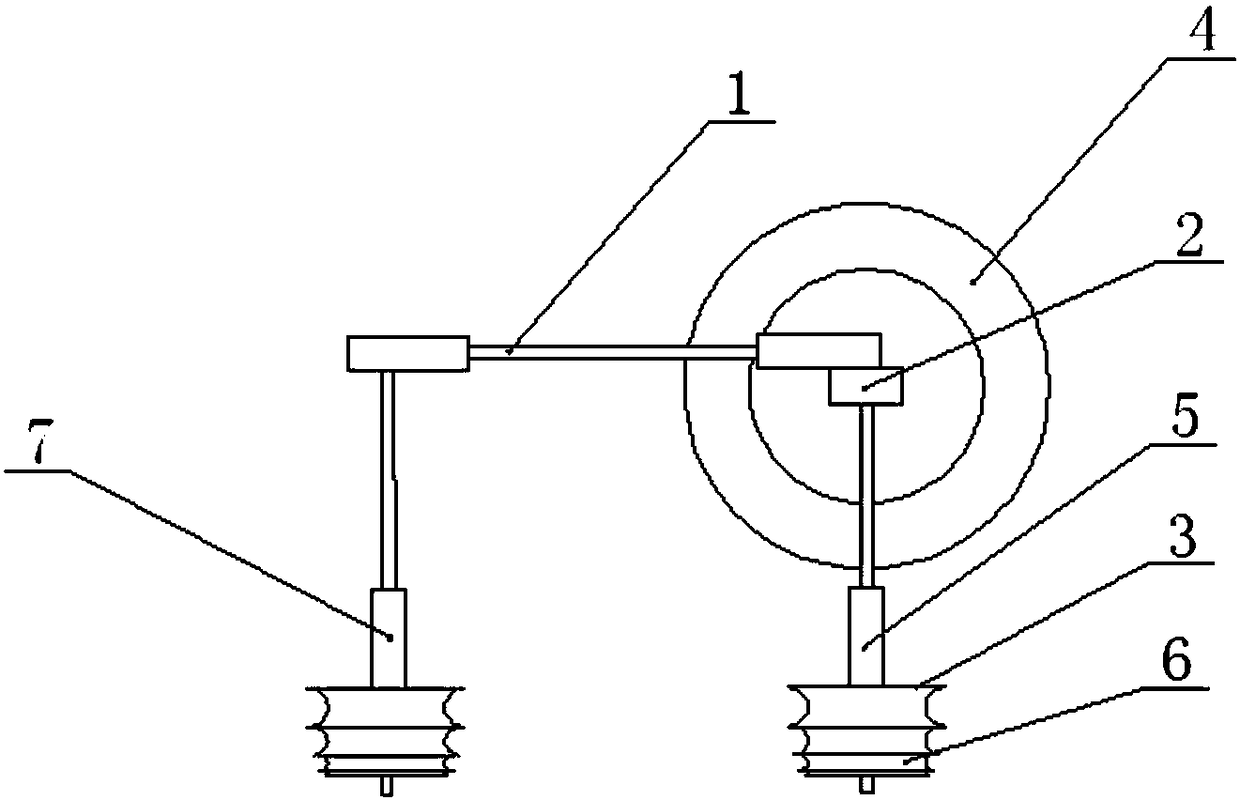

A fiber guide device suitable for secondary plastic coating process

The invention relates to an optical fiber guiding device suitable for a secondary plastic coating technology. The optical fiber guiding device consists of a floor stand, telescopic rods and guide pulley groups, wherein an upper horizontal telescopic rod and a second telescopic rod are hinged to the floor stand; a first telescopic rod is connected to the front end of the upper horizontal telescopic rod; the two guide pulley groups are respectively mounted at the front end of the first telescopic rod and the front end of the second telescopic rod. The optical fiber guiding device disclosed by the invention is simple in structure and reasonable in design; the telescopic rods and the guide pulley groups are arranged, so that optical fibers in different specifications are guided; the optical fiber guiding device has multiple purposes, is convenient and efficient; the problems that in the prior art, in the mass production process, the guiding of the optical fibers in various specifications is not liable to control, and the work is many and diverse, time-consuming and labor-consuming are solved; the accurate control of the remained length of bundled pipes is facilitated, so that the production is efficient and convenient, and the optical fiber guiding device disclosed by the invention is suitable for wide popularization and application.

Owner:天津立孚光电科技股份有限公司

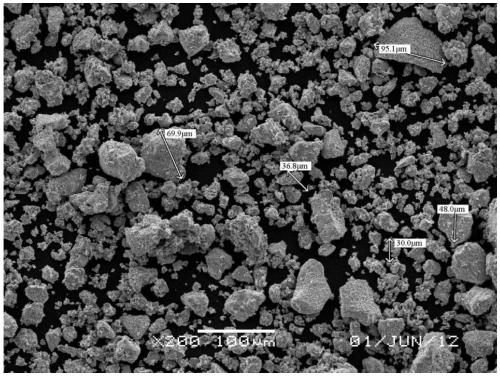

A kind of copper oxide powder and preparation method thereof

ActiveCN107311220BSimple production methodConcentration of particle sizeCopper oxides/halidesMolten stateCopper oxide

The invention discloses copper oxide powder and a preparation method thereof. The preparation method of the copper oxide powder comprises the following steps: smelting pure copper into a molten state, directly performing atomization treatment on the copper in the molten state in an oxygen atmosphere, enabling the copper and oxygen to generate sufficient oxidation reaction and obtaining the copper oxide powder. The preparation method of the copper oxide powder, provided by the invention, has the advantages that when the copper oxide powder is prepared by utilizing an atomization method, the pure oxygen is introduced, so that the copper and the oxygen are oxidized at a high temperature in the atomizing process to prepare the copper oxide powder, therefore, the production step is saved, and the production method of the copper oxide powder is widened; the obtained copper oxide powder is relatively concentrated in particle size, uniform in distribution and excellent in performance.

Owner:苏州昆腾威新材料科技有限公司

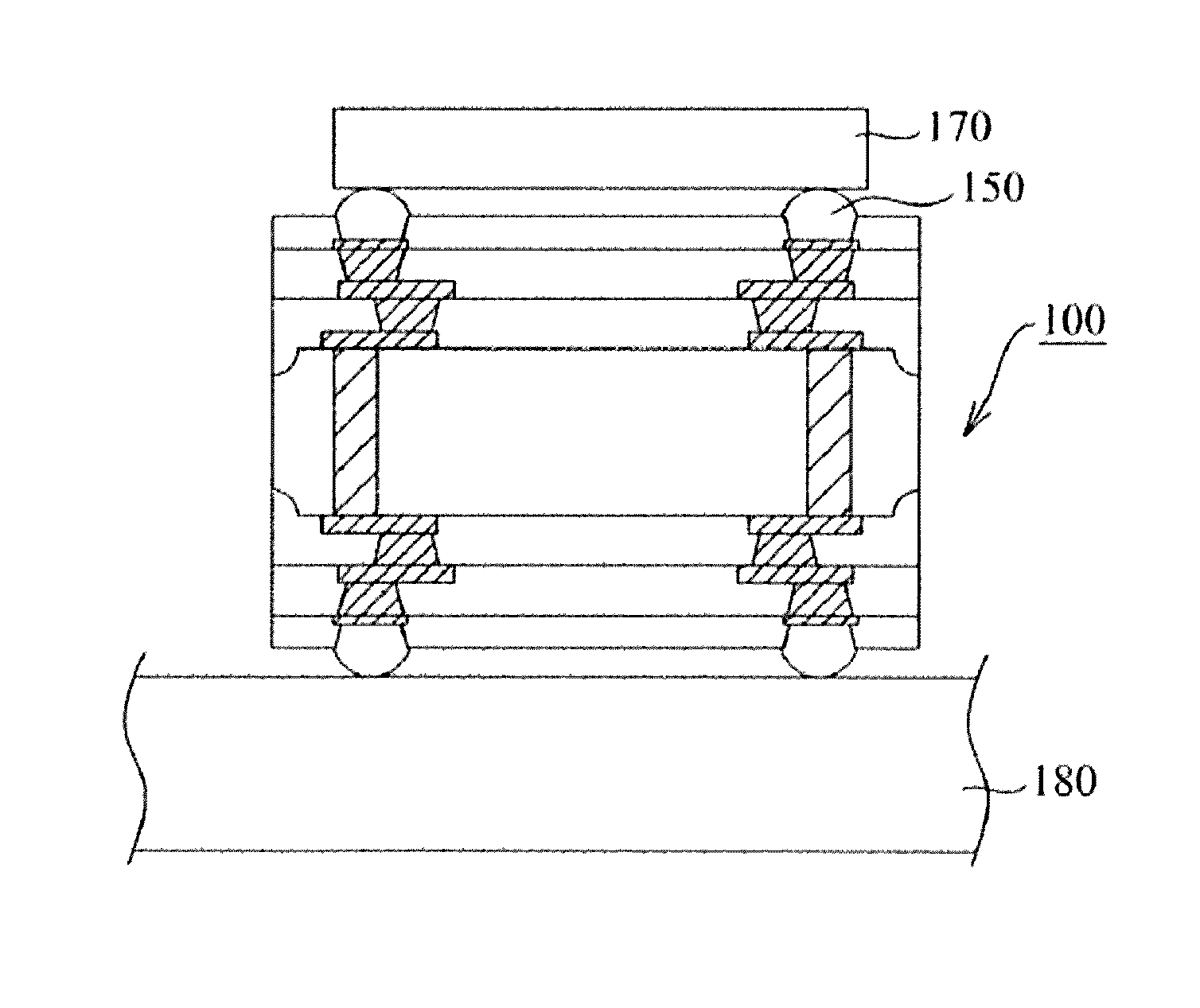

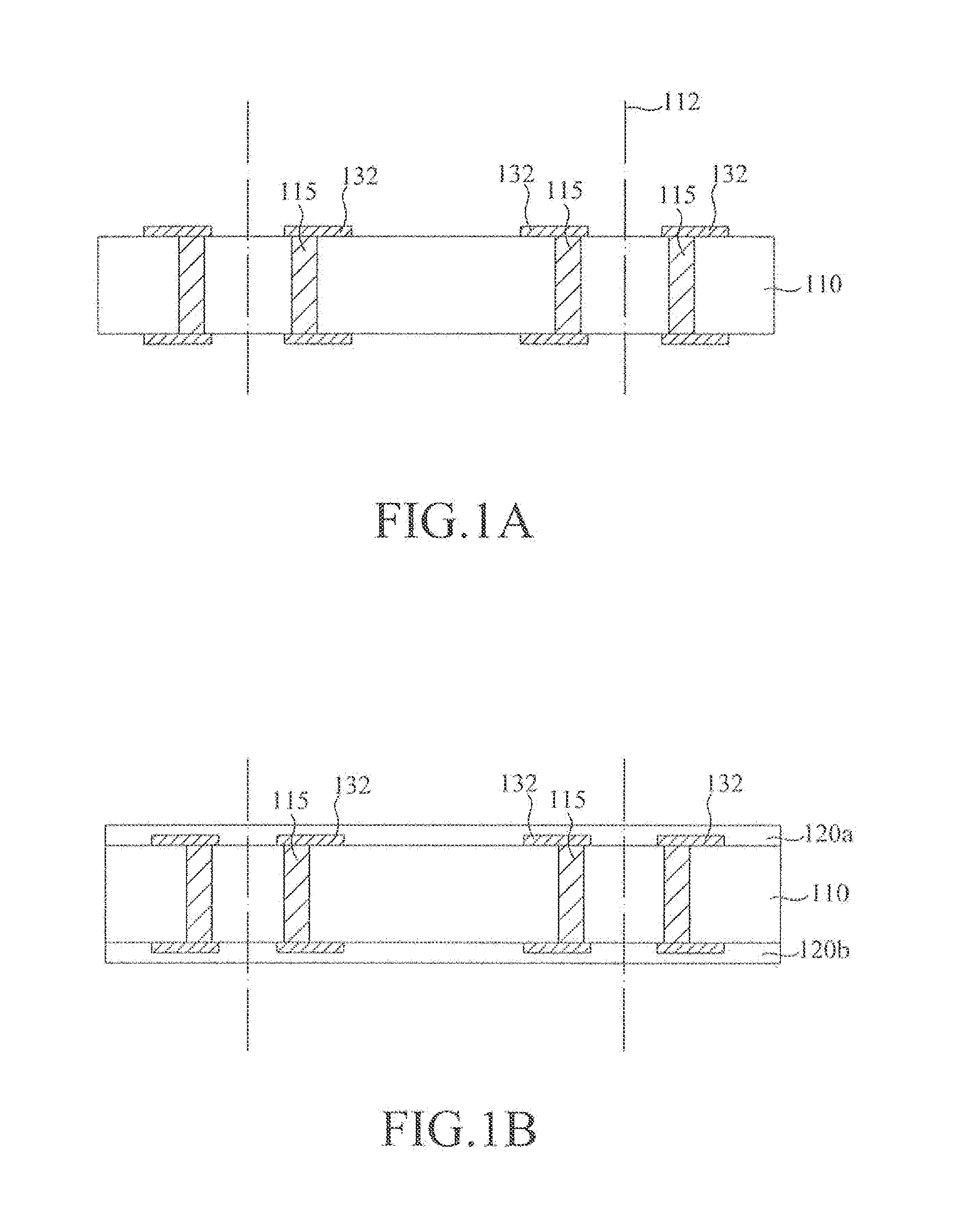

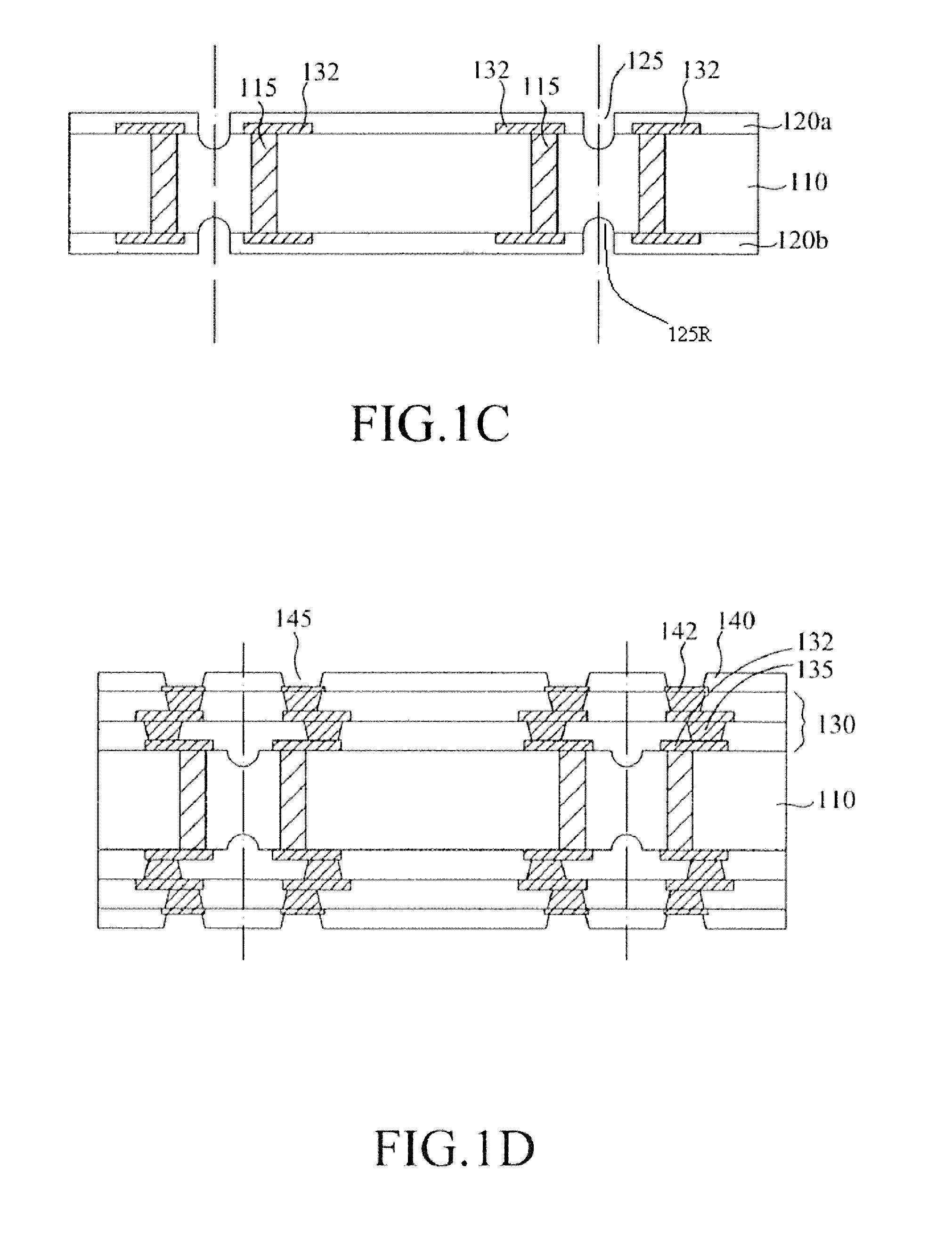

Substrate components for packaging IC chips and electronic device packages of the same

ActiveUS9478472B2Performed easily and efficientlyEfficient and convenient production3D rigid printed circuitsSemiconductor/solid-state device detailsEngineeringDielectric structure

Substrate components for packaging IC chips and electronic device packages are disclosed. A substrate component for packaging IC chips comprises: a glass core base with at least one conductive through via connecting a combination of metallization and dielectric structures on both an upper surface and a lower surface of the glass core base; and, tapered edges created at a peripheral region of the glass core base; wherein dielectric layers are disposed over the tapered edges at the peripheral region of the glass core base. In accordance with an embodiment of the invention, the dielectric layers have a substantial planar upper surface, a lower surface conformably interfaced with the tapered edges at peripheral region of the glass core base, and a steep cutting face with the tapered edges of the glass core base. Alternatively, the tapered edges at peripheral region of the glass core base are not covered by the dielectric layers, and an encapsulated material sealing the tapered edges at peripheral region of the glass core base.

Owner:HU DYI CHUNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com