Construction method of bamboo lattice lampshade

A construction method and bamboo weaving technology, applied in the field of architectural decoration, can solve the problems of the disclosure of the construction method of the bamboo weaving lattice lampshade and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036]EXAMPLES: A bamboo lattice lampshade construction method, steps below:

[0037]In the first step, the raw material treatment: first dip in the bamboo sheet in an alkali solution having a pH of 9.3, steaming at a temperature of 100 ° C for 2-4 hours, then the bamboo sheet is dried, and the glue contains 0.1%. Finally, the bamboo sheet is hot and the hot press temperature is 180-200 ° C, and the pressure is 100-120 MPa.

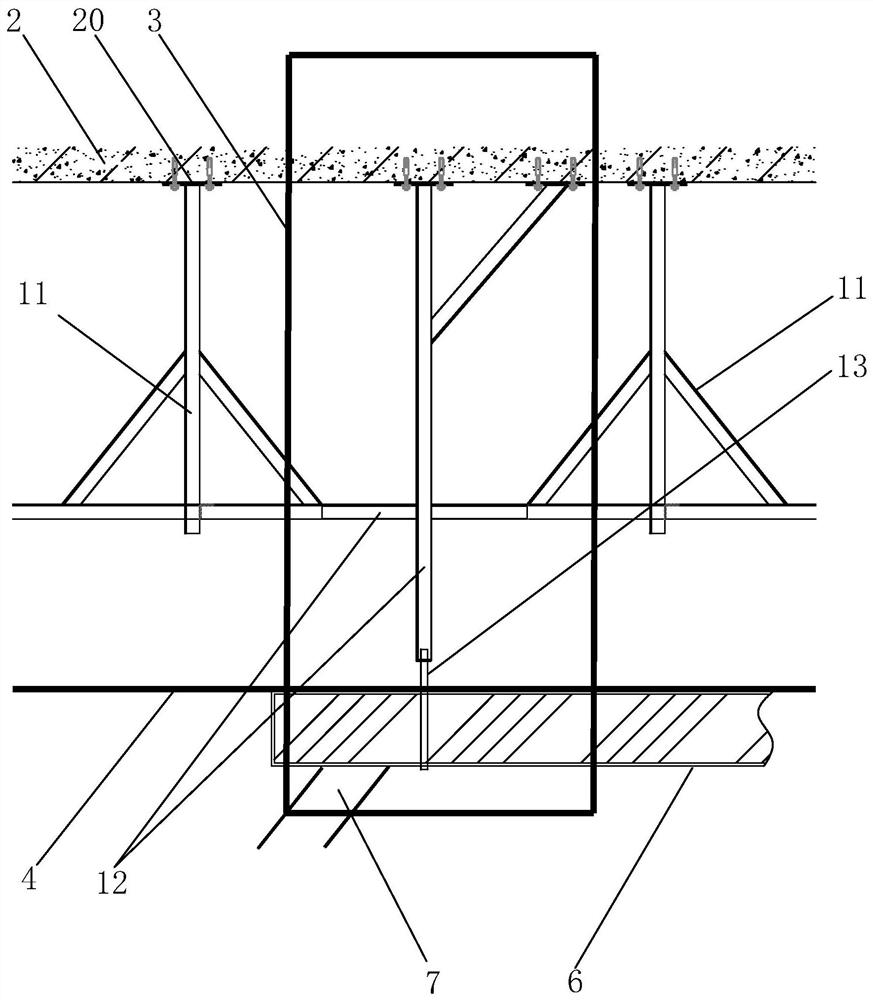

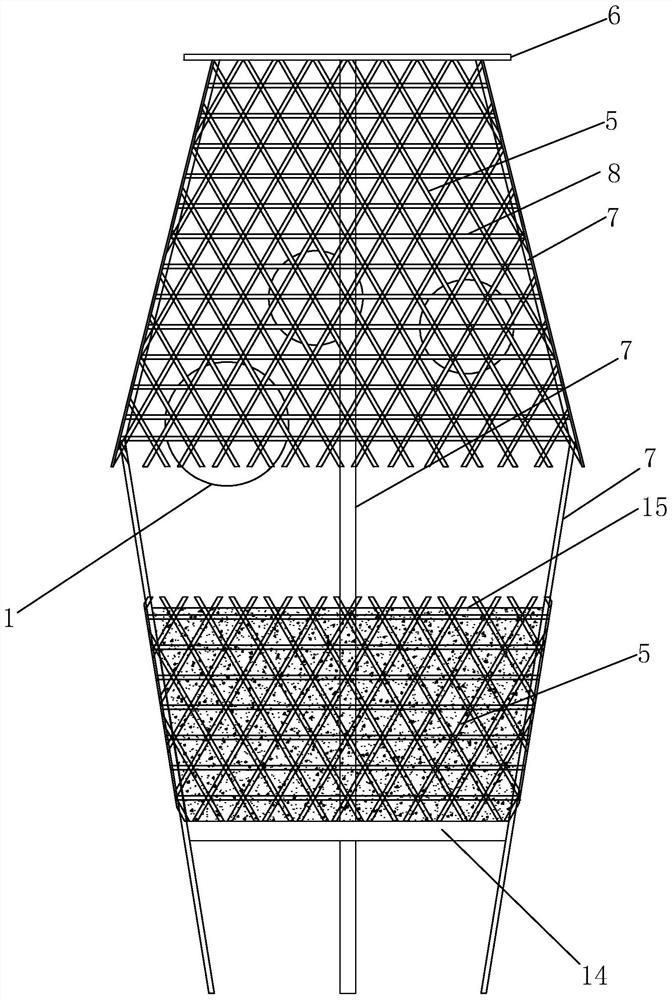

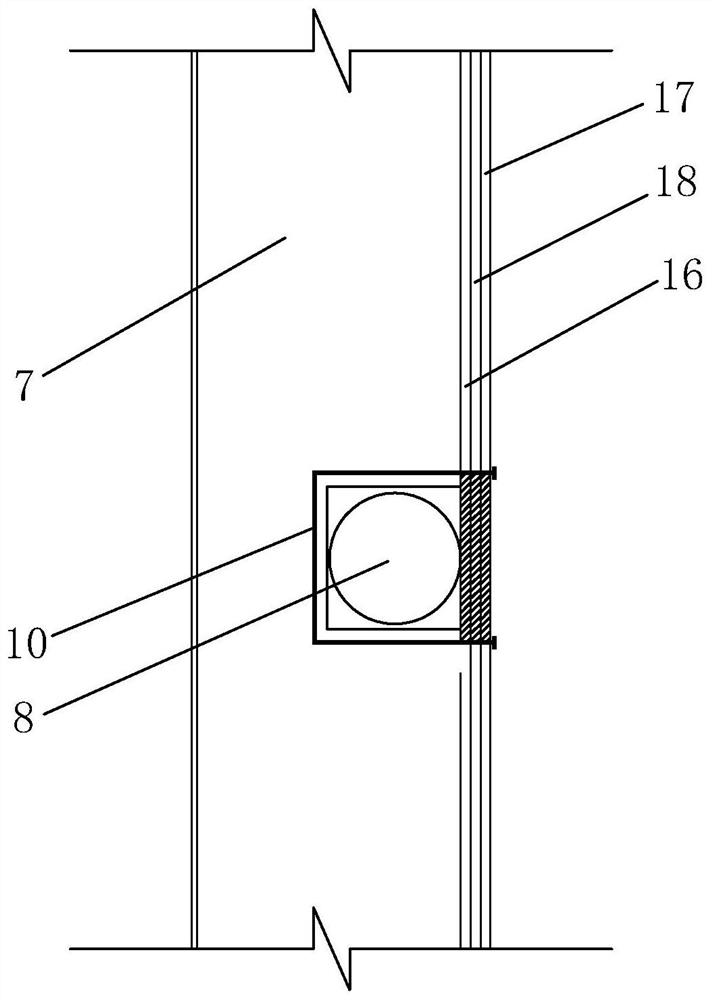

[0038]The second step, the embedded ceiling steel frame:figure 1 As shown, the top of the ceiling steel frame 3 is embedded in the floor 2, and the ceiling steel frame 3 extends to the ceiling completion surface 4 below the ceiling completion surface 4 below the surface of the ceiling, the ceiling steel frame 3 welding the ring main keel 6; in the floor surface of the floor 2 Expansive bolt fixing the galvanized burying plate 20, the upper surface welding of the galvanized burying plate 20, fixed galvanized angle steel connection frame 12, galvanized angle steel conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com