A fiber guide device suitable for secondary plastic coating process

A secondary coating and process technology, applied in the field of optical cable processing, can solve the problems of unfavorable precise control of the excess length of the bundle tube, difficult control of the optical fiber, and increased workload, and achieve the effects of simple structure, accurate control, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

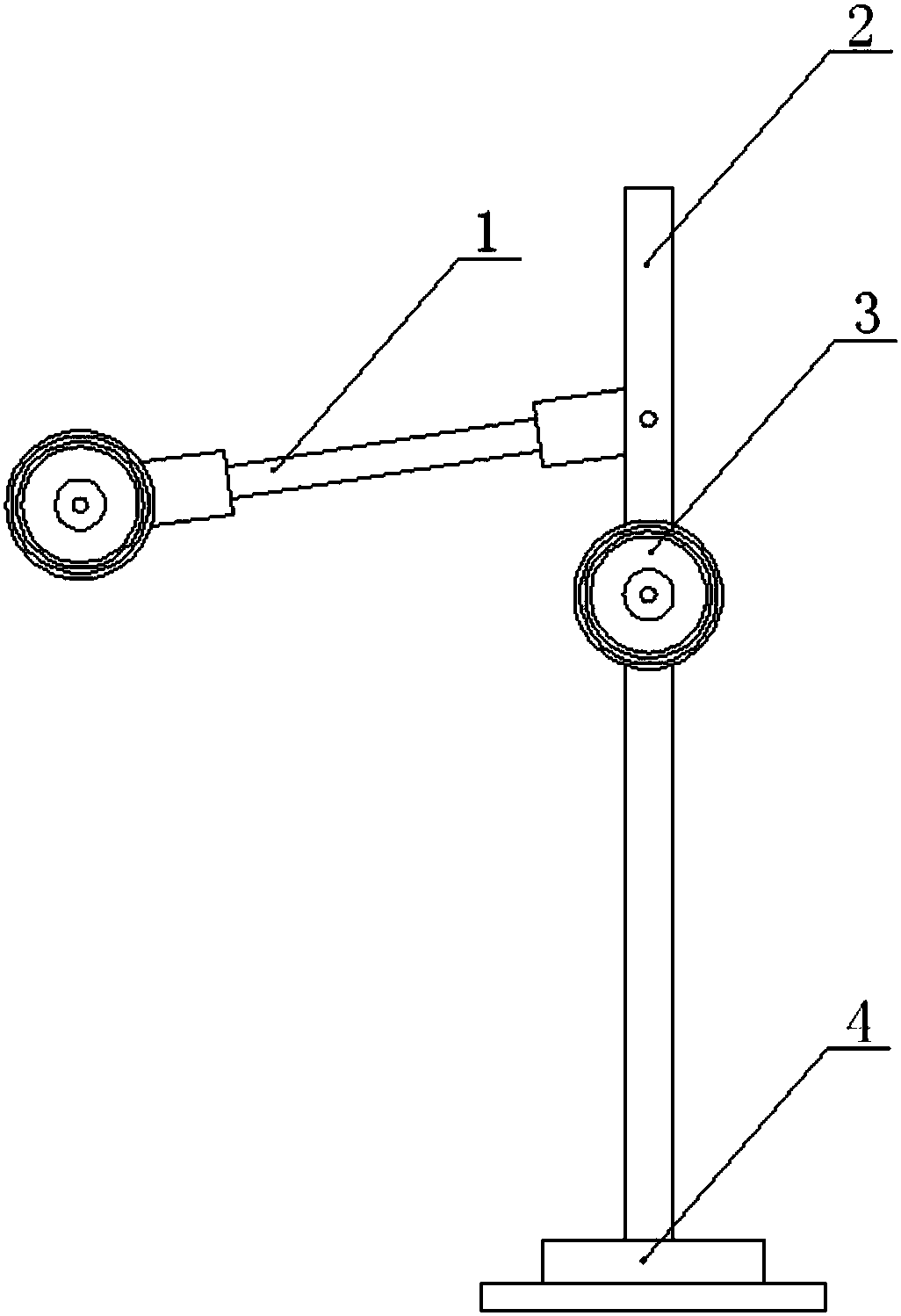

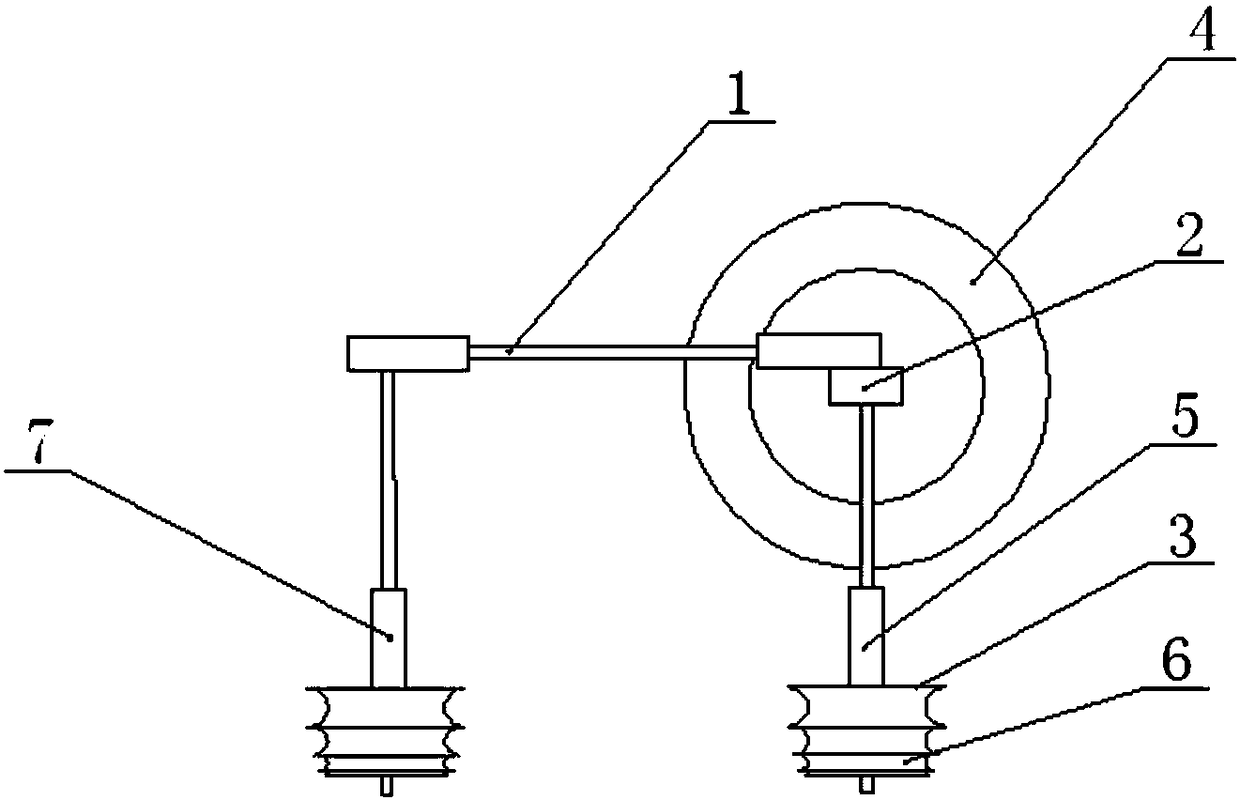

[0019] A fiber guide device suitable for the secondary molding process, such as figure 1 , figure 2 As shown, the device is composed of a floor stand, a telescopic rod and a guide wheel group 3, the floor stand is composed of a pole 2 and a base 4, and the telescopic rod is composed of an upper horizontal telescopic rod 1, a first telescopic rod 7 and a second telescopic rod 7. The guide wheel group is composed of several guide wheels with different diameters concentrically nested, and each guide wheel is surrounded by a wire groove 6. As the diameter of the guide wheel increases, the width of the corresponding wire groove increases accordingly. Big.

[0020] The pole is fixed vertically in the center of the base, and the upper horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com