Multi-channel piezoelectric 3D printing nozzle fault identification and status monitoring system and method

A 3D printing and fault identification technology, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve problems such as inability to effectively identify fault types, inability to monitor droplet velocity, and unfavorable corresponding measures. Save measurement time and space, improve detection accuracy, and achieve small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

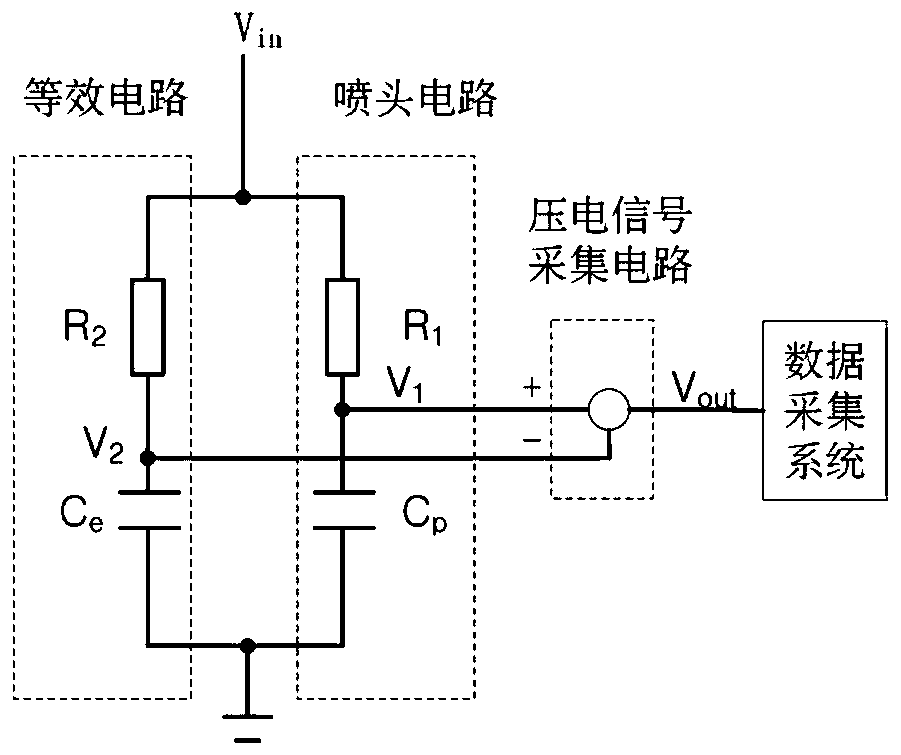

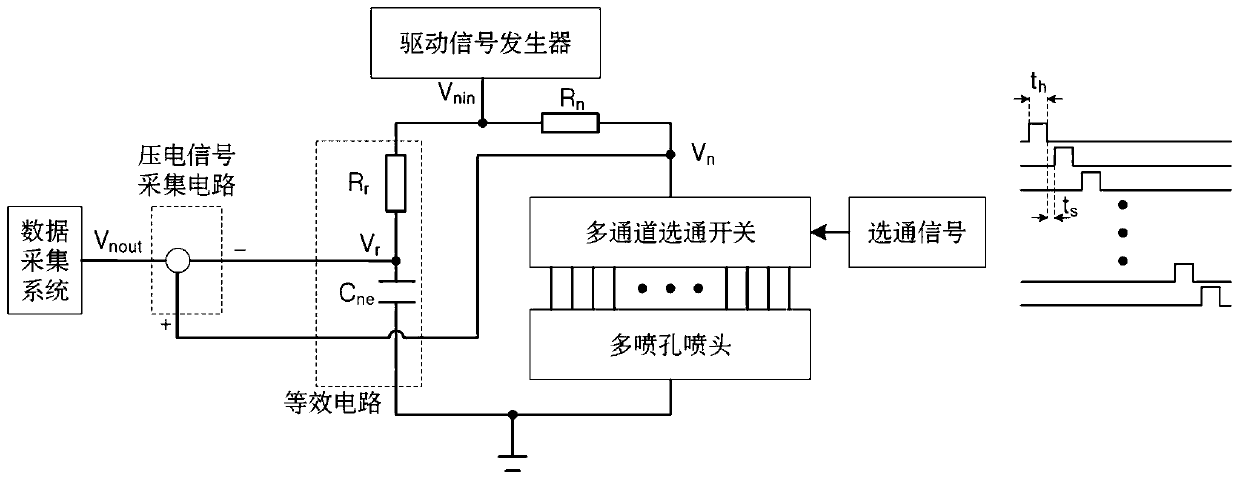

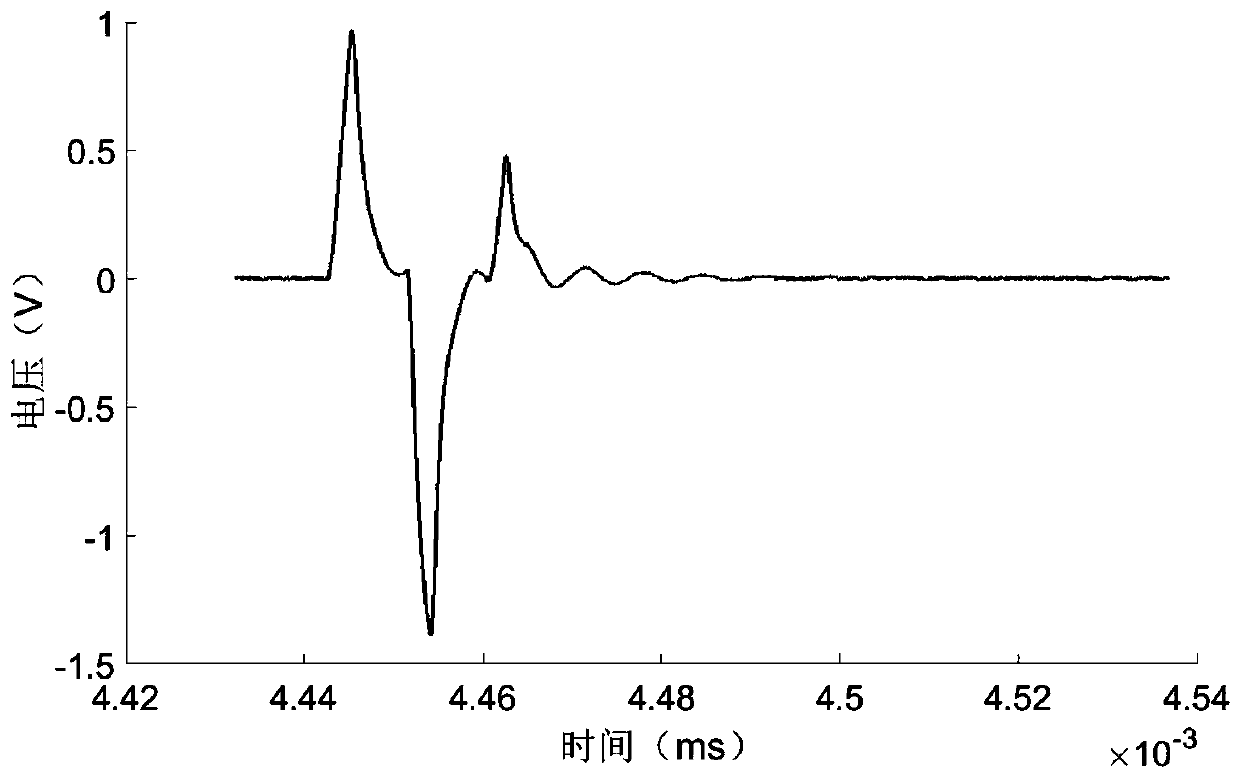

[0041] The present invention provides a multi-channel piezoelectric 3D printing nozzle fault identification and state monitoring system and method, using the self-induction detection method to convert the residual vibration signal in the flow channel cavity of the piezoelectric nozzle into a voltage signal for collection and analysis to obtain each The corresponding characteristic parameters when a fault occurs. If the characteristic parameter exceeds the threshold, it indicates that a fault has occurred. Judging the type of fault through the indicator light is convenient for taking processing measures. Compared with the traditional video-based spraying state monitoring method, the present invention can realize the monitoring of the spraying state of the spraying head during the printing process of the spraying head, without being limited by the position of the spraying head; Status monitoring greatly reduces hardware costs, improves detection efficiency and ensures the stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com