Integral type panel operation box and panel

A control box, integrated technology, applied in the field of elevator control equipment, can solve the problems of destroying the integrity of the control box panel, assembly efficiency, cost impact, complex structure of the maintenance door, etc., and achieve simple structure, high assembly efficiency and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

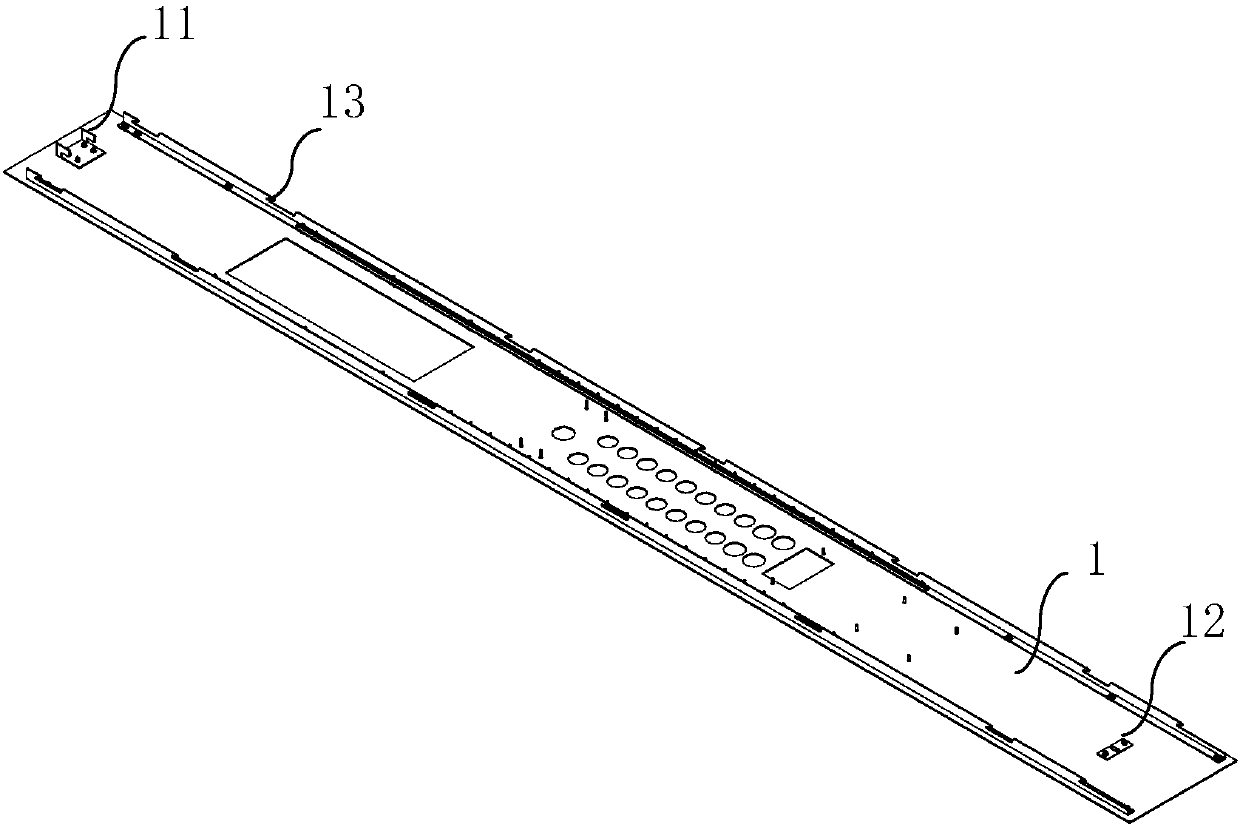

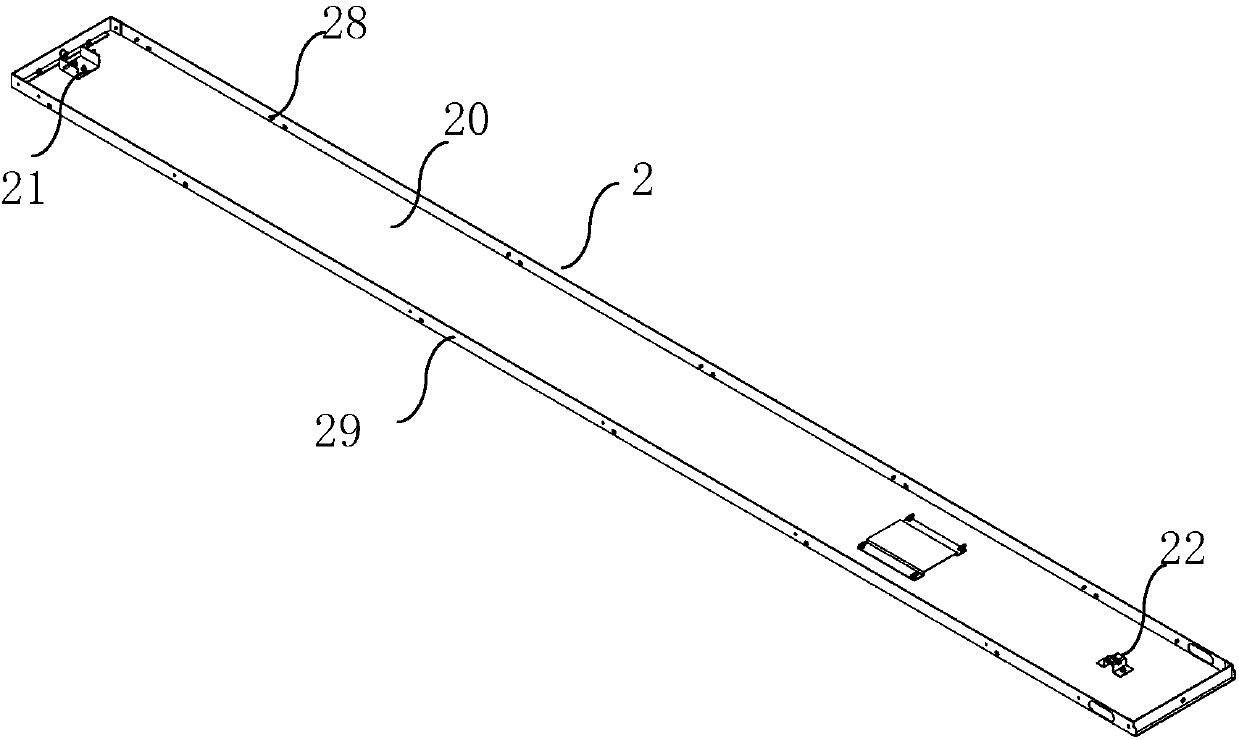

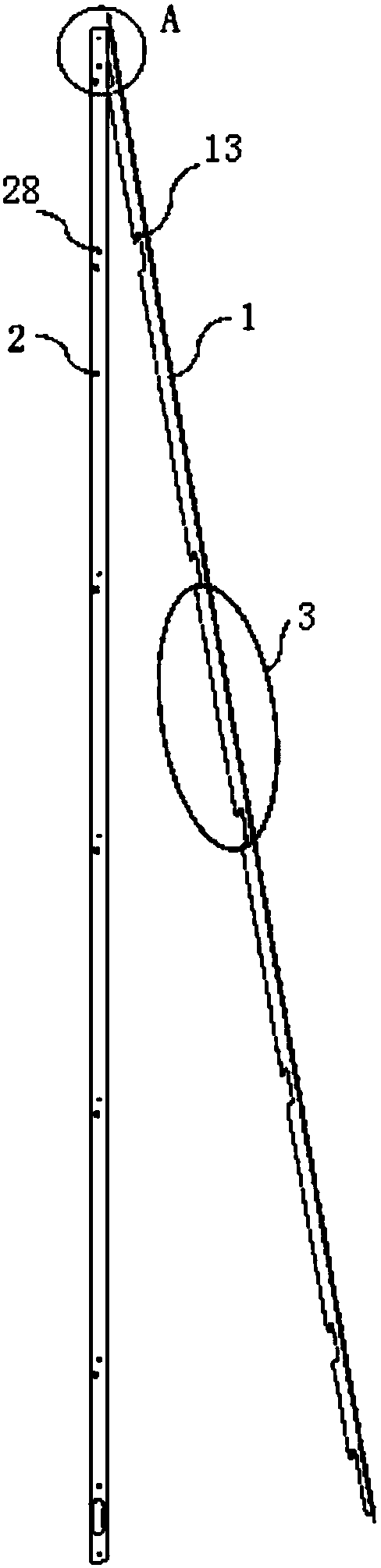

[0038] Such as figure 1 , figure 2 , image 3 As shown, the integral panel control box includes a panel 1 and a box body 2;

[0039] The panel 1 is provided with a swivel hook 11 on the side of the bottom plate close to the upper end, and a row of load-bearing hooks 13 with the heads facing down are respectively provided on the left and right sides;

[0040] The box body 2 includes a bottom plate 20 and a side wall plate 29;

[0041] The side wall plate 29 surrounds the panel side of the periphery of the bottom plate 2;

[0042] The bottom plate 20 is provided with a rotating shaft seat 21 on the panel side near the upper end;

[0043] The left and right side wall panels 29 are respectively provided with a row of bearing parts 28 facing the opposite side wall panels;

[0044] The swivel hook 11 on the panel 1 penetrates from the top between the horizontal rotation shaft 210 of the rotation shaft seat 21 and the bottom plate 20; Between the bearing part 28 on the side wa...

Embodiment 2

[0047] Based on the integral panel control box of embodiment one, as Figure 4 , Figure 5 , Figure 6 As shown, the swivel hook 11 includes a vertically connected horizontal portion 111 and a vertical portion 112;

[0048] The horizontal part 111 is fixed on the panel 1 , and a protruding hook head 110 is provided on the bottom plate side of the lower end surface of the vertical part 112 .

[0049] In the integral panel control box of the second embodiment, the head of the swivel hook 11 on the panel 1 is provided with a protruding hook head 110, which can effectively prevent the risk of falling off of the panel 1 during the process of turning into the box body 2; the vertical part of the swivel hook 11 112 and the panel 1 form an avoidance groove for avoiding the horizontal rotation shaft 210 of the rotating shaft seat 21, so as to ensure that the panel 1 and the box body 2 will not interfere with the rotating shaft seat 21 during the mating process, and the avoidance groo...

Embodiment 3

[0051] Based on the integral panel control box of embodiment one, as Figure 7 As shown, the bottom plate side of the lower part of the panel 1 is provided with a panel fixing base 12;

[0052] The panel side of the lower part of the bottom plate 20 is provided with a box fixing base 22;

[0053] The panel 1 is provided with an inspection hole 17 corresponding to the panel fixing base 12;

[0054] After the panel 1 is fastened together with the box body 2, the panel fixing base 12 forms an assembly relationship with the box body fixing base 22, and the panel fixing base 12 is connected to the box body fixing base 22 by bolts 19. To be fixed together, the panel 1 and the box body 2 are fixed.

[0055] Preferably, the diameter of the inspection hole 17 is not greater than 15mm.

[0056] Preferably, the panel 1 is also provided with button holes, display holes, and IC card holes.

[0057] In the integral panel control box of the third embodiment, the box fixing base 22 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com