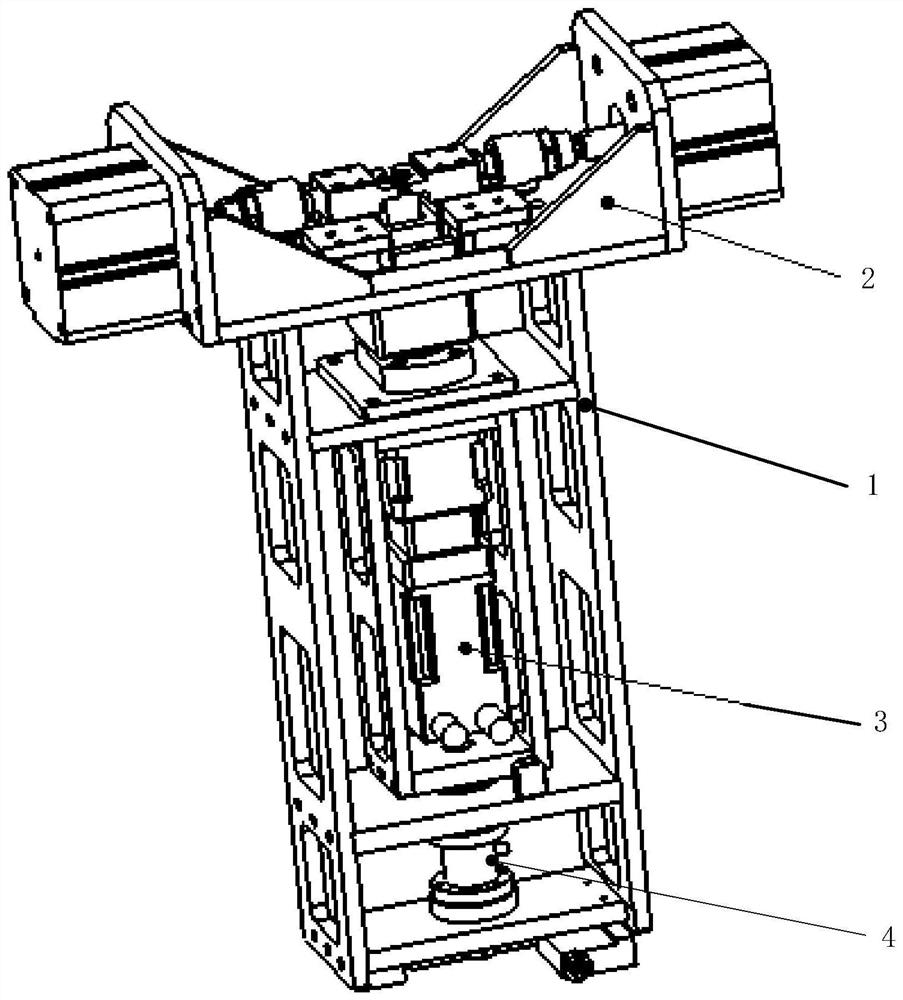

A torque detection mechanism and torque detection system

A technology of torque detection and static torque, which is applied in force/torque/power measuring instruments, measuring torque/torsion force during tightening, and measuring devices, etc. It can solve the problems of inability to accurately detect torque values, high detection costs, and inability to detect torque of special-shaped parts Value and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

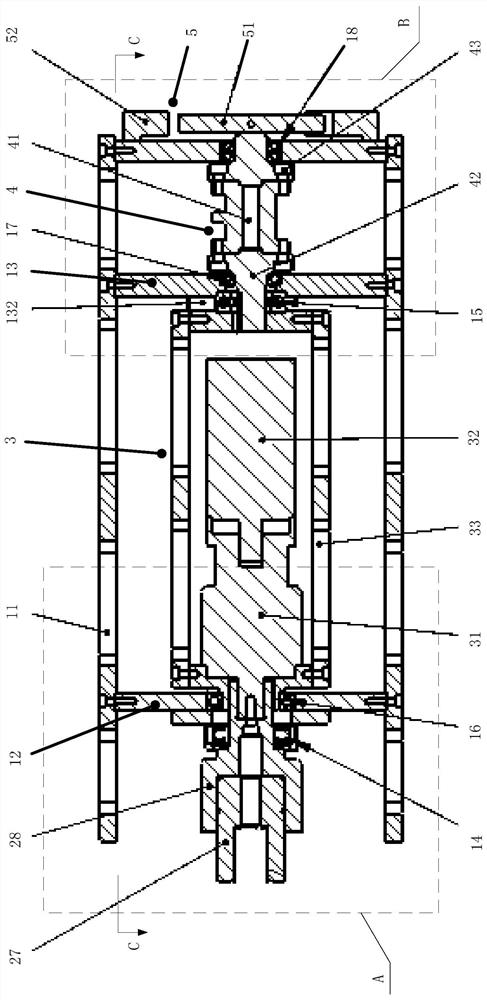

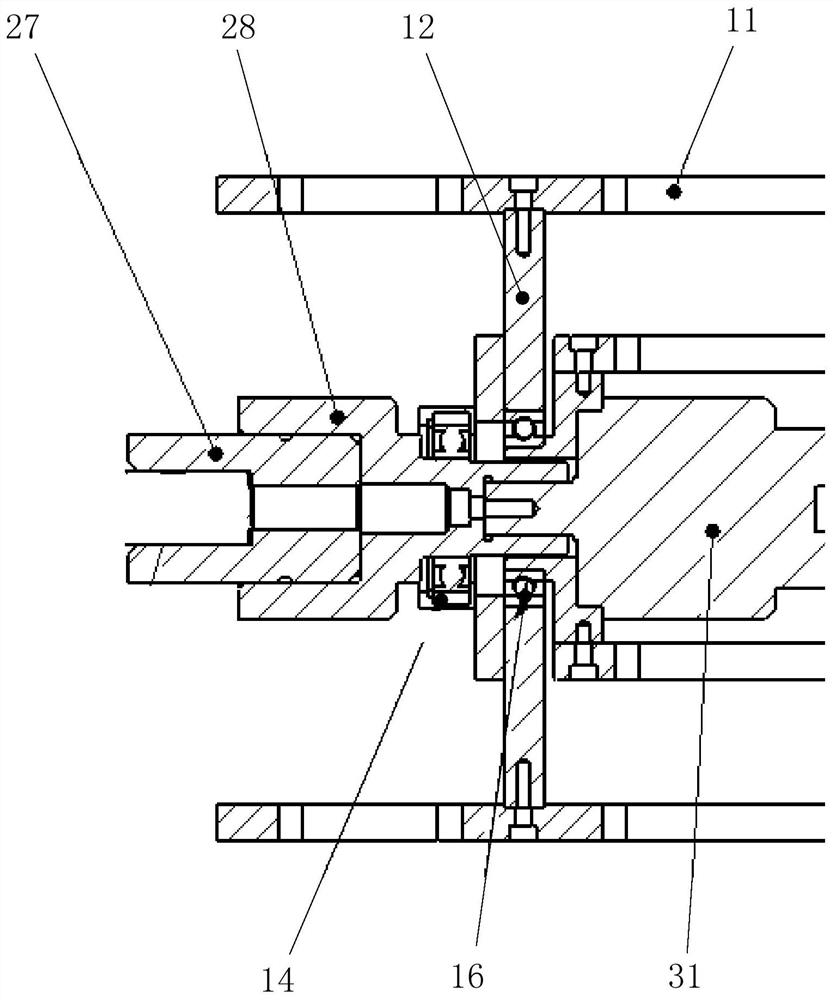

[0050] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

[0051] When the threaded structure is used, it needs to be tightened to a fixed torque value, but in the existing technical solutions, the detection cost of the torque value of the threaded structure is high or the torque value cannot be accurately detected, and it is not suitable for non-standard threads Torque values for class structures (i.e. shaped pieces). For this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com