DST structure clutch cover tongue piece favorable for bending and forming and using method of DST structure clutch cover tongue piece

A clutch cover and tongue technology, applied in the field of auto parts manufacturing, can solve problems such as increasing production costs, affecting production efficiency, reducing bending stress, etc., and achieving the effects of saving production costs, protecting equipment from normal, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

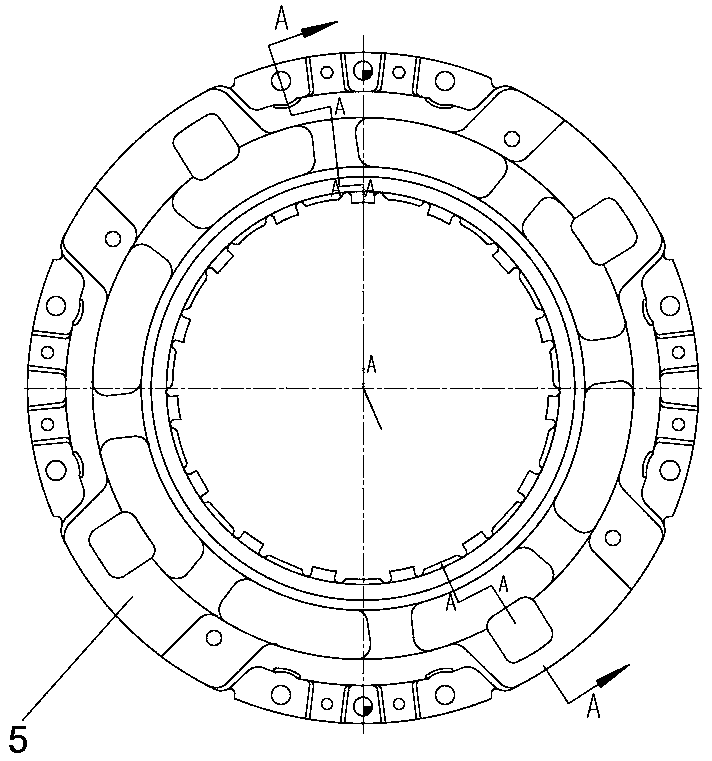

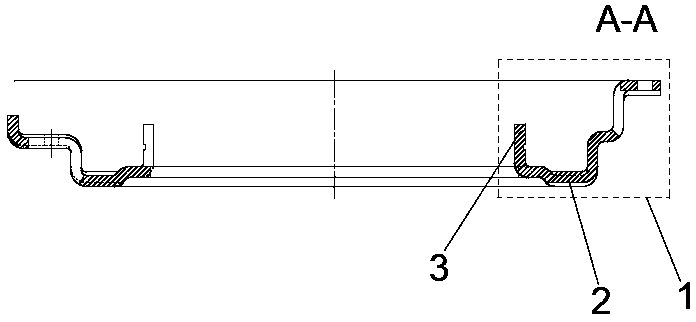

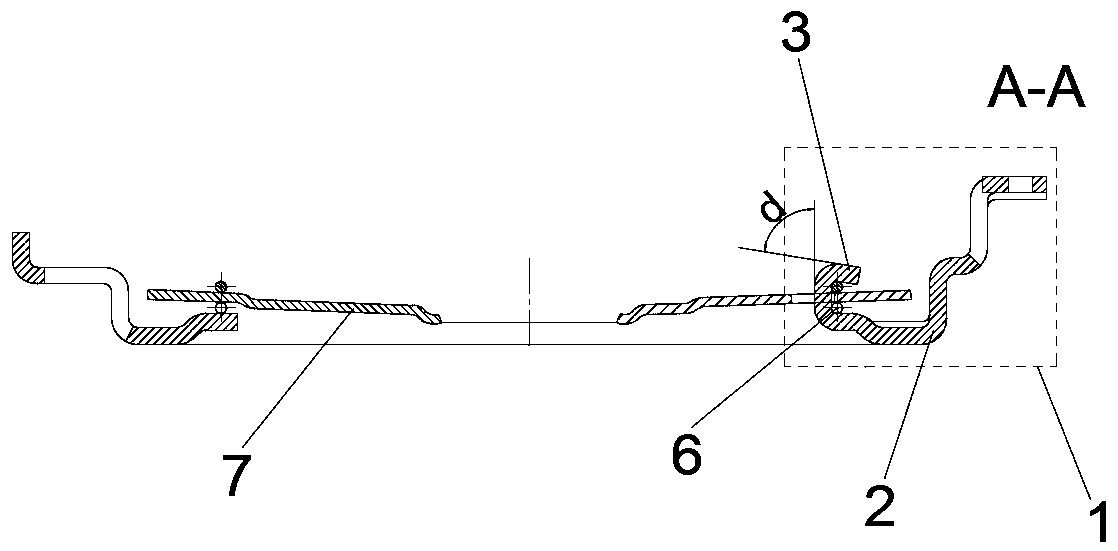

[0032] Such as Figure 1-5 As shown, a clutch cover tongue of a DST structure that facilitates bending and forming includes a tongue body 1; the workpiece to be assembled with the tongue body 1 includes a clutch cover assembly 5, a support ring 6 and a diaphragm spring 7 ; The tongue body 1 includes a bending area 2 and a deformation area 3; The structure is bent; the deformation zone 3 is provided with a bending groove 4 .

[0033] The bending groove 4 is arranged on the side of the deformation zone 3 , and is a through groove at both ends, passing through two opposite sides of the deformation zone 3 . The deformation zone 3 can be bent toward the opening direction of the bending groove 4 by taking the bending groove 4 as an apex.

[0034] The width a of the bending groove 4 ≥ the diameter of the support ring 6 . This size can ensure that the deformation zone 3 can reach a certain angle after being bent, and ensure that the tongue body 1 is not broken, and at the same time...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that the edge of the bending area 2 is tapered. The taper of the edge of the bending area 2 can reduce part of the stress and protect the tongue body 1 from being damaged.

[0043] The usage method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0045] The difference between this embodiment and embodiment 2 is that: the connection between the bending area 2 and the deformation area 3 is a round corner transition. Such a design can enhance the strength of the deformation zone 3 and make the deformation zone 3 less likely to be damaged during bending.

[0046] The usage method of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com