A kind of copper oxide powder and preparation method thereof

A technology of copper oxide powder and oxidation reaction is applied in the field of metal powder, which can solve the problems that the uniformity and powder shape of copper oxide cannot be guaranteed, the use of copper oxide powder is affected, and the pollution is serious. , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] One aspect of the embodiments of the present invention provides a method for preparing copper oxide powder, which includes:

[0023] Smelt pure copper to a molten state, and directly atomize the molten copper in an oxygen atmosphere to fully oxidize copper and oxygen to obtain copper oxide powder.

[0024] As one of the preferred solutions, the melting temperature is 1400-1500° C., and the temperature is kept for 20-30 minutes.

[0025] As one of the preferred solutions, when the atomization treatment is performed, the pressure of the oxygen is 1.5-2.5 MPa. Within a certain range, the greater the pressure, the more thoroughly the powder can be pulverized and the finer powder can be obtained. When the oxygen pressure used in the production process is too low, on the one hand, it may lead to incomplete oxidation of copper oxide powder, and it may also cause the suction force in the negative pressure area of the nozzle to be too small, increasing the risk of furnace blo...

Embodiment 1

[0042] The method for preparing copper oxide powder of the present embodiment comprises the following steps:

[0043] A. Put the pure copper raw material into the gas atomization powder making equipment, first heat the pure copper to keep it warm, and then melt it to a molten state at 1400 ° C. The atomization powder making equipment can be obtained through commercial channels, etc., and will not be done here Too much detail.

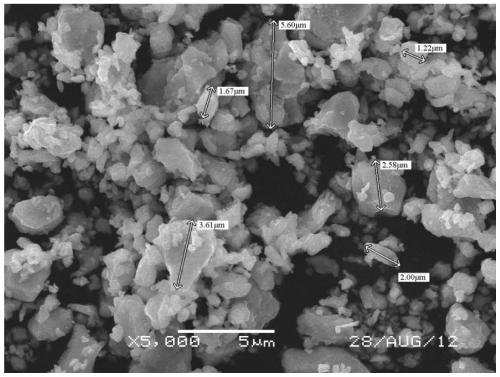

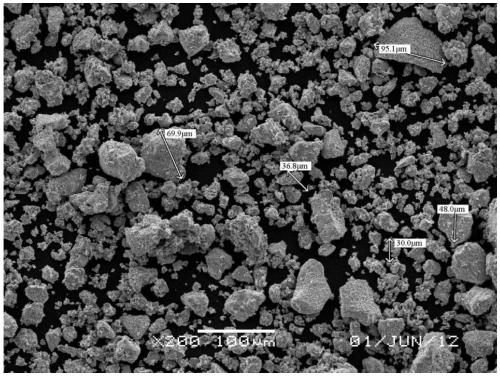

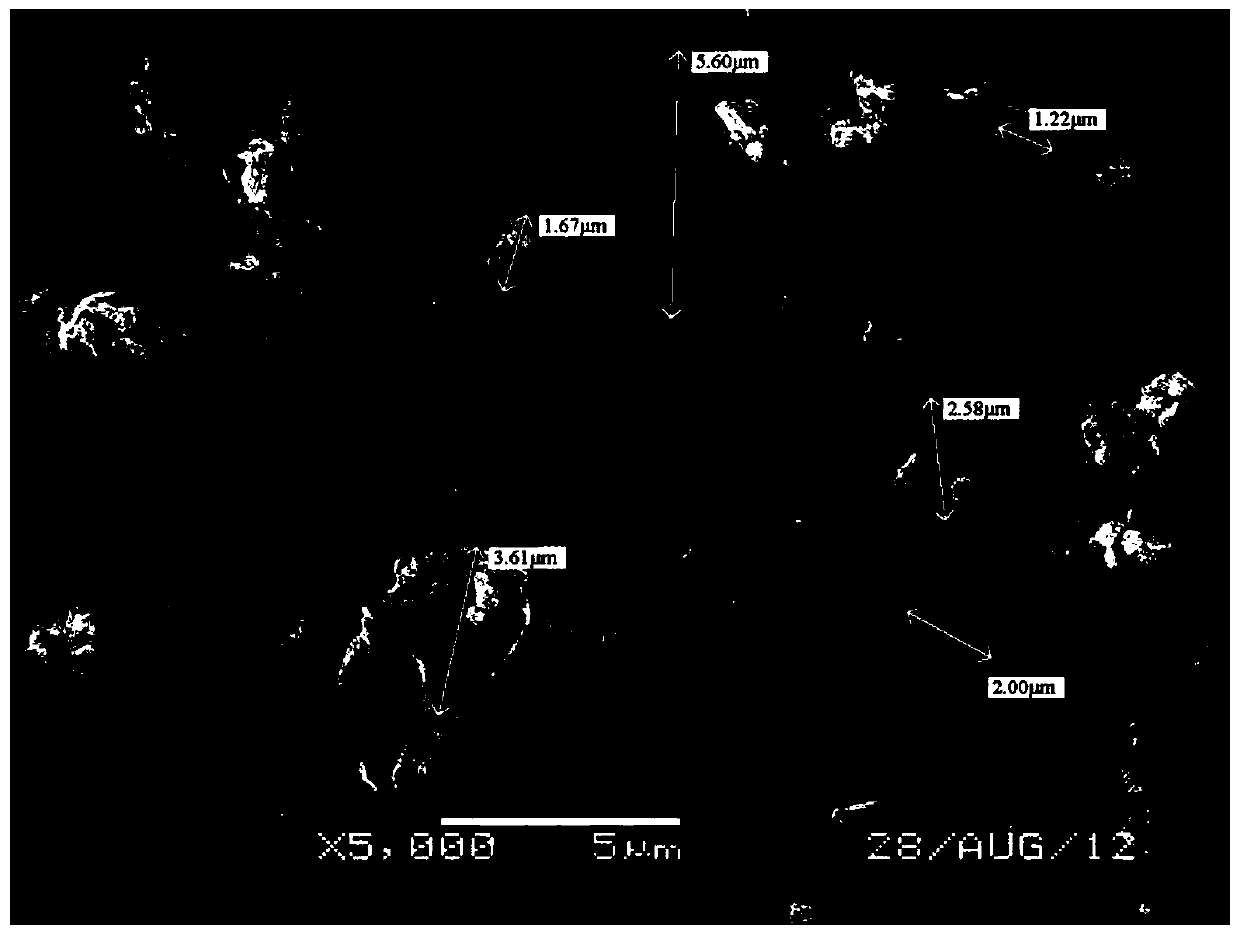

[0044] B. Atomize the molten pure copper material, feed pure oxygen gas, and the gas pressure is 1.5MPa to obtain copper oxide powder. The scanning electron microscope picture can be referred to figure 2 , and its particle size is 45-60 microns.

Embodiment 2

[0046] The method for preparing copper oxide powder of the present embodiment comprises the following steps:

[0047] A. Put the pure copper raw material into the gas atomization powder making equipment. First, heat the pure copper to keep it warm, and then melt it to a molten state at 1500 ° C. The atomization powder making equipment can be obtained through commercial channels, etc., and will not be done here. Too much detail.

[0048] B. Atomize the molten pure copper material, feed pure oxygen gas, the gas pressure is 2MPa, and make copper oxide powder, the scanning electron microscope picture can refer to figure 2 , and its particle size is 20-35 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com